Superfine grinding and enzymolysis production process of instant ganoderma sinense tea

A technology of ultrafine pulverization and production technology, which is applied in tea, tea extraction, food science, etc., can solve the problems of difficult absorption of active ingredients, large loss of functional ingredients, and influence on market expansion, and achieve full taste, large release and absorption, The effect of good market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

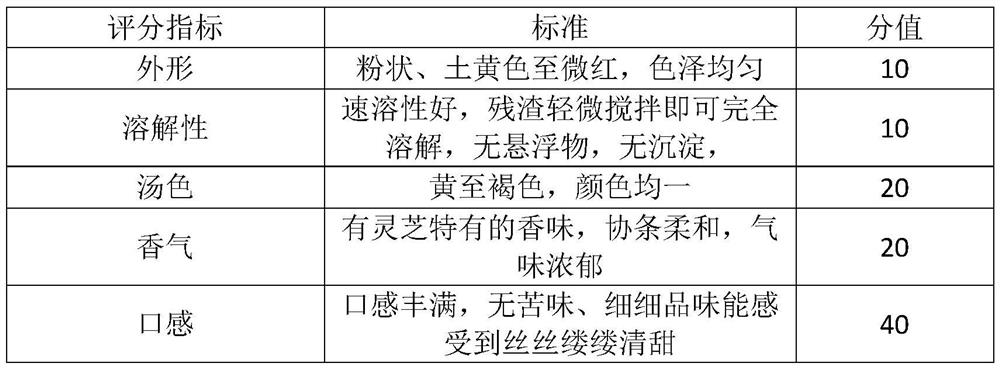

Examples

Embodiment 1

[0025] A kind of purple ganoderma lucidum instant tea superfine pulverization enzymatic hydrolysis production process, comprises the following steps:

[0026] (1) Dry, pulverize, and pass through a 20-mesh sieve, then superfinely pulverize the purple ganoderma to a particle size of no more than 2 μm, dissolve in water at a ratio of 1:10 g / mL, and then add 5% NSP enzyme-laccase (NSP enzyme The ratio of laccase and laccase is 20:1, pH5.0) mixed enzyme solution, 40 ℃ enzymatic hydrolysis for 12h, and then boiled for 30min, filtered and collected while hot, adding 8 times the volume of water to the filter residue, boiled for 1h, while Filtrate hot, combine the filtrates and concentrate to 1 / 3 of the original volume with a rotary evaporator to obtain Ganoderma lucidum concentrate;

[0027] Note: NSP enzyme and its activity composition: cellulase activity 2000U / g, pectinase activity 300U / g, xylanase activity 10000U / g, β-glucanase activity 1000U / g, mannanase activity 200U / g;

[002...

Embodiment 2

[0034] A kind of purple ganoderma lucidum instant tea superfine pulverization enzymatic hydrolysis production process, comprises the following steps:

[0035] (1) Dry, pulverize, and pass through a 40-mesh sieve, then superfinely pulverize the purple ganoderma to a particle size of no more than 2 μm, dissolve in water at a ratio of 1:15g / mL, and then add 7% NSP enzyme-laccase (NSP enzyme The ratio of laccase and laccase is 10:1, pH5.0) mixed enzyme solution, enzymolysis at 30°C for 12h, then boiling for extraction for 40min, filtering and collecting while hot, adding 9 times the volume of water to the filter residue, boiling for 1.5h, Filtrate while hot, combine the filtrates and concentrate to 1 / 3 of the original volume with a rotary evaporator to obtain Ganoderma lucidum concentrate;

[0036] Note: NSP enzyme and its activity composition: cellulase activity 4000U / g, pectinase activity 100U / g, xylanase activity 20000U / g, β-glucanase activity 1000U / g, mannanase activity 300U / ...

Embodiment 3

[0043]A kind of purple ganoderma lucidum instant tea superfine pulverization enzymatic hydrolysis production process, comprises the following steps:

[0044] (1) Dry, pulverize, and pass through a 30-mesh sieve, then superfinely pulverize the purple ganoderma to a particle size of no more than 2 μm, dissolve in water at a ratio of 1:12g / mL, and then add 4% NSP enzyme-laccase (NSP enzyme The ratio of laccase and laccase is 15:1, pH5.5) mixed enzyme solution, enzymatic hydrolysis at 35°C for 10h, and then boiled for extraction for 30min, filtered and collected while hot, adding 8 times the volume of water to the filter residue, boiled for 1-1.5 h, filter while hot, combine the filtrates and concentrate to 1 / 3 of the original volume with a rotary evaporator to obtain a Ganoderma lucidum concentrate;

[0045] Note: NSP enzyme and its activity composition: cellulase activity 3000U / g, pectinase activity 200U / g, xylanase activity 15000U / g, β-glucanase activity 1200U / g, mannanase acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com