Preparation and ultraviolet protection application of artificial fungus melanin material

A technology of melanin and melanin precursor, which is applied in the field of melanin materials, can solve the problems of uneven morphology of fungal melanin materials, unfavorable large-scale use, complex enzyme production process, etc., achieve good UV absorption ability, facilitate recycling, and reduce costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of artificial fungal melanin nanoparticles, comprising the following steps:

[0052] Under air atmosphere, dissolve 150 mg of melanin precursor 1,8-dihydroxynaphthalene in a solvent of acetonitrile and water, including 15 mL of acetonitrile and 135 mL of deionized water, adjust the pH value to 3-4 with dilute hydrochloric acid, and stir for about 10 A solution was obtained in 1 minute. At this time, the concentration of 1,8-dihydroxynaphthalene was about 1 mg / mL.

[0053] Dissolve copper compound catalyst copper sulfate pentahydrate in water to prepare 1mol / L B solution.

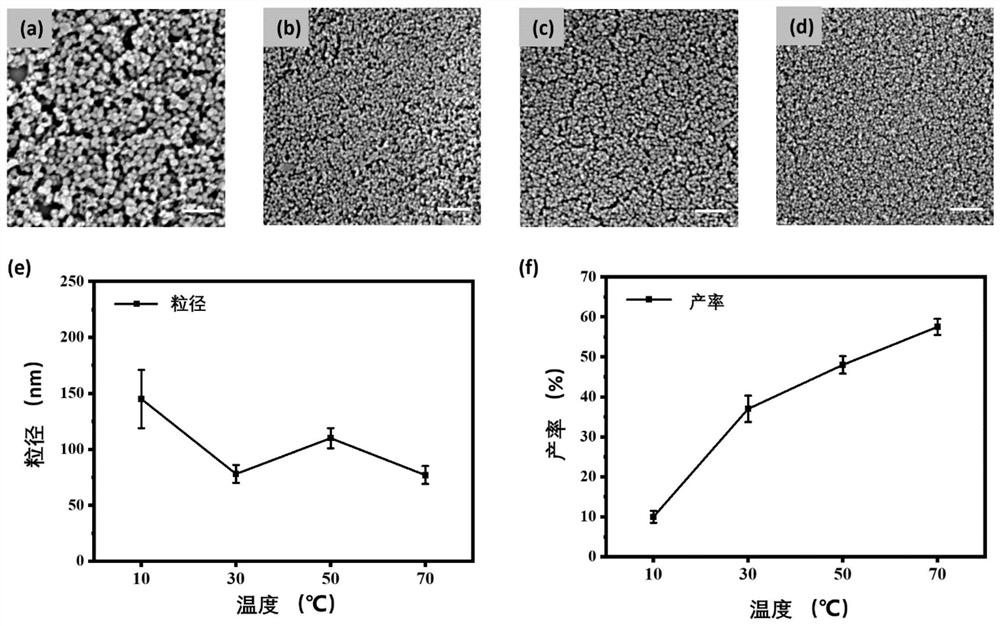

[0054] Heat solution A on a metal bath to 50°C under stirring, add 75 μL of solution B into A under stirring, and mix well. hours to obtain a reaction solution.

[0055] The reaction solution was centrifuged in a centrifuge at a speed of 12,000 rpm for 5 minutes, the precipitate was washed with deionized water, ultrasonically dispersed, and then centrifuged again, and repeated t...

