Viscosity reduction and solid removal integrated device for catalytic cracking oil slurry

A catalytic cracking oil slurry and viscosity reduction technology, which is applied in the multi-stage series refining process treatment, etc., can solve the problems of affecting desolidification and poor viscosity reduction effect, and achieves high operating flexibility, easy control, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention can be explained in detail through the following technical solutions, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

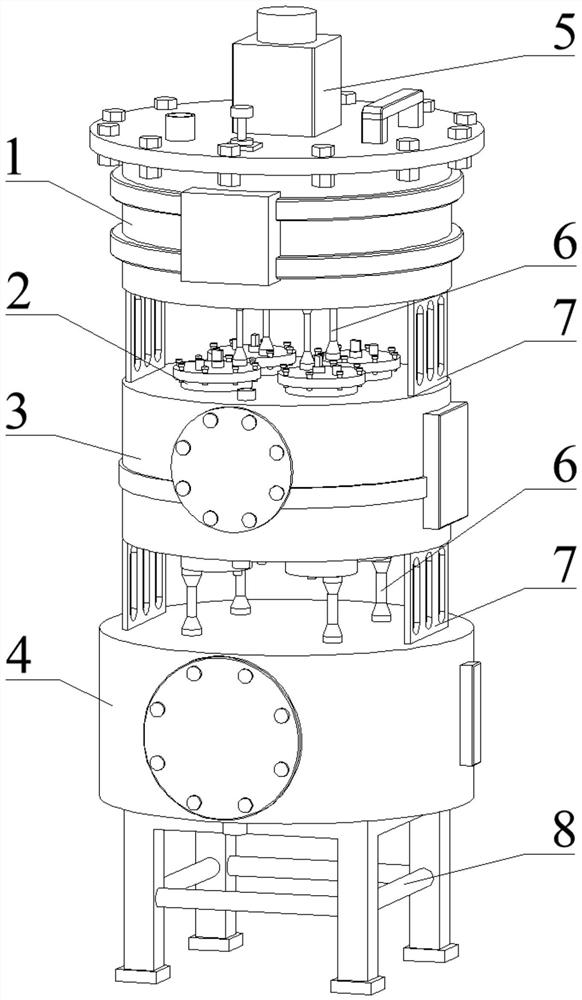

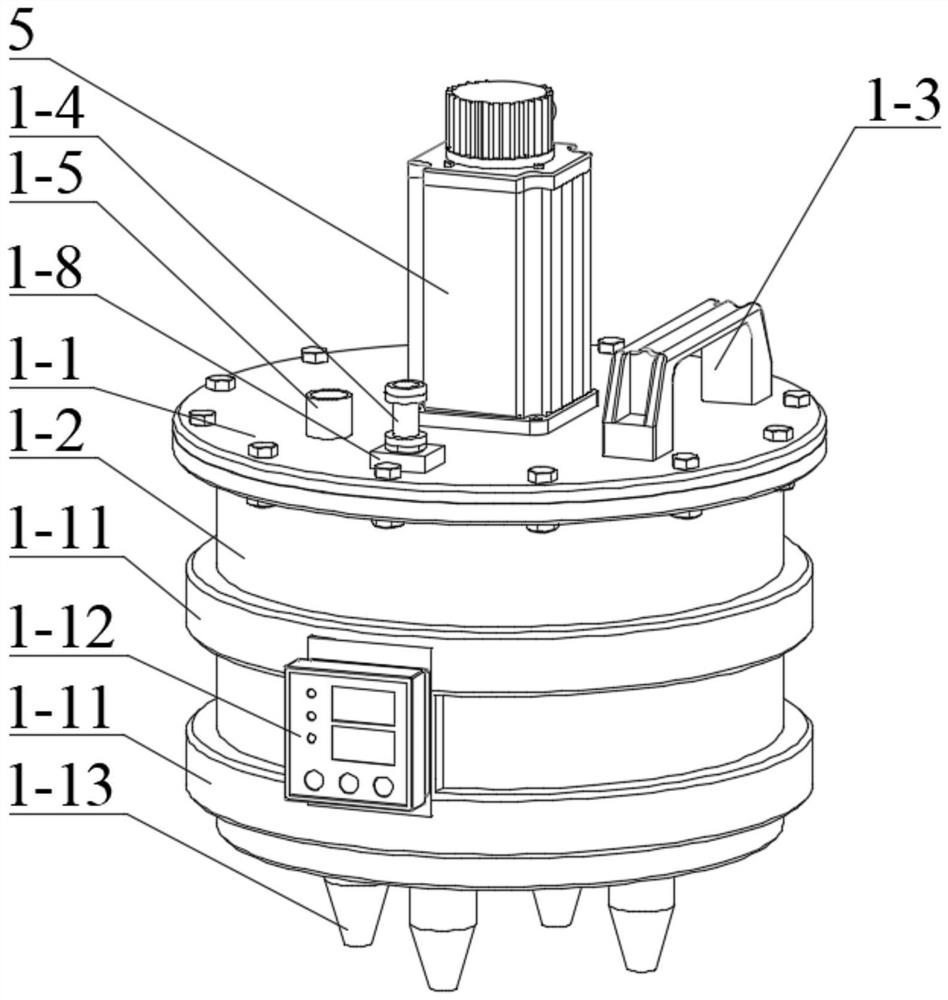

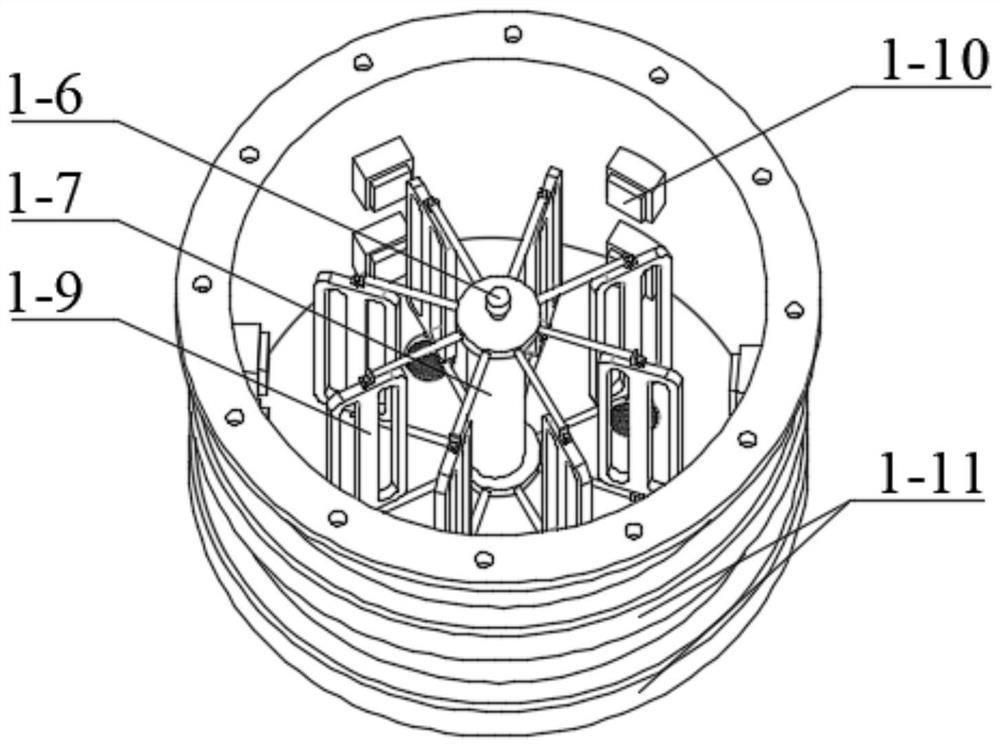

[0045] figure 1 It is a schematic diagram of the overall structure of the device of the present invention. As shown in the figure, the integrated device for viscosity reduction and desolidification of catalytic cracking oil slurry of the present invention includes an ultrasonic viscosity reduction tank 1, an electrostatic separation tank 2, a constant temperature water bath tank 3 and an oil storage tank. Tank 4, the constant temperature water bath tank 3 is set above the oil storage tank 4 through the support frame 7, the ultrasonic viscosity reduction tank 1 is set above the constant temperature water bath tank 3 through the support frame 7, and the electrostatic separation tank 2 is installed on the constant temperature water bath Inside the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com