Nozzle as well as preparation method and application thereof

A nozzle and yttrium oxide technology, which is applied in the field of refractory materials, can solve problems such as short service life, low production efficiency, and separation and reunion, and achieve the effects of alleviating thermal stress, reducing waste of resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

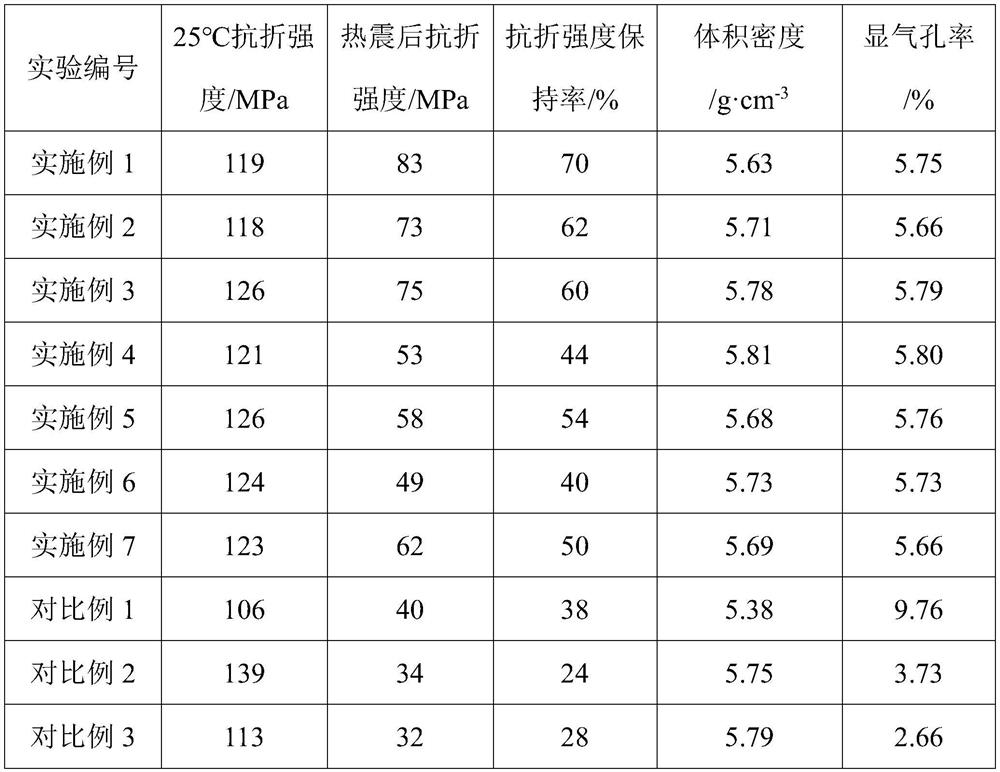

Examples

Embodiment 1

[0057] This embodiment provides a method for preparing a nozzle, the preparation method comprising the following steps:

