Compression-resistant carbonization-resistant recycled concrete and preparation method thereof

A technology for recycled concrete and anti-carbonization, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Compressive strength, reduced rust, improved carbonation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of anti-compression and anti-carbonation recycled concrete, including the following raw materials: ordinary Portland cement 310kg; fly ash 57kg; recycled coarse aggregate 980kg; fine aggregate 690kg; water reducing agent 4kg; water 130kg; 40kg; sodium carboxymethylcellulose 5kg; 4A zeolite 24kg.

[0058] Among them, the strength grade of ordinary Portland cement is 52.5; the continuous particle size of recycled coarse aggregate is 5-20mm; the particle size of nano-silica is 20nm.

[0059] A preparation method of anti-compression and anti-carbonation recycled concrete, comprising the following steps:

[0060] S1. Take ordinary Portland cement, fine aggregate and water according to the above weight, and mix ordinary Portland cement, fine aggregate and two-thirds of water through a mixer at a speed of 1.6m / s. 45s, until mixed evenly, to obtain the mixture A; take the regenerated coarse aggregate, sodium carboxymethylcellulose, 4A zeolite and the remaining water acc...

Embodiment 2

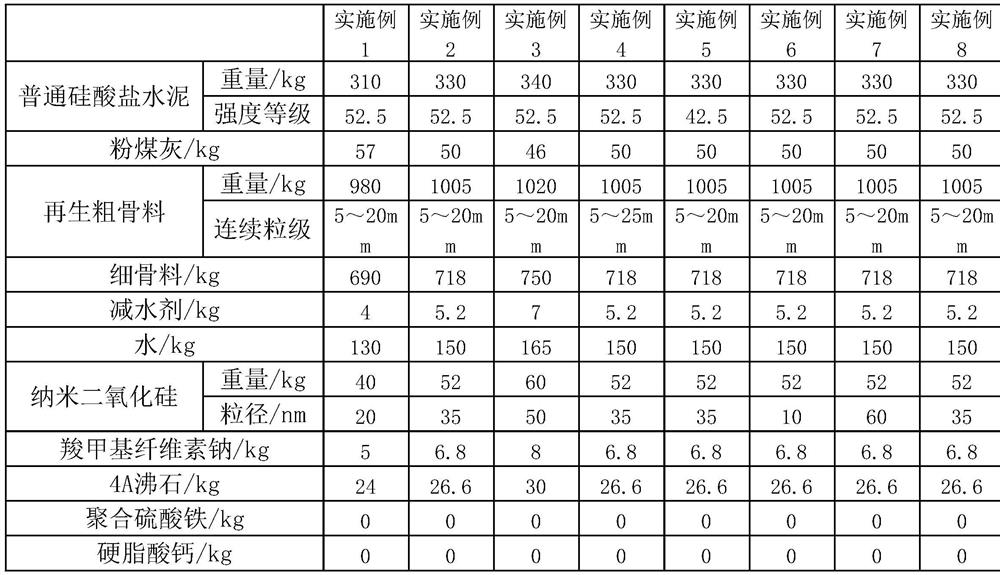

[0064] The difference between embodiment 2, embodiment 3 and embodiment 1 is: the weight and specifications of each raw material are different, see Table 1 for details.

Embodiment 4

[0066] The difference between this example and Example 2 is that the continuous particle size of the recycled coarse aggregate in this example is 5-25 mm, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com