Manufacturing method of pressure casting product with alloy lining or inner container

A production method and alloy technology, which is applied in the field of production of pressure casting products equipped with alloy liners or liners, can solve problems affecting the quality of pressure casting products, sand core collapse, etc., to avoid and deformation, avoid collapse, improve The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

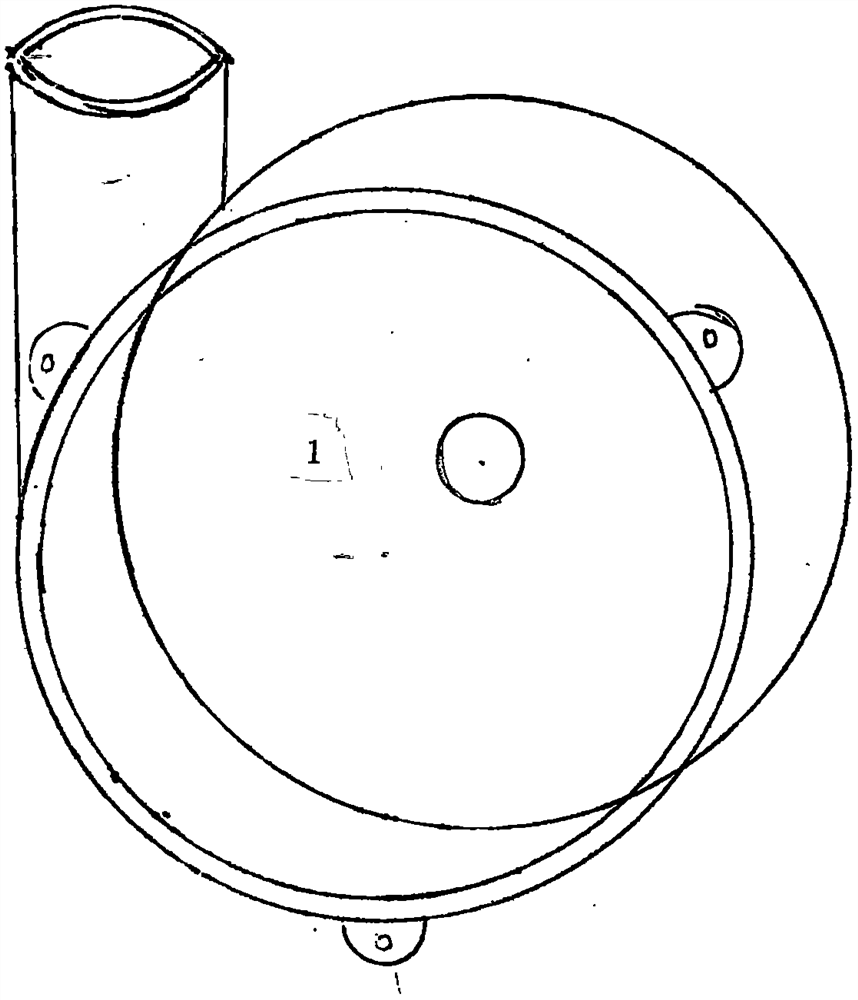

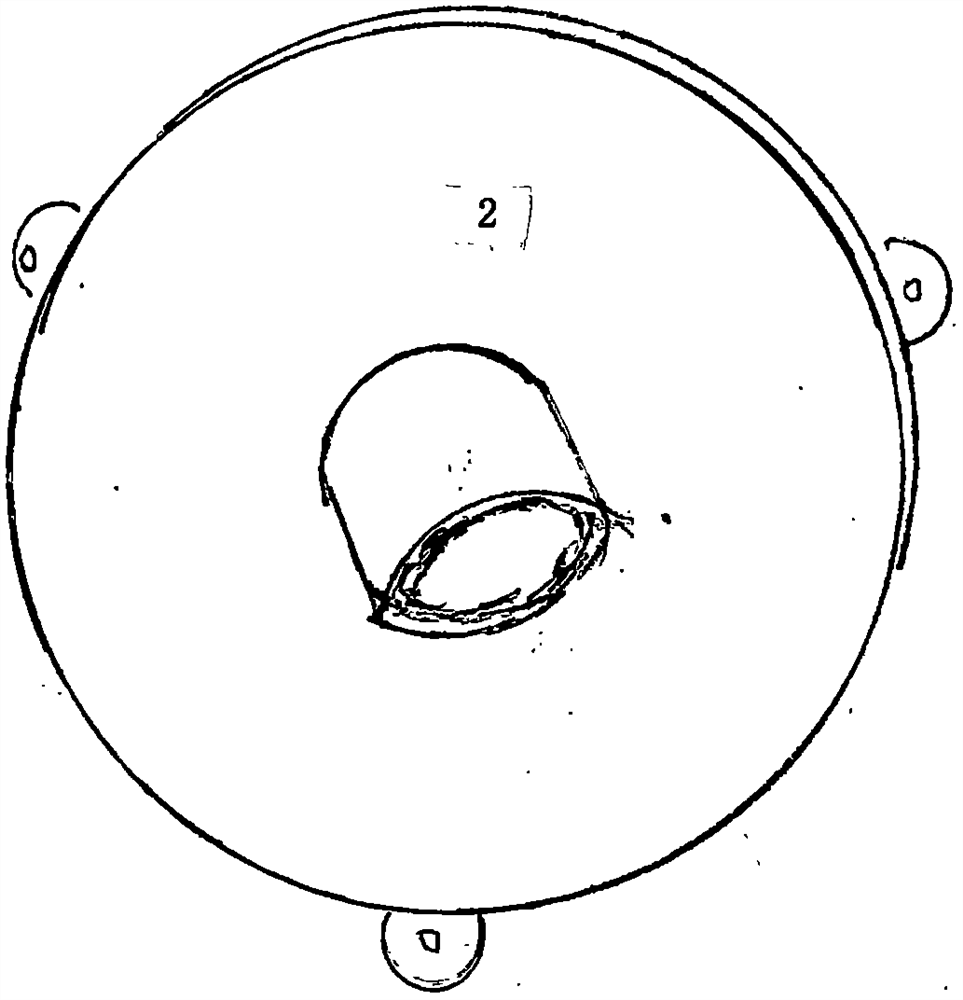

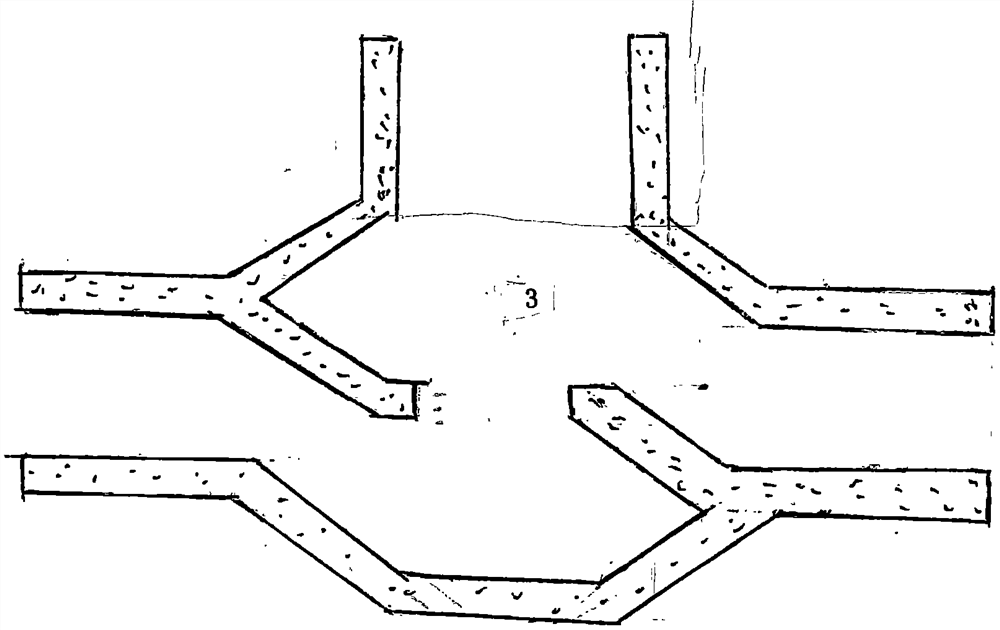

[0013] figure 1 and figure 2 Shown, a kind of manufacturing method of the pressure casting product that alloy liner is housed. The centrifugal pump casing mold with alloy lining is a hollow composite mold. The centrifugal pump casing hollow composite mold is composed of a centrifugal pump casing hollow sub-mold. The centrifugal pump casing hollow sub-mold is made of steel plate stamping and welding. It is stamped and welded with stainless steel plate, brass plate or aluminum alloy plate. Melt steel slag powder or glass powder with an oxyacetylene flame and spray it on the inner surface of the hollow sub-mold of the centrifugal pump casing that is in contact with molten steel during pressure casting, or use 'water glass' to blend steel slag powder or glass powder, and then coat it on the mold during pressure casting The inner surface of the hollow sub-mold of the centrifugal pump casing in contact with the molten steel, and then heated and melted with oxyacetylene flame to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com