A preparation method of graphene oxide/alpha-fetoprotein aptamer electrochemical sensor

An alpha-fetoprotein and graphene technology, applied in scientific instruments, instruments, material analysis by electromagnetic means, etc., can solve the problems of being susceptible to external interference, loss of labeled antibodies, long analysis time, etc., to overcome poor stability. , the effect of increasing the amount of modification and simplifying the analysis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

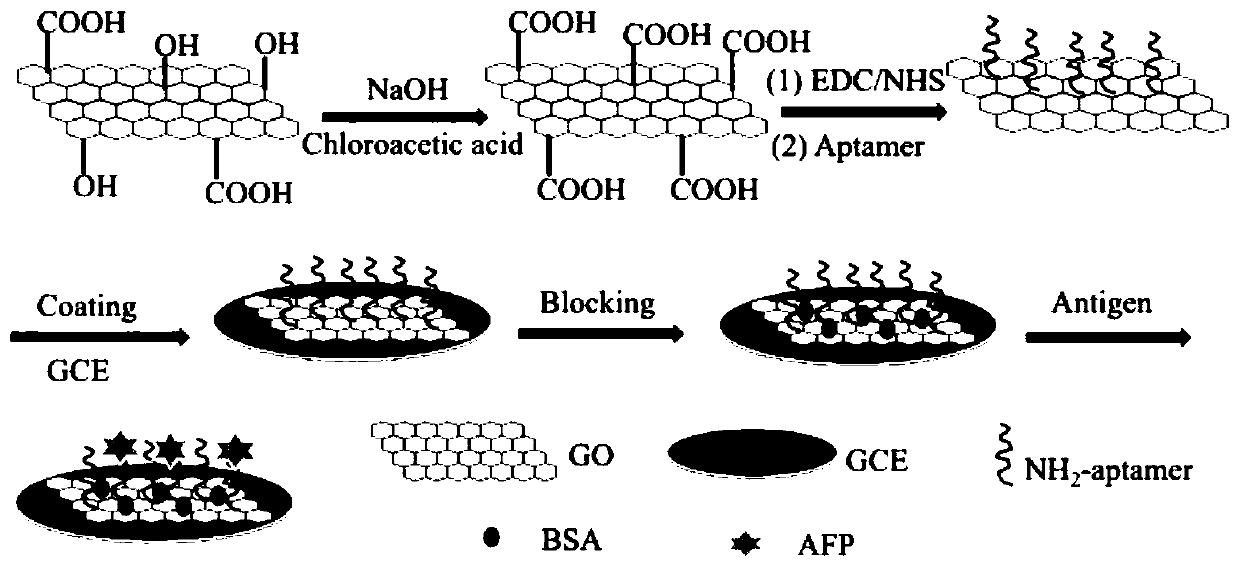

[0031] It has been found through experiments that different process parameters have a certain influence on the obtained graphene oxide / alpha-fetoprotein aptamer complex. From the perspective of improving detection sensitivity, the present invention obtains a A preparation method of graphene oxide / alpha-fetoprotein aptamer complex, through which a sufficient amount of aminated alpha-fetoprotein is grafted onto carboxylated graphene oxide to maximize the sensitivity of the electrochemical sensor. The preparation method comprises the following steps:

[0032] (1) ultrasonically disperse 2 to 6 mg of graphene oxide in 1 to 3 ml of deionized water for 1 to 1.5 hours to obtain a uniformly dispersed graphene oxide suspoemulsion;

[0033] (2) adding 0.3~0.6g NaOH and 0.2~0.5g chloroacetic acid to the obtained graphene oxide suspoemulsion, and ultrasonic treatment for 10~12h, to increase the carboxyl groups on the graphene oxide;

[0034] (3) After centrifuging and washing the carboxy...

Embodiment 1

[0057] The preparation method of graphene oxide / alpha-fetoprotein aptamer complex comprises the following steps:

[0058] (1) Ultrasonic disperse 2 mg of graphene oxide in 1 ml of deionized water for 1 h to obtain a uniformly dispersed graphene oxide suspoemulsion.

