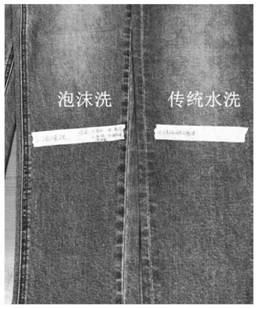

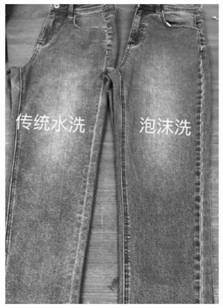

Foam washing method for denim fabric

A denim fabric and foam technology, applied in the field of foam washing of denim fabric, can solve the problems of serious pollution and increased water consumption, achieve uniform color, reduce water consumption, and facilitate the control of rinsing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Large machine 200 pieces

[0040] (1) Desizing and fermentation: put the jeans to be treated (200 pieces, about 120kg) in the washing machine, and then add 1kg of liquid neutral enzyme ATB710, 1kg of foaming agent EASYFOAM, and high elastic anti-staining agent FORTRES TLEX Mix 0.6kg and 200kg of normal temperature water into the foam machine and beat it into foam, then output it into the washing machine, run the machine for 45 minutes, compare it with the sample (board comparison) and reach the required flower degree;

[0041] (2) Rinsing: Mix 5kg of bleaching water, 1kg of foaming agent EASYFOAM, 0.5kg of high-elastic anti-stain agent FORTRES TLEX and 50kg of normal temperature water into the foam machine, beat it into foam, and then output it into the washing machine. Run the machine for 15 minutes, rinse After the plate reaches the desired color depth, water is released;

[0042] (3) Clean water: inject 800kg of clean water at room temperature into the ...

Embodiment 2

[0048] Embodiment 2 Large machine 200 pieces

[0049] (1) Desizing and fermentation: put the jeans to be treated (200 pieces, about 110kg) in the washing machine, and then add 1kg of liquid neutral enzyme ATB710, 1kg of foaming agent EASYFOAM, and high elastic anti-staining agent FORTRES TLEX Mix 0.6kg and 200kg of normal temperature water into the foam machine and beat it into foam, then output it into the washing machine, run the machine for 40 minutes, compare it with the sample (board comparison) and reach the required flower degree;

[0050](2) Rinsing: Mix 5kg of bleaching water, 1kg of foaming agent EASYFOAM, 0.5kg of high-elastic anti-staining agent FORTRES TLEX and 50kg of normal temperature water into the foam machine, beat it into foam, and then output it into the washing machine. Run the machine for 12 minutes. After rinsing When the board reaches the desired color depth, drain the water;

[0051] (3) Clean water: pour 800kg of clean water at room temperature into...

Embodiment 3

[0057] Embodiment 3 200 large machines

[0058] (1) Desizing and yeast grinding: put the jeans to be treated (200 pieces, about 115kg) in the washing machine, and then add 1kg of liquid neutral enzyme ATB710, 1kg of foaming agent EASYFOAM, and high elastic anti-staining agent FORTRES TLEX Mix 0.6kg and 200kg of normal temperature water into the foam machine and beat it into foam, then output it into the washing machine, run the machine for 50 minutes, compare it with the sample (board comparison) and reach the required flower degree;

[0059] (2) Rinsing: Mix 5kg of bleaching water, 1kg of foaming agent EASYFOAM, 0.5kg of high-elastic anti-dyeing agent FORTRES TLEX and 50kg of normal temperature water into the foam machine, beat it into foam, and then output it into the washing machine. Run the machine for 18 minutes. After rinsing When the board reaches the desired color depth, drain the water;

[0060] (3) Clean water: inject 800kg of clean water at room temperature into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com