Preparation method of cannabidivarin crystal

A technology of cannabidiol and cannabidiol oil, which is applied in the field of industrial preparation of cannabinoid crystals, can solve the unfavorable transportation, storage and use of cannabidiol products, which are difficult to meet safety supervision departments, and are not suitable for large-scale production Application and other issues, to achieve the effect of low cost, low consumption and high recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Specifically, the present invention provides a method for preparing cannabidiol crystals, characterized in that the method comprises the following steps:

[0024] (1) Extracting the industrial hemp powder with a first solvent, concentrating the extract containing cannabidiol obtained after extraction, to obtain a concentrated extract;

[0025] (2) dissolving the concentrated extract with an aqueous alkaline solution for saponification;

[0026] (3) adding a second solvent to the mixture of step (2) for the first extraction, adding a third solvent to the lower aqueous phase for the second extraction, concentrating the upper extract obtained from the second extraction to obtain a refined product;

[0027] (4) dissolving the refined product with a fourth solvent, performing chromatographic purification, and concentrating the eluent containing cannabidiol to obtain cannabidiol oil;

[0028] (5) Mixing the cannabidiol oil with a crystallization solvent for crystallization t...

Embodiment 1

[0067] Weigh 200 g of industrial hemp flower leaf powder with a particle size of 40 mesh, use 6 times the amount of acetone to carry out stirring extraction at 25° C. (normal temperature) for 2 hours, and extract 3 times. The acetone extract was concentrated to obtain 6.51 g of concentrated extract extract. The analysis results showed that the CBDV content was 6.67%, and the extraction rate was 98.69%.

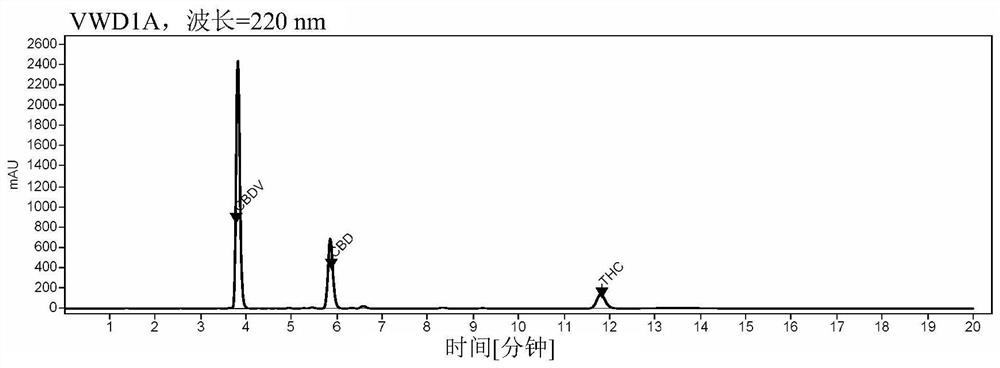

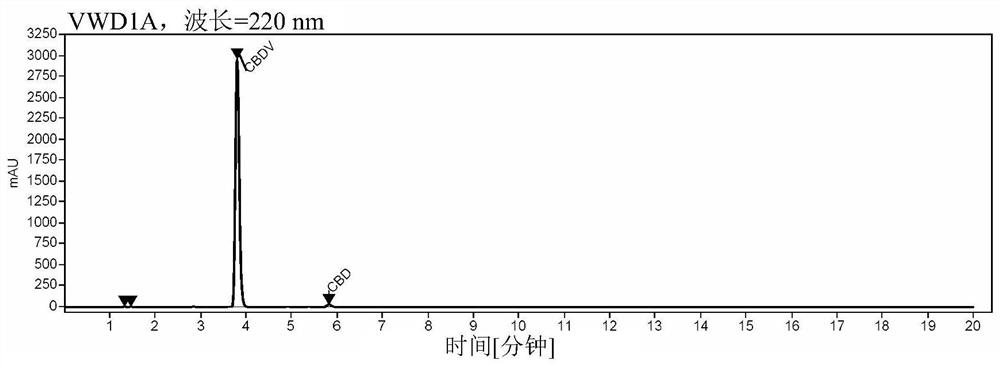

[0068] The obtained cannabidiol extract extract (6.51 g) was dissolved in 65 mL of 1% aqueous sodium hydroxide solution, and kept at a constant temperature of 80° C. for 3 hours. Add 65mL of n-hexane:petroleum ether=1:2 mixture for extraction, concentrate the extract to recover the organic solvent, and remove the upper organic phase containing some other cannabinoids and impurities. 65 mL of ethyl acetate was added to the water layer for extraction, and the upper layer extract was concentrated to obtain 2.5 g of subcannabinoid refined product. Analysis of crystallization sho...

Embodiment 2

[0073] Weigh 2000 g of industrial hemp flower leaf powder with a particle size of 40 mesh, use 6 times the amount of acetone to carry out stirring extraction at 25° C. (normal temperature) for 2 hours, and extract 3 times. The acetone extract was concentrated to obtain 66.32 g of concentrated extract extract. The analysis results showed that the CBDV content was 6.51%, and the extraction rate was 98.12%.

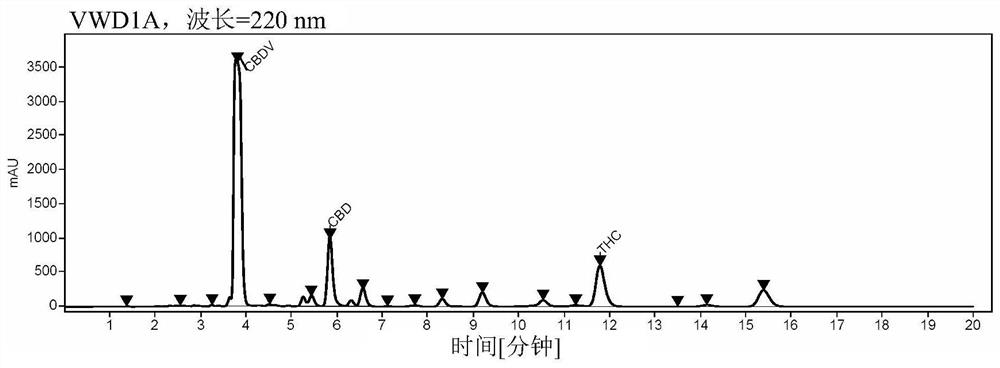

[0074] The obtained cannabidiol extract extract (66.32g) was dissolved in 663mL of 1% aqueous sodium hydroxide solution, and kept at a constant temperature of 80°C for 3h. Add 663 mL of n-hexane:petroleum ether=1:2 mixture for extraction, concentrate the extract to recover the organic solvent, and remove the upper organic phase containing some other cannabinoids and impurities. 663 mL of ethyl acetate was added to the water layer for extraction, and the upper layer extract was concentrated to obtain 24.6 g of subcannabinoid refined product. Analysis of the crystals showed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com