Light skin-friendly fabric and preparation method thereof

A skin-friendly, fabric technology, applied in the field of textile fabrics, can solve problems such as decreased comfort and lack of hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

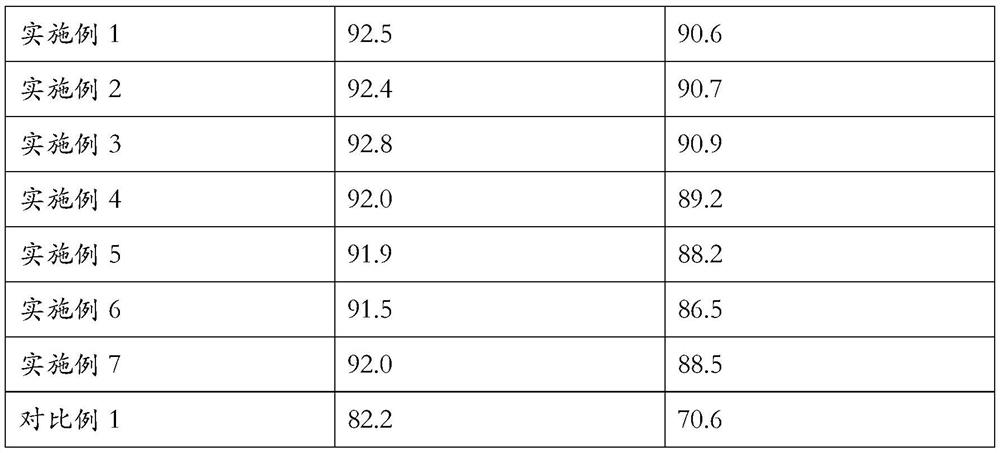

Examples

Embodiment 1

[0039] Soak the cotton fabric in water, then add 0.3% cotton fabric mass compound enzyme to the water, at a temperature of 32°C and an ultrasonic frequency of 55kHz, after constant temperature ultrasonic enzymolysis for 3 hours, take out the cotton fabric and rinse it with deionized water 4 times, and then dry the rinsed cotton fabric to a constant weight at a temperature of 55°C to obtain a dewaxed cotton fabric; the compound enzyme is prepared by mixing pectinase, amylase, protease and PVA degrading enzyme. become;

[0040] Soak the dewaxed cotton fabric in a sodium periodate solution with a mass fraction of 3%, at a temperature of 75°C and an ultrasonic frequency of 60kHz, keep warm for 3 hours after ultrasonic oxidation reaction, wash with water, and dry to obtain an oxidized cotton fabric;

[0041] Mix collagen and water at a mass ratio of 1:10, keep warm and swell for 48 hours at a temperature of 45°C, then add collagenase with 1% of the amount of collagen, adjust the pH...

Embodiment 2

[0046] Soak the cotton fabric in water, then add 0.4% of the cotton fabric’s weight compound enzyme to the water, and at a temperature of 33°C and an ultrasonic frequency of 60kHz, perform ultrasonic enzymolysis at a constant temperature for 4 hours, then take out the cotton fabric and rinse it with deionized water 5 times, and then dry the rinsed cotton fabric to a constant weight at a temperature of 58°C to obtain a dewaxed cotton fabric; the compound enzyme is prepared by mixing pectinase, amylase, protease and PVA degrading enzyme. become;

[0047] Soak the dewaxed cotton fabric in a sodium periodate solution with a mass fraction of 4%, at a temperature of 78°C and an ultrasonic frequency of 70kHz, keep warm for 4 hours after ultrasonic oxidation reaction, wash with water, and dry to obtain an oxidized cotton fabric;

[0048] Mix collagen and water at a mass ratio of 1:15, keep warm and swell for 52 hours at a temperature of 50°C, then add collagenase with 2% of the amount...

Embodiment 3

[0053] Soak the cotton fabric in water, then add 0.5% cotton fabric mass complex enzyme to the water, at a temperature of 35°C and an ultrasonic frequency of 65kHz, after constant temperature ultrasonic enzymolysis for 5 hours, take out the cotton fabric and rinse it with deionized water 6 times, and then dry the rinsed cotton fabric to a constant weight at a temperature of 65°C to obtain a dewaxed cotton fabric; the compound enzyme is produced by mixing pectinase, amylase, protease and PVA degrading enzyme. become;

[0054] Soak the dewaxed cotton fabric in a sodium periodate solution with a mass fraction of 5%, at a temperature of 80°C and an ultrasonic frequency of 80kHz, keep warm for 5 hours after ultrasonic oxidation reaction, wash with water, and dry to obtain an oxidized cotton fabric;

[0055] Mix collagen and water at a mass ratio of 1:20, keep warm and swell for 56 hours at a temperature of 55°C, then add collagenase with 3% collagen content, adjust the pH to 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com