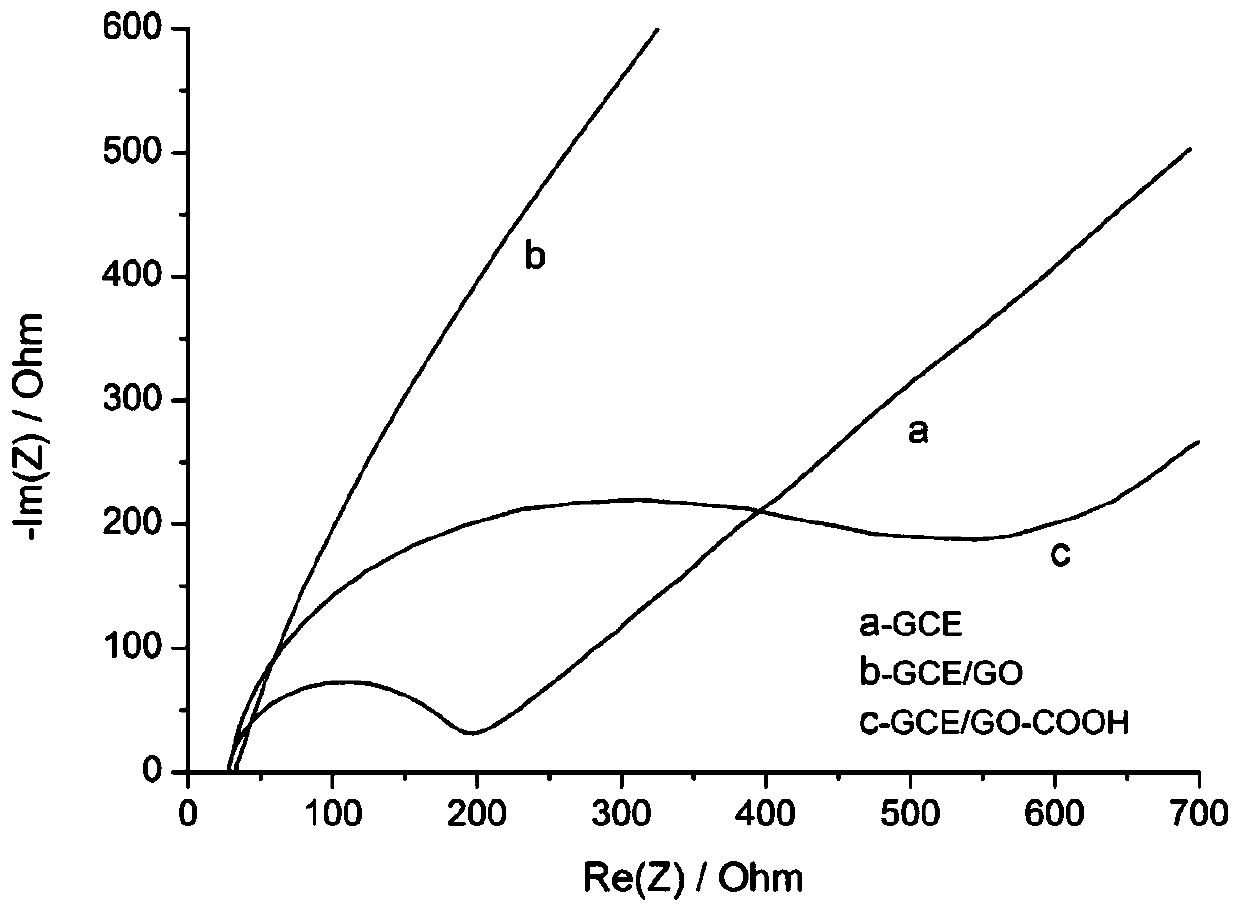

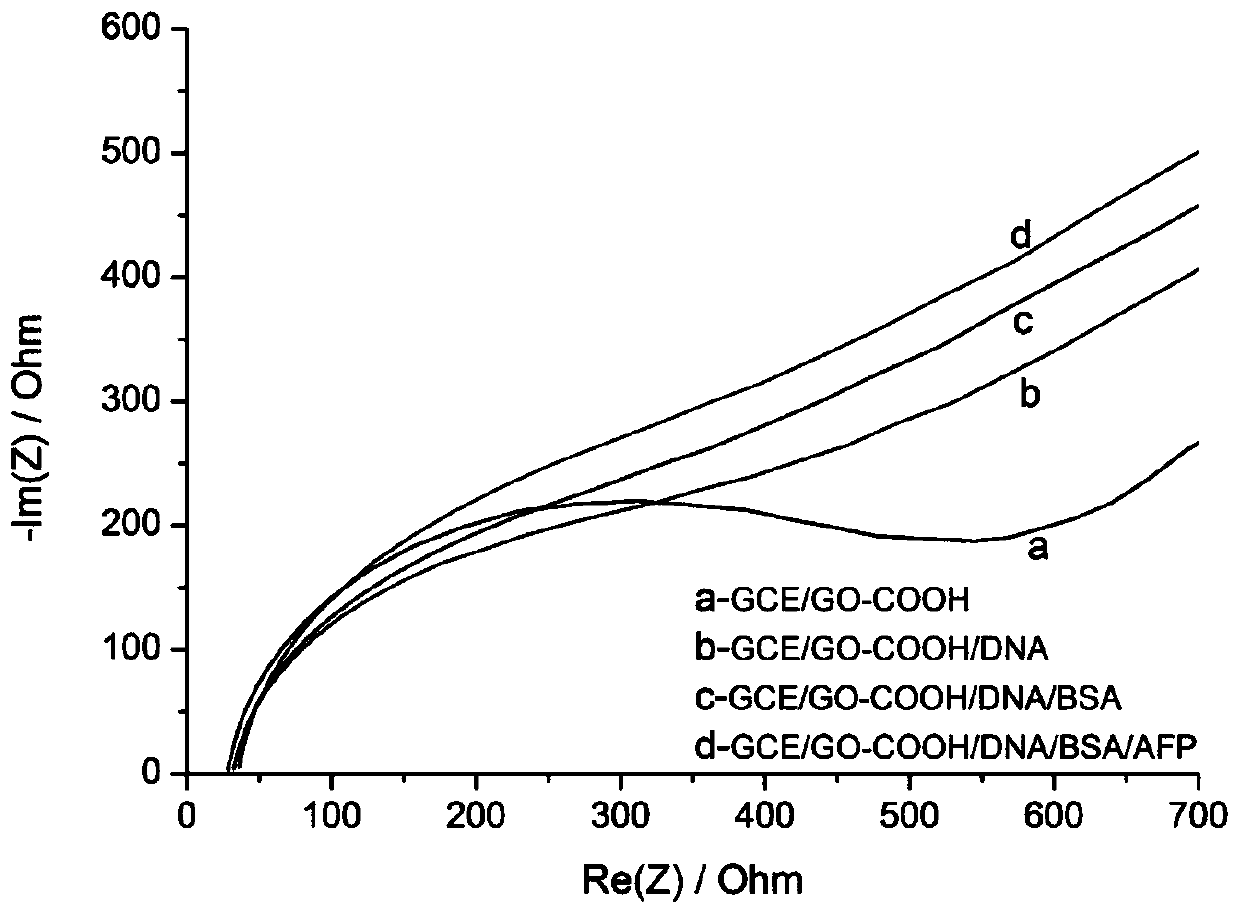

[0059] (2) Add 0.3g NaOH and 0.2g chloroacetic acid to the above graphene oxide suspoemulsion, and ultrasonically treat it for 12h to increase the carboxyl groups on the graphene oxide. Such as figure 2 As shown, graphene oxide has a large change in its corresponding impedance spectrum before and after carboxylation treatment, indicating that the carboxyl functional group content on the surface of graphene oxide after carboxylation increases.

[0060] (3) The carboxylated graphene oxide was washed by centrifugation, then 1.5ml of 0.3M EDC and 1ml of 0.2M NHS were added, and ultrasonic treatment was performed for 1h to activate the carboxyl groups on the graphene oxide.

[0061] (4) After centrifuging and washin...

Embodiment 2

[0064] The preparation method of graphene oxide / alpha-fetoprotein aptamer complex comprises the following steps:

[0065] (1) Ultrasonic disperse 4 mg of graphene oxide in 1.5 ml of deionized water for 1 hour to obtain a uniformly dispersed graphene oxide suspoemulsion.

[0066] (2) Add 0.4g NaOH and 0.3g chloroacetic acid to the above-mentioned graphene oxide suspoemulsion, and ultrasonically treat it for 12h to increase the carboxyl groups on the graphene oxide.

[0067] (3) The carboxylated graphene oxide was washed by centrifugation, then 3ml of 0.3M EDC and 2ml of 0.2M NHS were added, and ultrasonic treatment was performed for 1h to activate the carboxyl groups on the graphene oxide.

[0068] (4) After centrifuging and washing the activated graphene oxide, add 0.75 ml of aminated alpha-fetoprotein aptamer solution (prepared with Tris-EDTA solution) with a concentration of 200 μg / ml and incubate for 30 min to bind the alpha-fetoprotein aptamer chain grafted onto the graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com