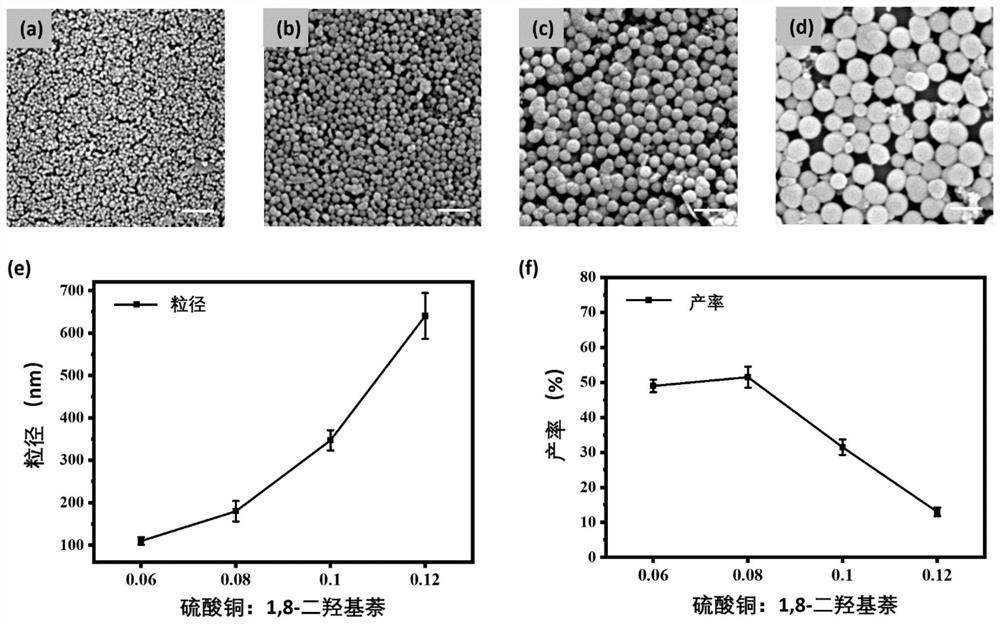

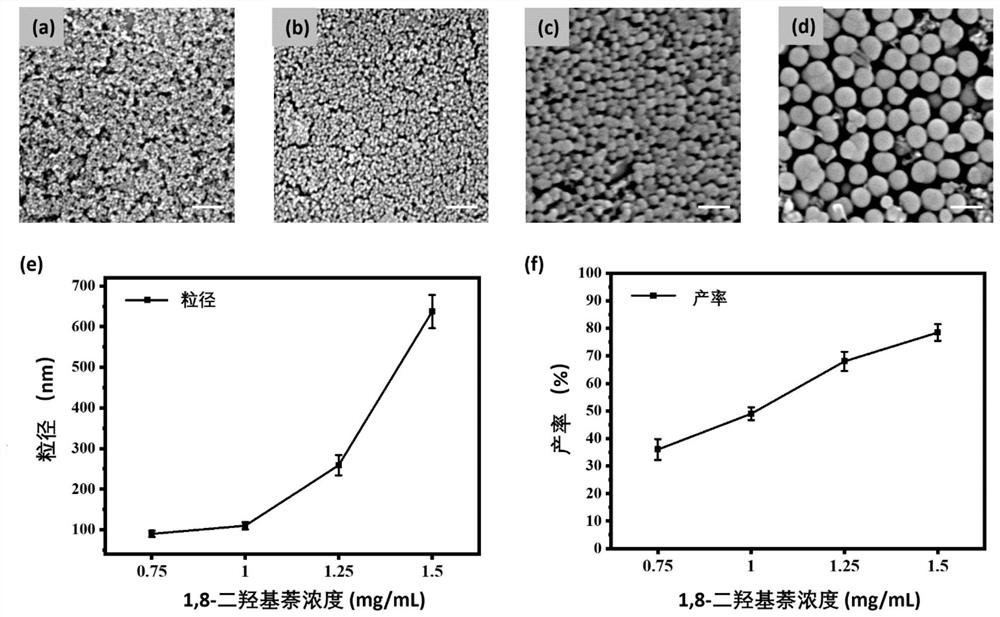

Embodiment 2 to Embodiment 10

[0058] Embodiment 2 to embodiment 10 are basically the same as embodiment 1, the difference lies in the ratio of 1,8-dihydroxynaphthalene and copper sulfate, as well as temperature and reaction time, see the following table for details.

[0059]

Embodiment 11 to Embodiment 12

[0061] Copper ions play a catalytic role in soluble copper salts, and its acid radical ions have little effect on the reaction. Most soluble copper salts have similar effects, and some insoluble copper compounds can also achieve similar effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com