Method for removing phenylurea herbicide chlortoluron in water

A herbicide and water removal technology, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of no continuous sterilization ability and microbial content recovery, and saves economic costs and time costs. Free radical consumption, simple and safe application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

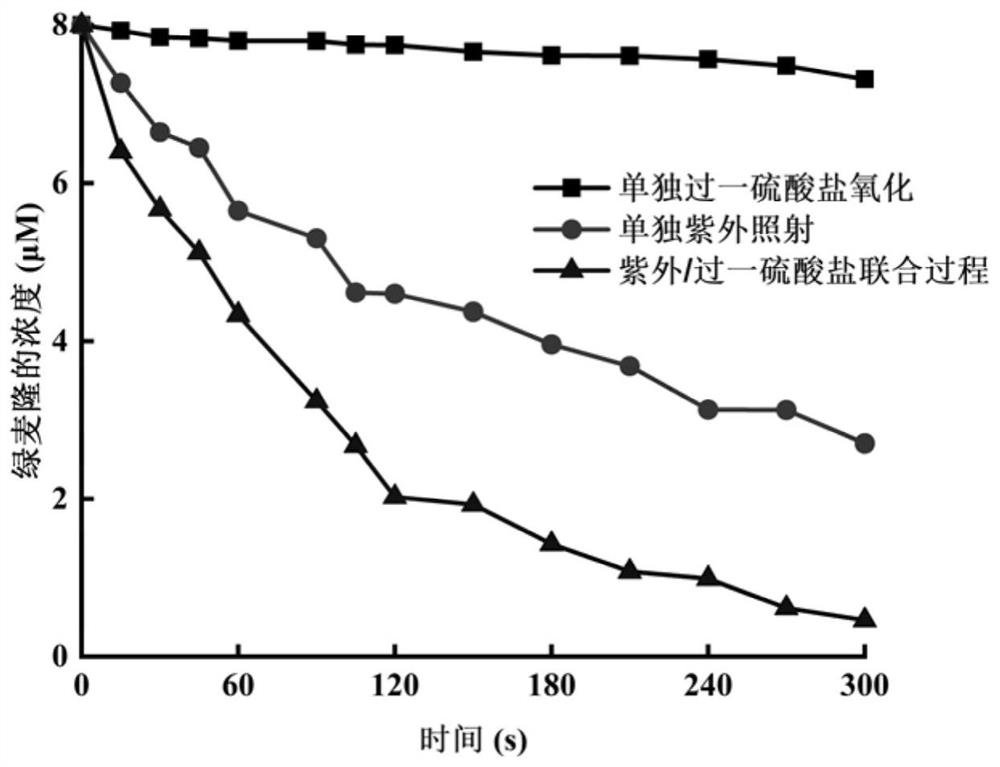

[0039] The initial concentration of chlorotoluron was prepared with ultrapure water as 8 μM, and the degradation experiments of chlorotoluron were carried out under the three processes respectively. The degradation experiment operation of chlorotoluron under the single persulfuric acid oxidation process is as follows: using NaOH and H at a concentration of 1M 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add peroxysulfate to the chlorotoluron solution to make the concentration reach 160 μM, and control the reaction temperature to 25°C; 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, irradiate the chlorotoluron solution with ultraviolet light, and control the ultraviolet irradiation intensity to 2.43mW / cm 2 , the reaction temperature is controlled at 25°C; the degradation experiment operation of chlorotoluron under the UV / peroxymonosulfuric acid combined process is as follows: use 1M NaOH and H 2 SO 4 Adjust the initial pH of the chloroto...

Embodiment 2

[0042] A method for removing the phenylurea herbicide chlorotoluron in water by a combination process of ultraviolet / permonosulfate, comprising the following steps:

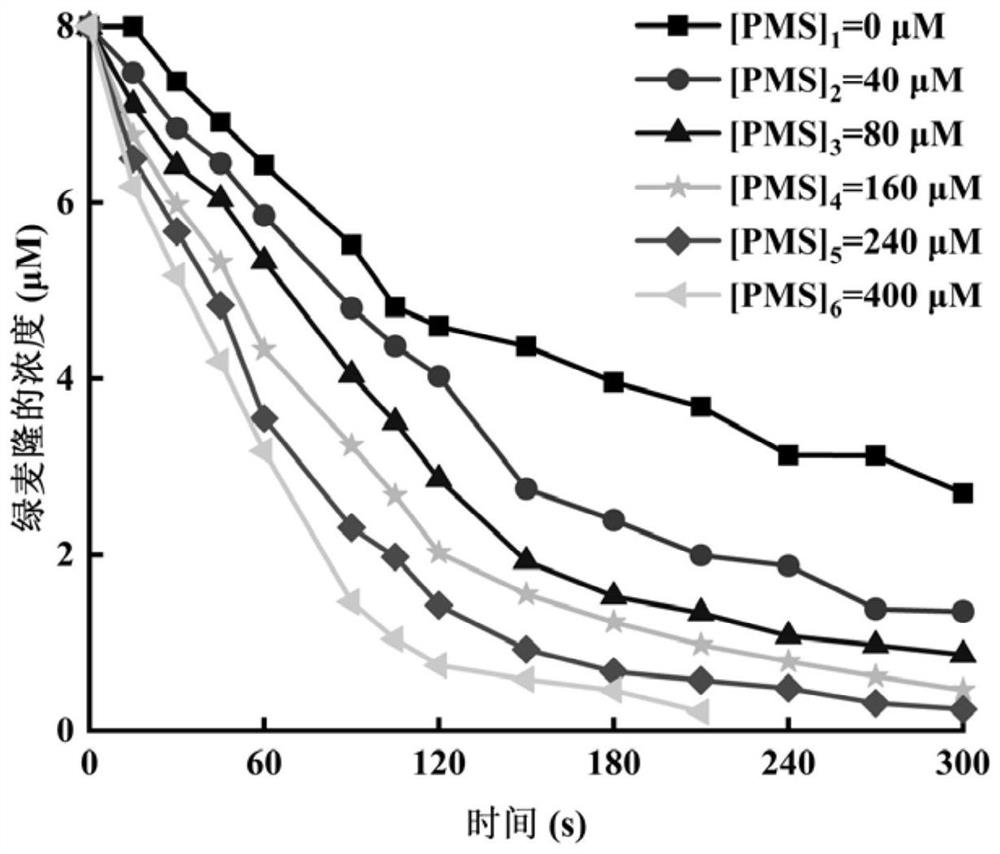

[0043] Use ultrapure water to prepare the initial concentration of chlortoluron as 8 μM, and use 1M NaOH and H 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add persulfate solution to the chlorotoluron solution, control the initial addition of monosulfuric acid so that the concentrations are 0, 40, 80, 160, 240 and 400 μM, and simultaneously carry out ultraviolet Irradiation, control the UV intensity to 2.43mW / cm 2 , after 300s of reaction, the removal rate of chlorotoluron is detailed in figure 2 .

[0044] From figure 2 It can be seen that increasing the dosage of peroxymonosulfate can accelerate the degradation rate of chlorotoluron. When the concentration of persulfate increased from 40 μM to 400 μM, the degradation rate of chlorotoluron increased from 83.1% to 100% after 300 seconds...

Embodiment 3

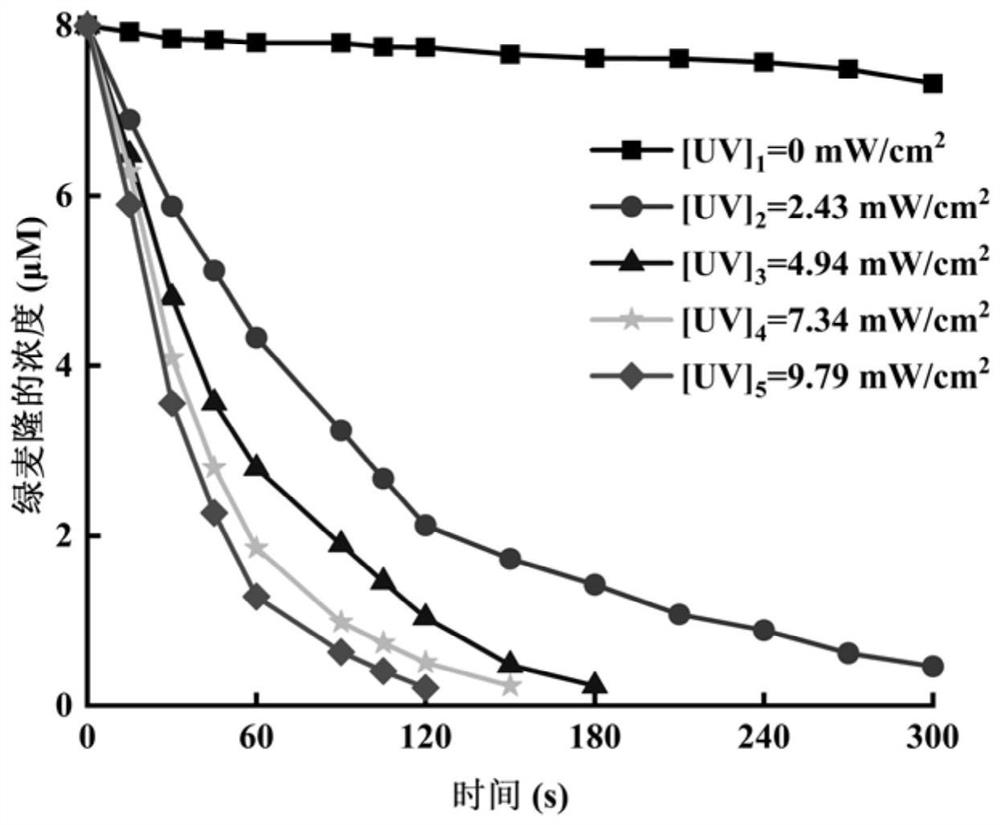

[0046] A method for removing the phenylurea herbicide chlorotoluron in water by a combination process of ultraviolet / permonosulfate, comprising the following steps:

[0047] Use ultrapure water to configure the initial concentration of chlortoluron to be 8 μM, and use 1M NaOH and H 2 SO 4 Adjust the initial pH of the chlorotoluron solution to 7, add peroxymonosulfate solution to the chlorotoluron solution to make the concentration 160 μM, and carry out ultraviolet irradiation at the same time, and control the ultraviolet intensity to be 2.43, 4.94, 7.34 and 9.79mW / cm respectively 2 , at a temperature of 25°C, the basic degradation times of chlorotoluron are 120s, 150s, 180s, and 300s, respectively.

[0048] From image 3 It can be seen that with the gradual increase of the intensity of ultraviolet light, the degradation rate of chlorotoluron gradually increased. When the intensity of ultraviolet light increases, the photon energy in the solution increases, and the SO produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com