c 2 n/porous graphene composite material, preparation method thereof, and diaphragm comprising the same

A technology of porous graphene and composite materials, applied in the field of lithium-sulfur batteries, can solve the problems of poor cycle performance, inability to effectively suppress the shuttle effect, low energy density of lithium-sulfur batteries, etc. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

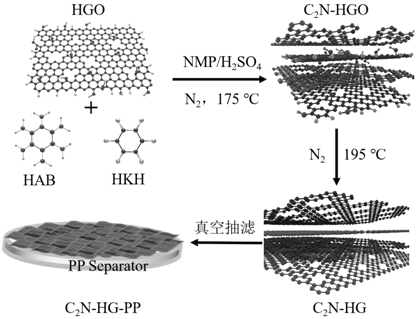

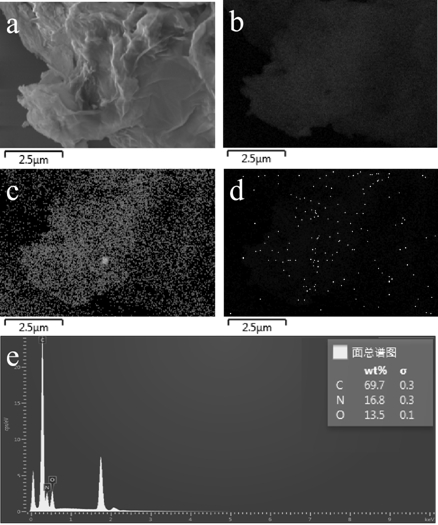

[0043] Example 1 Preparation C 2 N / porous graphene composites

[0044] In the first step, graphene oxide was oxidized by hydrogen peroxide to form pores, and 5 mL of 30% hydrogen peroxide (H 2 o 2 ) solution was dropped into 50 mL graphene oxide (GO) aqueous solution (2 mg / mL), then heated at 95 °C for 4 h with continuous stirring, cooled to room temperature, and the product was collected by centrifugation at a speed of 10000 r / min , washed with deionized water to remove residual H 2 o 2 , and finally redispersed in deionized water to obtain a 2 mg / mL porous graphene oxide (HGO) suspension, and then freeze-dried to obtain a porous graphene oxide (HGO) aerogel.

[0045] In the second step, 100 mg of HGO was weighed, added to 100 mL of deoxygenated NMP for ultrasonic dispersion for 4 h, poured into a three-necked flask under a nitrogen atmosphere, and placed in an ice-water bath. 300 mg of hexaaminobenzene (HAB) was dissolved in 30 mL of deoxygenated N-methylpyrrolidone (NM...

Embodiment 2

[0048] Example 2 Preparation of diaphragm

[0049] With the C that embodiment 1 makes 2 N-HG was ultrasonically dispersed in ethanol solution, ultrasonicated for 1 h, and prepared into a uniform dispersion with a concentration of 0.1 mg / mL. Using a glass sand core funnel, the C 2 N-HG was suction-filtered on a PP membrane, then dried naturally, and then dried under reduced pressure at room temperature to obtain single-sided modified C 2 N / porous graphene modified PP separator, C 2 The loading capacity of N / porous graphene is 0.05mg / cm 2 , denoted as C 2 N-HG-P-0.05.

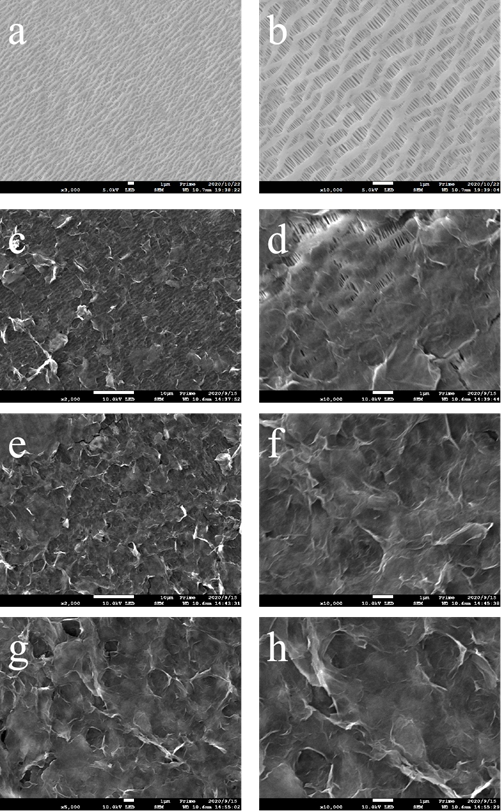

[0050] C prepared in this example 2 See the SEM picture of N-HG-PP-0.05 image 3 .

[0051] Adopt the C that this embodiment makes 2 The performance diagram of the lithium-sulfur battery made of N-HG-PP-0.05 separator cycled at 1 C rate for 300 cycles is shown in Figure 4 .

Embodiment 3

[0053] The same as the method of Example 2, the difference is that the obtained single-sided modified C 2 C in N / porous graphene modified PP separator 2 The loading of N / porous graphene is 0.1 mg / cm 2 , denoted as C 2 N-HG-P-0.1.

[0054] C prepared in this example 2 See the SEM picture of N-HG-PP-0.1 image 3 .

[0055] Adopt the C that this embodiment makes 2 The performance diagram of the lithium-sulfur battery made of N-HG-PP-0.1 separator at 1 C rate for 300 cycles is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com