Deepwater steep fluctuating rock surface steel cofferdam construction process

A construction technique, steel cofferdam technology, applied in foundation structure engineering, erection/assembly of bridges, sheet pile walls, etc., can solve the problem of inability to ensure that the stiffening steel is located inside the steel cofferdam, difficulty in positioning of occlusal pile drilling, and anti-penetration Discounts and other issues, to achieve the effect of reducing construction risk, shortening construction period, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

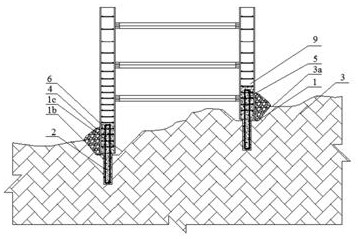

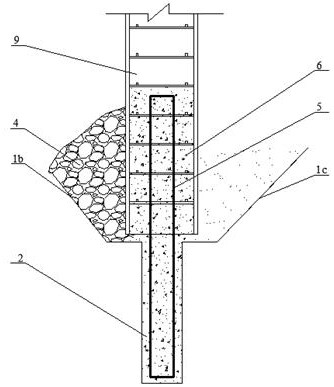

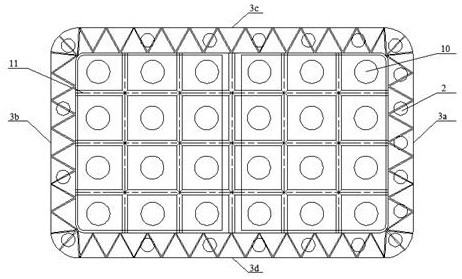

[0031] When large-scale steel cofferdams are applied to deep-water steep and uncovered rock surfaces in the construction of deep-water bridge projects, due to the steep trend of the rock surface surface, the location of the cofferdam sinking is not accurate, and the existing large-scale steel cofferdams have problems The large amount of rock blasting in the blasting construction process has a large adverse impact on environmental pollution, see figure 1 , 2 , 3, the present invention is mainly through the excavation of the foundation trench, which can ensure that the anti-overturning and anti-sliding capabilities of the steel cofferdam under adverse loads such as gravity and river water impact can meet the requirements, and the bottom of the cofferdam can be integrated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com