Implant and preparation method and application thereof

A technology of implants and mixtures, applied in the field of implants, can solve problems such as repeated infections, infection lesions that cannot be eradicated, and little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] This embodiment has prepared a kind of implant, and specific process is:

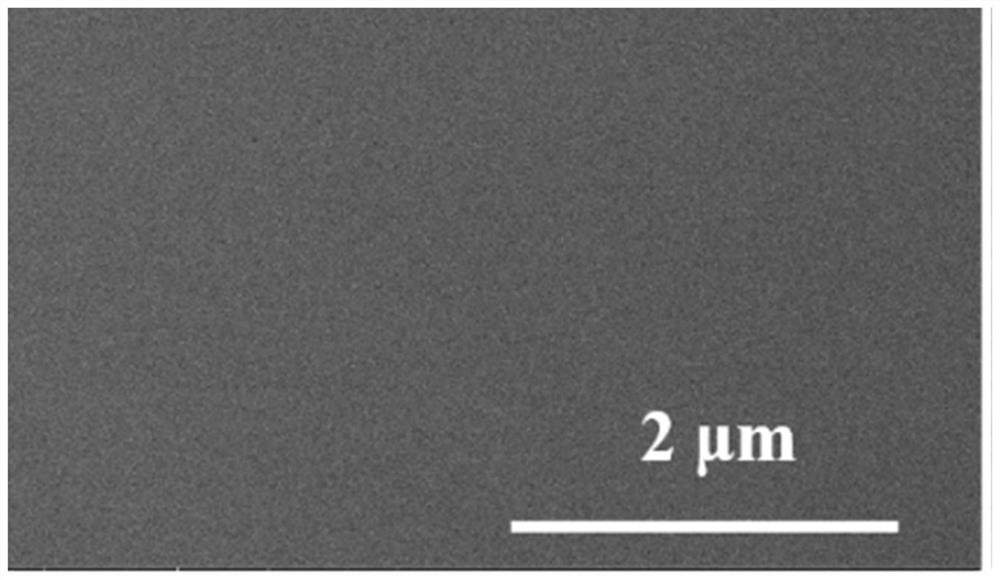

[0099] D1. Polish and ultrasonically clean the titanium-based raw material. After that, place the titanium-based raw material in deionized water, ultrasonically clean it for 5 minutes, repeat three times, and dry it;

[0100] D2. Alkali etching is carried out on the titanium-based raw material obtained in step D1. The etching solution contains 4mol / L potassium hydroxide; the reaction condition is 70°C; the reaction time is 3h; For deionized water, repeat three times to obtain a titanium-based matrix;

[0101] D3. Get curcumin and disperse it in deionized water to make 300 μ g / mL curcumin suspension, adjust the pH of the suspension to be 9, place the above-mentioned suspension on a magnetic stirrer and stir at a constant speed for 24h to make curcumin nanoparticles. DLS (dynamic scattering) and TEM record its particle size as 150 ± 30nm (particle size distribution within this range);

[0102] D4...

Embodiment 2

[0106] This embodiment has prepared a kind of implant, and specific process is:

[0107]D1. Polish and ultrasonically clean the titanium-based raw materials; after that, place the titanium-based raw materials in deionized water, ultrasonically clean for 5 minutes, repeat three times, and dry;

