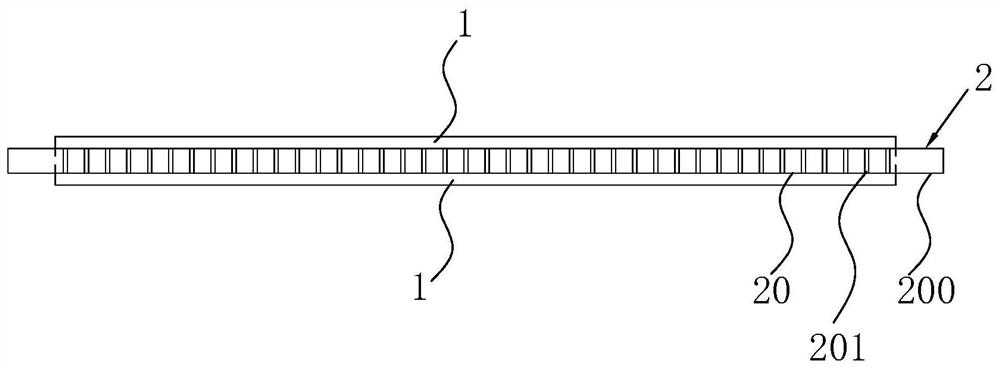

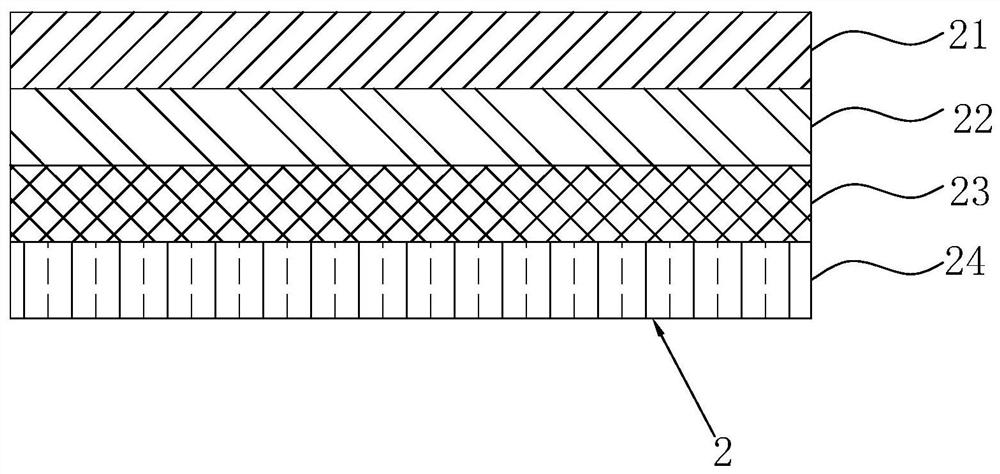

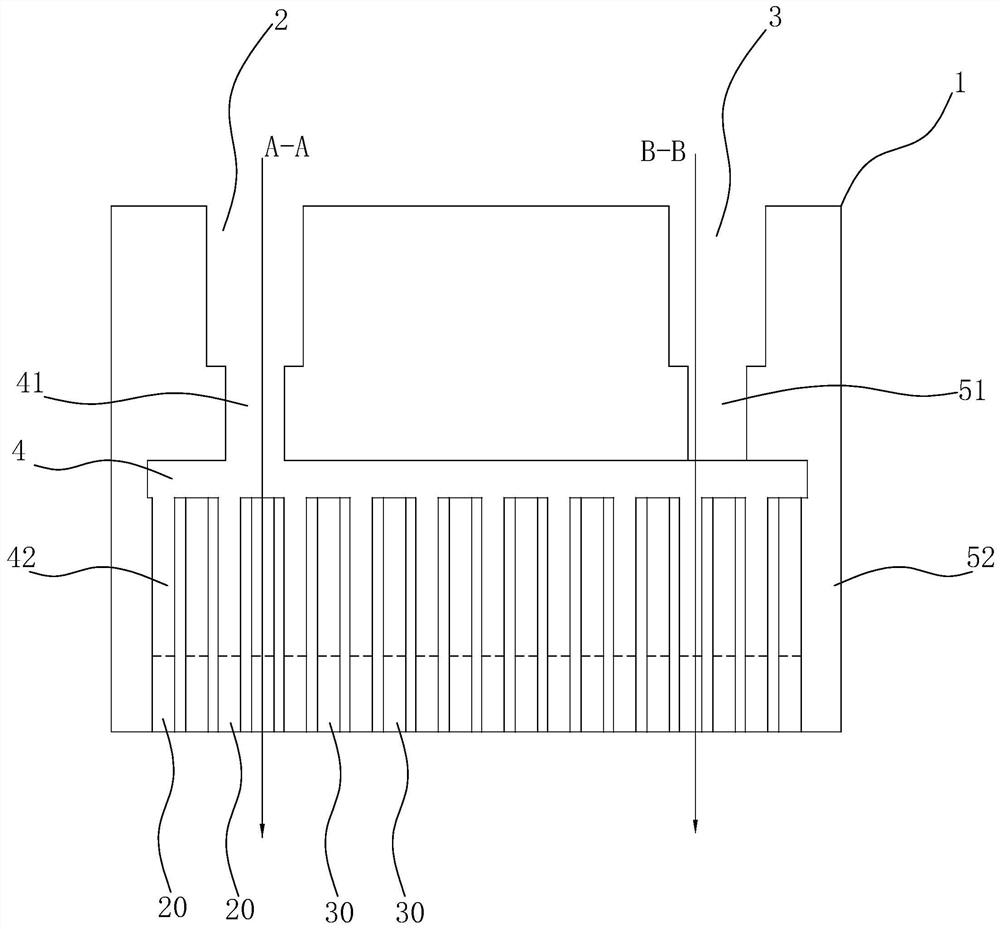

Visual easy-to-tear food packaging film and preparation process thereof

A food packaging film and film layer technology, which is applied in the field of food packaging materials, can solve the problems of increased moisture permeability and decreased film transparency, and achieves the effect of simple preparation and operation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0081] The anti-fog masterbatch is prepared from 6.0kg of linear low density polyethylene, 3.0k of triglycerol monostearate, and 1.0kg of genuine BASF polyethylene wax emulsion. Among them, the preparation of anti-fog masterbatch: blend 6.0kg of linear low density polyethylene, 3.0k of triglycerol monostearate, and 1.0kg of genuine BASF polyethylene wax emulsion, and add them to the twin-screw extruder , extruded at an extrusion temperature of 204°C, and granulated to obtain an anti-fog masterbatch with a particle size of 1.0-1.2mm.

preparation example 2

[0083] The antibacterial masterbatch is prepared from 6.0kg of linear low density polyethylene, 3.0kg of sodium dehydroacetate and 1.0kg of calcium propionate. Among them, the preparation of antibacterial masterbatch: 6.0kg of linear low density polyethylene, 3.0kg of sodium dehydroacetate, and 1.0kg of calcium propionate were blended, added to a twin-screw extruder, and extruded at a temperature of 205°C. out and granulated to obtain an antibacterial masterbatch with a particle size of 1.0-1.2mm.

preparation example 3

[0085] Preparation of breathable masterbatch: first blend 1.2kg of low-density polyethylene, 3.0kg of linear low-density polyethylene, and 1.8kg of metallocene linear low-density polyethylene, and then blend with 4.0kg of calcium carbonate, add into a twin-screw extruder, extruded at an extrusion temperature of 202°C, and granulated to obtain a breathable masterbatch A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com