Cation rectification system for fine screening of special cations and application of cation rectification system

A rectification system and refined sieve technology, applied in the field of cationic rectification, can solve the problems that the characteristics of continuous operation cannot be effectively reflected, limit the separation efficiency of target ions, and unsatisfactory screening performance, so as to reduce the requirements of its own characteristics, Reduce the cost of preparation and research and development, and improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

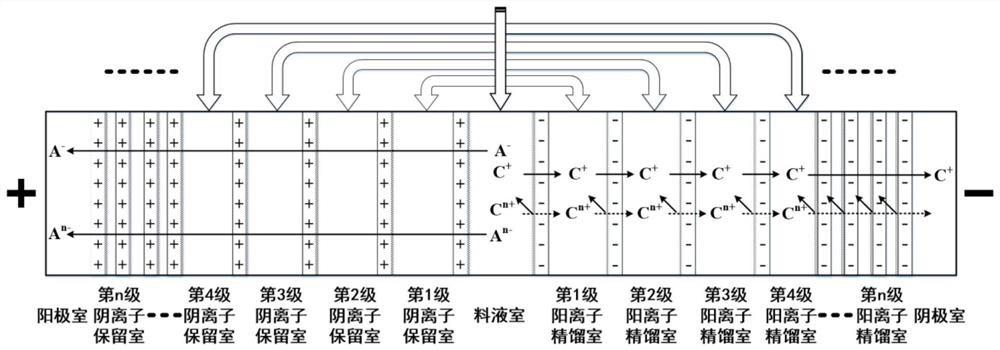

Method used

Image

Examples

Embodiment 1

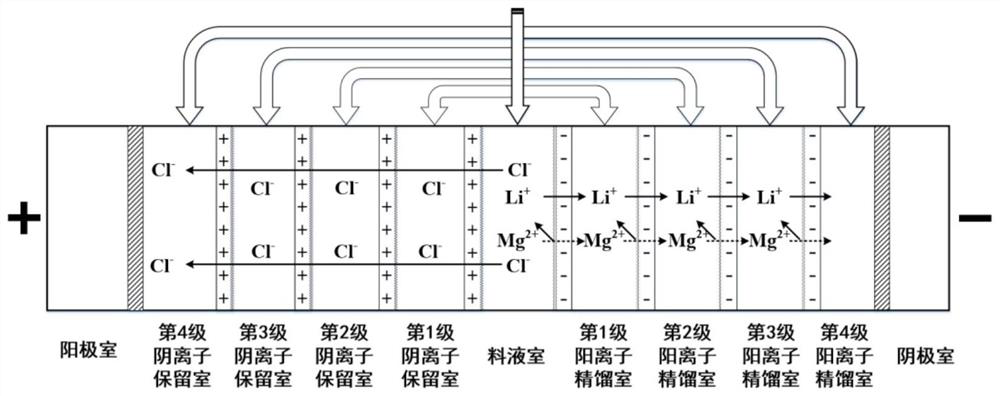

[0057] This embodiment utilizes the above-mentioned cation rectification system to process the + , Mg 2+ with Cl - For the mixed material liquid of ions, the cation rectification system adopted is a four-stage cation rectification system, and the number of cation rectification units is 1. The first-stage cation rectification chamber communicates with the first-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump; the second-stage cation rectification chamber communicates with the second-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump; the third stage The first-stage cation rectification chamber communicates with the third-stage anion retention chamber, and the circulating flow is driven by a solution-driven pump; the fourth-stage cation rectification chamber communicates with the fourth-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump; the anode chambe...

Embodiment 2

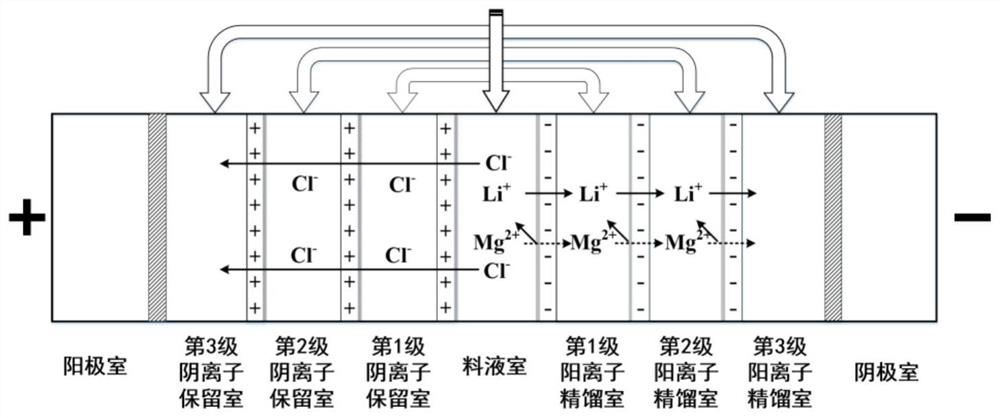

[0061] This embodiment utilizes the above-mentioned cation rectification system to process the + , Mg 2+ with Cl - For the mixed material liquid of ions, the cation rectification system adopted is a three-stage cation rectification system, and the number of cation rectification units is 1; the first-stage cation rectification chamber communicates with the first-stage anion retention chamber, and is driven by a solution-driven pump Circulating flow; the second-stage cationic rectification chamber communicates with the second-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump; the third-stage cationic rectification chamber communicates with the third-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump ; The anode chamber communicates with the cathode chamber, and the circulation flow is driven by a solution-driven pump. The three-stage cation rectification system consists of 3 one-multivalent cati...

Embodiment 3

[0065] This embodiment utilizes the above-mentioned cation rectification system to process the + , Mg 2+ with Cl - For the mixed material liquid of ions, the cation rectification system adopted is a two-stage cation rectification system, and the number of cation rectification units is 1; the first-stage cation rectification chamber communicates with the first-stage anion retention chamber, and is driven by a solution-driven pump Circulating flow; the second-stage cation rectification chamber communicates with the second-stage anion retention chamber, and the circulation flow is driven by a solution-driven pump; the anode chamber communicates with the cathode chamber, and the circulation flow is driven by a solution-driven pump. The two-stage cation rectification system consists of 2 one-multivalent cation selective membranes and 4 anion exchange membranes (two of which are used as end-capping diaphragms); 2 ruthenium-iridium electrodes are placed at both ends of the cation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com