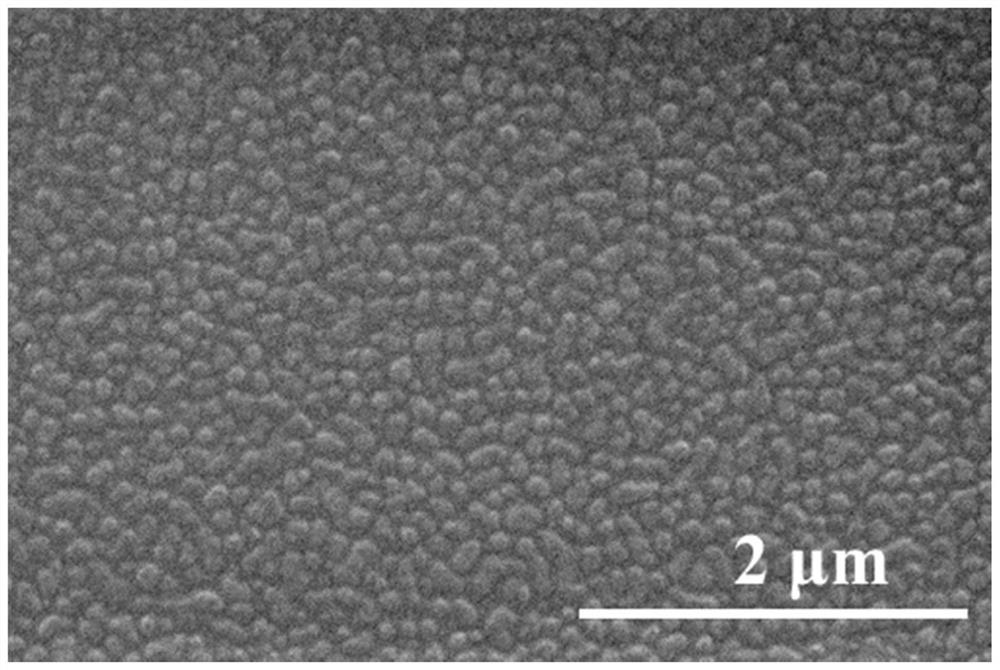

[0108] D2. Alkaline etching is carried out on the titanium-based raw material obtained in step D1. The etching solution contains potassium hydroxide of 10 mol / L; the reaction condition is 70°C; the reaction time is 3h; For deionized water, repeat three times to obtain a titanium-based matrix;

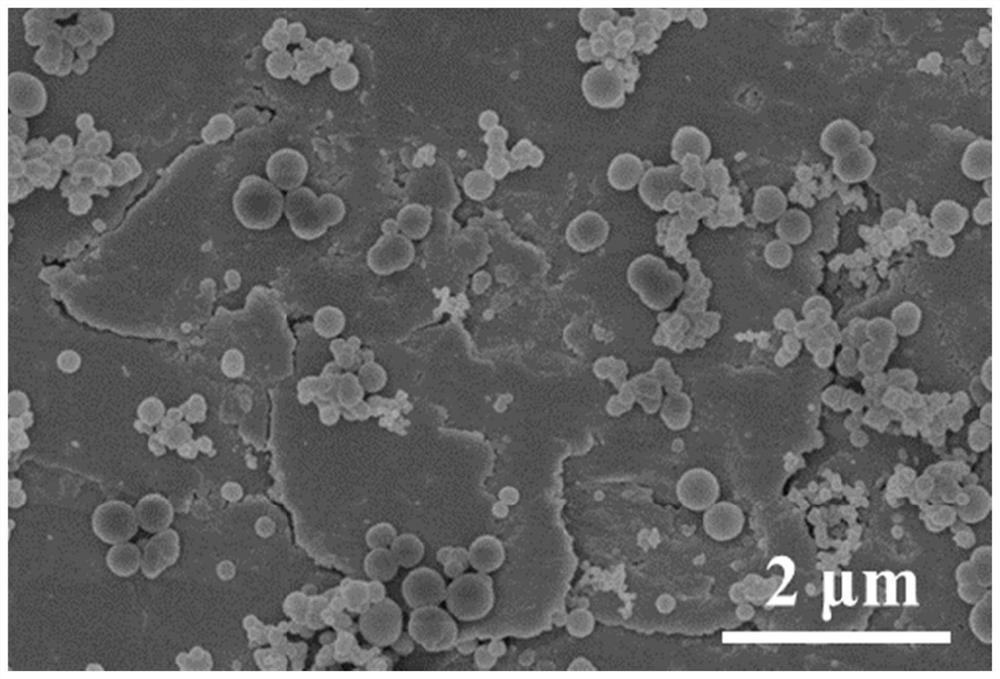

[0109] D3. Get curcumin and disperse it in deionized water to make 600 μ g / mL curcumin suspension, adjust the pH of the suspension to be 8, place the above suspension on a magnetic stirrer and stir at a constant speed for 24h to make curcumin nanoparticles. DLS (dynamic scattering) and TEM record its particle size as 650 ± 50nm (particle size distribution within this range);

[0110] D4. Take t...

Embodiment 3

[0114] This embodiment has prepared a kind of implant, and specific process is:

[0115] D1. Polish and ultrasonically clean the titanium-based raw materials; after that, place the titanium-based raw materials in deionized water, ultrasonically clean for 5 minutes, repeat three times, and dry;

[0116] D2. Alkaline etching is carried out on the titanium-based raw material obtained in step D1. The etching solution contains potassium hydroxide of 10 mol / L; the reaction condition is 70°C; the reaction time is 3h; For deionized water, repeat three times to obtain a titanium-based matrix;

[0117] D3. Get curcumin and disperse it in deionized water to make a curcumin suspension of 50 μg / mL, adjust the pH of the suspension to be 7, place the above-mentioned suspension on a magnetic stirrer and stir at a constant speed for 24h to make curcumin nanoparticles. DLS (dynamic scattering) and TEM record its particle size as 60 ± 5nm (particle size distribution within this range);

[0118...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com