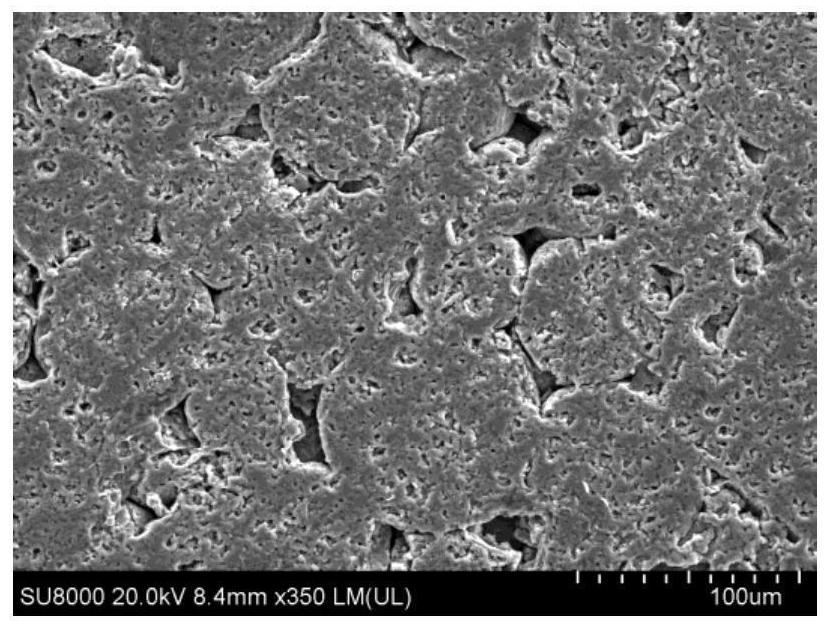

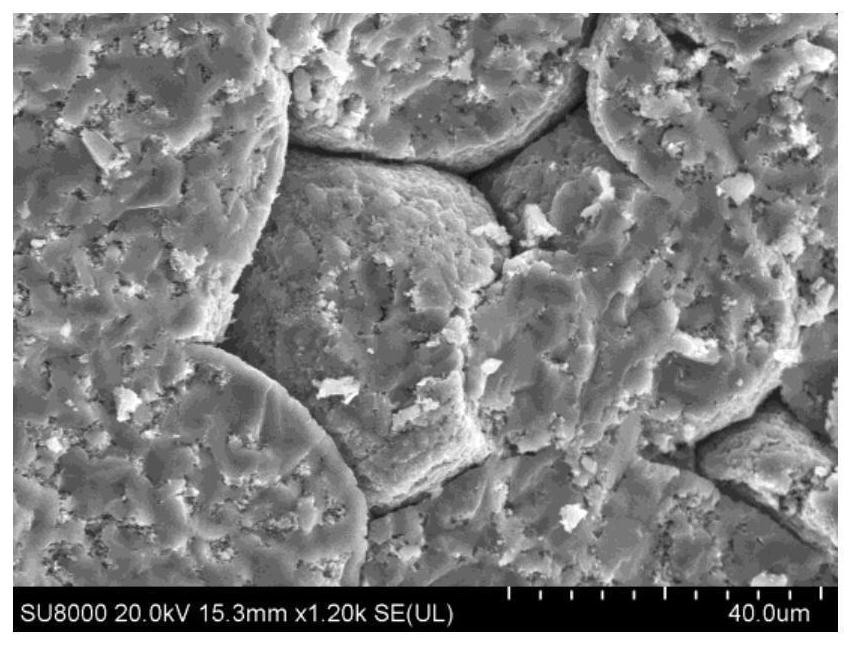

[0058] (1) Mix water-based epoxy resin (Shell, EP-815) with a particle size not exceeding 5 μm, D 90 Yttria-stabilized zirconia powder of 3.5 μm (scanning electron microscope picture see figure 1 ), spray granulation to obtain a particle size range of 34-88 μm, D 50 Spherical powder of 55 μm (scanning electron microscope picture see figure 2 ); the yttria-stabilized zirconia powder is obtained by crushing, magnetically separating, pickling and drying the zirconia-containing raw material; the zirconia-containing raw material is post-use waste of 3C products;

[0059] (2) mixing thermosetting phenolic resin (Leixiang Chemical Factory, Erqi District, Zhengzhou City, FQ-6) and the spherical powder obtained in step (1), under pressure molding at 250MPa, to obtain Huangpi;

[0060] (3) 120°C to dry the barley obtained in step (2), the drying time is 12h; then...

Embodiment 2

[0062] This embodiment provides a method for preparing a nozzle, the preparation method comprising the following steps:

[0063] (1) Mix water-based epoxy resin (Momentive / Hexion, 3520) with a particle size not exceeding 5 μm, D 90 Yttria-stabilized zirconia powder with a size of 3 μm, spray granulated to obtain a particle size range of 34-88 μm, D 50 It is a spherical powder of 60 μm; the yttria-stabilized zirconia powder is obtained from raw materials containing zirconia through crushing, magnetic separation, pickling and drying; the raw materials containing zirconia are post-use waste of medical devices;

[0064] (2) mixing thermosetting phenolic resin (Leixiang Chemical Factory, Erqi District, Zhengzhou City, FQ-6) and the spherical powder obtained in step (1), under pressure molding at 200MPa, to obtain Huangpi;

[0065] (3) 150°C to dry the barley obtained in step (2), the drying time is 10h; then raise the temperature to 1160°C at a rate of 1.8°C / min, then raise the te...

Embodiment 3

[0067] This embodiment provides a method for preparing a nozzle, the preparation method comprising the following steps:

[0068] (1) Mix water-based epoxy resin (Momentive / Hexion, 3520) with a particle size not exceeding 5 μm, D 90 Yttria-stabilized zirconia powder is 4μm, spray granulated, and the particle size range is 34-88μm, D 50 It is a spherical powder of 50 μm; the yttria-stabilized zirconia powder is obtained by crushing, magnetically separating, pickling and drying the zirconia-containing raw material; the zirconia-containing raw material is used waste of ceramic knives;

[0069] (2) mixing phenolic resin (Leixiang Chemical Factory, Erqi District, Zhengzhou City, FQ-6) with the spherical powder obtained in step (1), and molding under 300MPa pressure to obtain Huangpi;

[0070] (3) 100°C drying of the barley obtained in step (2), the drying time is 16h; then the temperature is raised to 1140°C at a rate of 2.2°C / min, and then the temperature is raised to 1210°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com