Preparation method of silk-free cloisonne

A cloisonne and silk scene technology, applied in the field of preparation of silk-free cloisonne, can solve the problems of copper wire falling off, cloisonne filigree, repeated rework, etc., and achieve the effects of improving production efficiency, saving processes and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

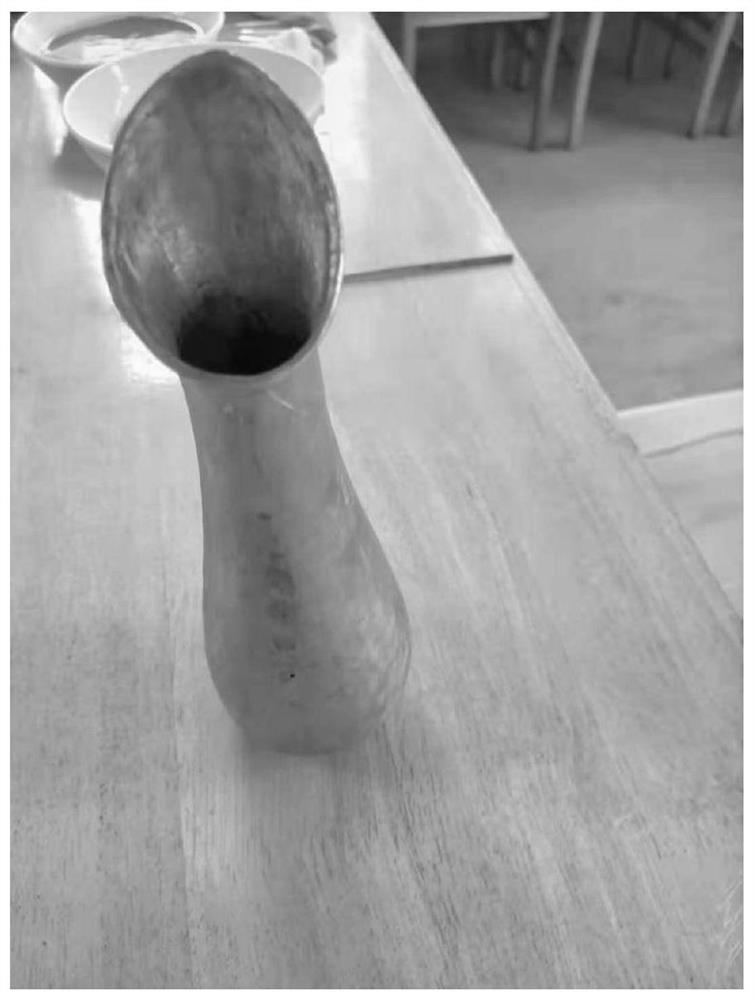

[0040] The application provides a method for preparing silkless cloisonné, which includes tire making, bluing, bluing, polishing and gold plating.

[0041] Further, the concrete steps of tire making are as follows:

[0042] Determine the design scheme of cloisonné, and use pure copper as the carcass material to prepare copper tires according to the design scheme.

[0043] Before deciding to make an aesthetic work, the most important thing is to determine the design plan. Design the tire shape and style of the copper tire. Since cloisonne is limited by the carcass technology and glaze, the designer must not only have a certain art knowledge and painting foundation, but also be familiar with the production process of cloisonne, and understand the use of various raw materials. Performance, the characteristics of the production process can be fully considered in the creation and design, so that the cloisonné has an overall natural beauty.

[0044] Tire making is to heat and soft...

Embodiment 1

[0065] A preparation method of silkless cloisonne, comprising the following steps:

[0066] (1) determine the design scheme of cloisonné, and prepare the copper tire according to the design scheme with pure copper as the carcass material;

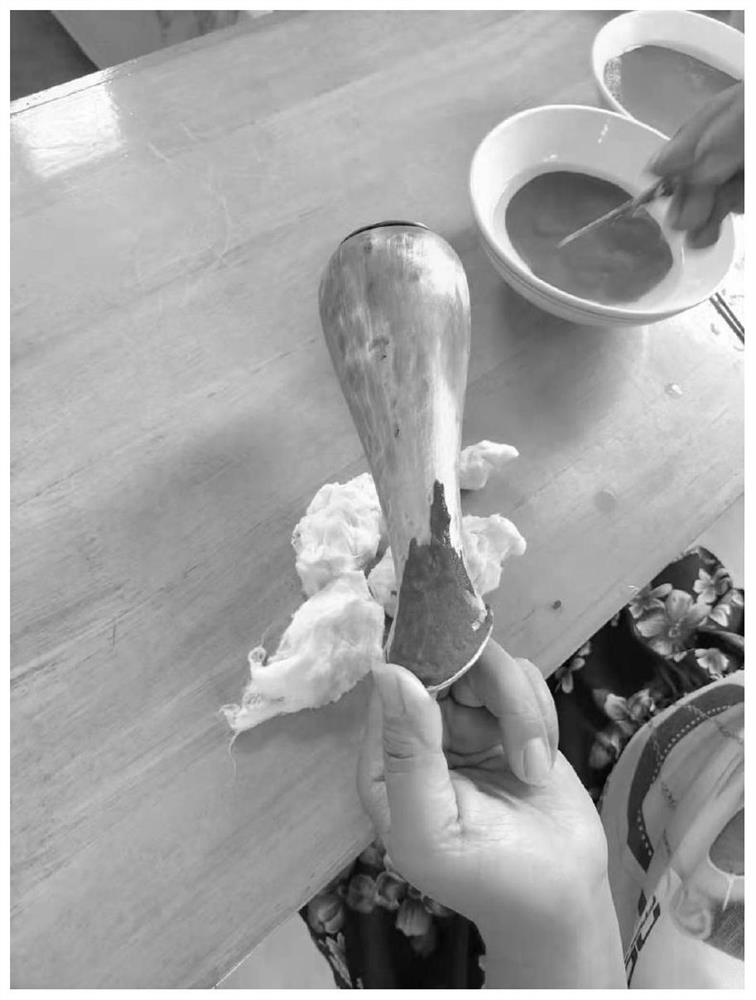

[0067] (2) Grind the required glaze through an 80-mesh sieve, and carefully wash the glaze used for indigo until there are no impurities visible to the naked eye. Dry the washed glaze in a cool place and put it in a bowl. Add clear water into the bowl and stir well. The mass ratio of the glaze in the bowl to the added clear water is 1:1. Then use a blue straw to draw the glaze in the bowl and apply it on the carcass, and use a blue gun to spread it evenly on the The surface of the copper tire is painted. During the coloring period, the colored glaze part can be kept from cracking by spraying water with a watering can, and the thickness of the glaze coated on the surface of the copper tire is 1mm when a single spot is blued;

[0068] (3) Pr...

Embodiment 2

[0073] A preparation method of zero filigree cloisonne, comprising the following steps:

[0074] (1) determine the design scheme of cloisonné, and prepare the copper tire according to the design scheme with pure copper as the carcass material;

[0075] (2) Grind the required glaze through a 90-mesh sieve, and carefully wash the glaze used for indigo until no impurities are visible to the naked eye. Dry the washed glaze in a cool place and put it in a bowl. Add clear water into the bowl and stir well, the mass ratio of the glaze in the bowl to the added clear water is 1:1.5, then use a bluing suction to suck up the glaze in the bowl and apply it on the surface of the carcass and apply it evenly on the surface of the carcass with a bluing gun The surface of the copper tire is painted, and the colored glaze part is kept from cracking during the coloring period, and the thickness of the glaze coated on the surface of the copper tire is 3mm when a single blue spot is applied;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com