Preparation method of low-modulus alcohol-resistant water-based polyurethane resin for medical latex gloves

A technology for water-based polyurethane and latex gloves, applied in the field of water-based polymers, can solve the problems of water-based polyurethane resin pollution, injuries to medical staff in gloves, limited effect, etc., to improve water resistance, reduce the probability of bacterial growth, and achieve high resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

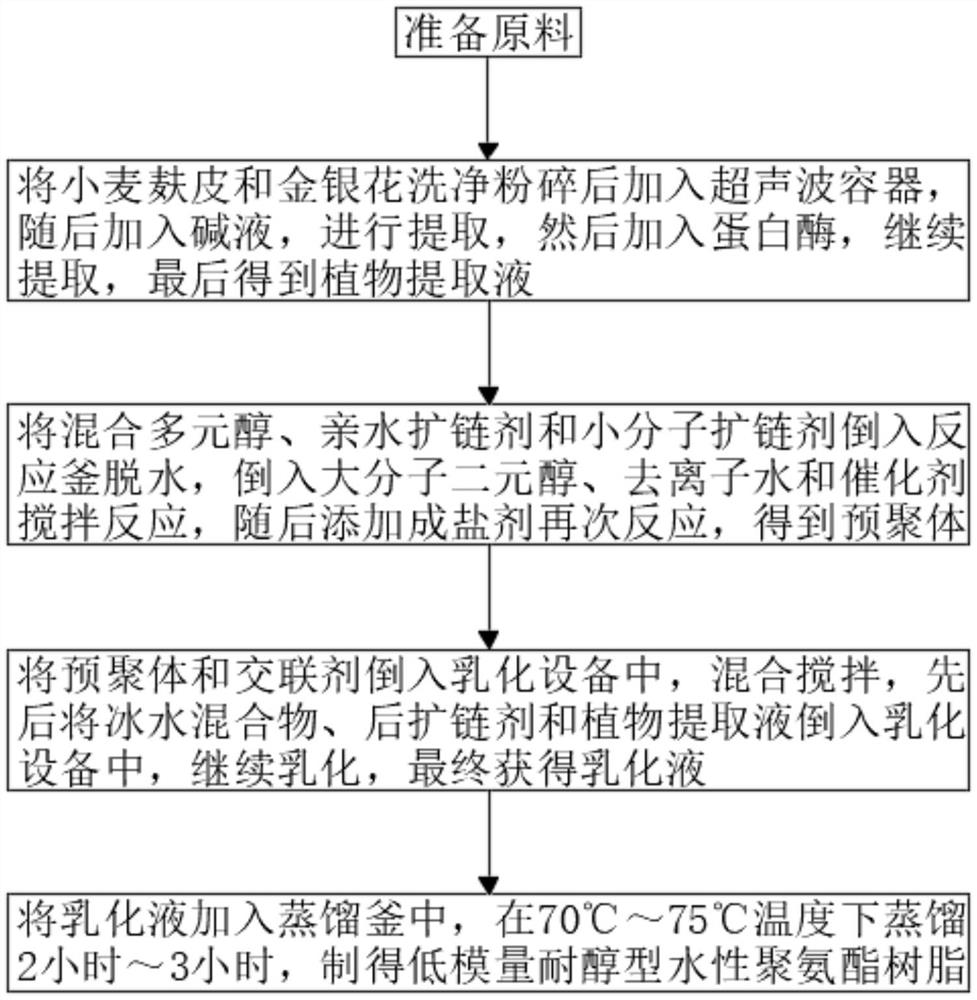

[0023] refer to figure 1 , embodiment one

[0024] The preparation method of low modulus alcohol-resistant type water-based polyurethane resin for medical latex gloves is proposed in the present embodiment, comprising the following steps:

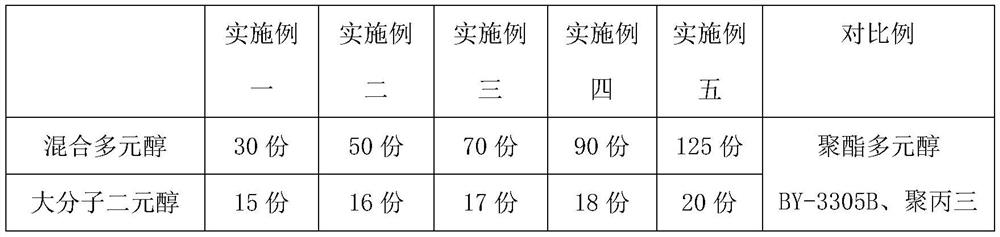

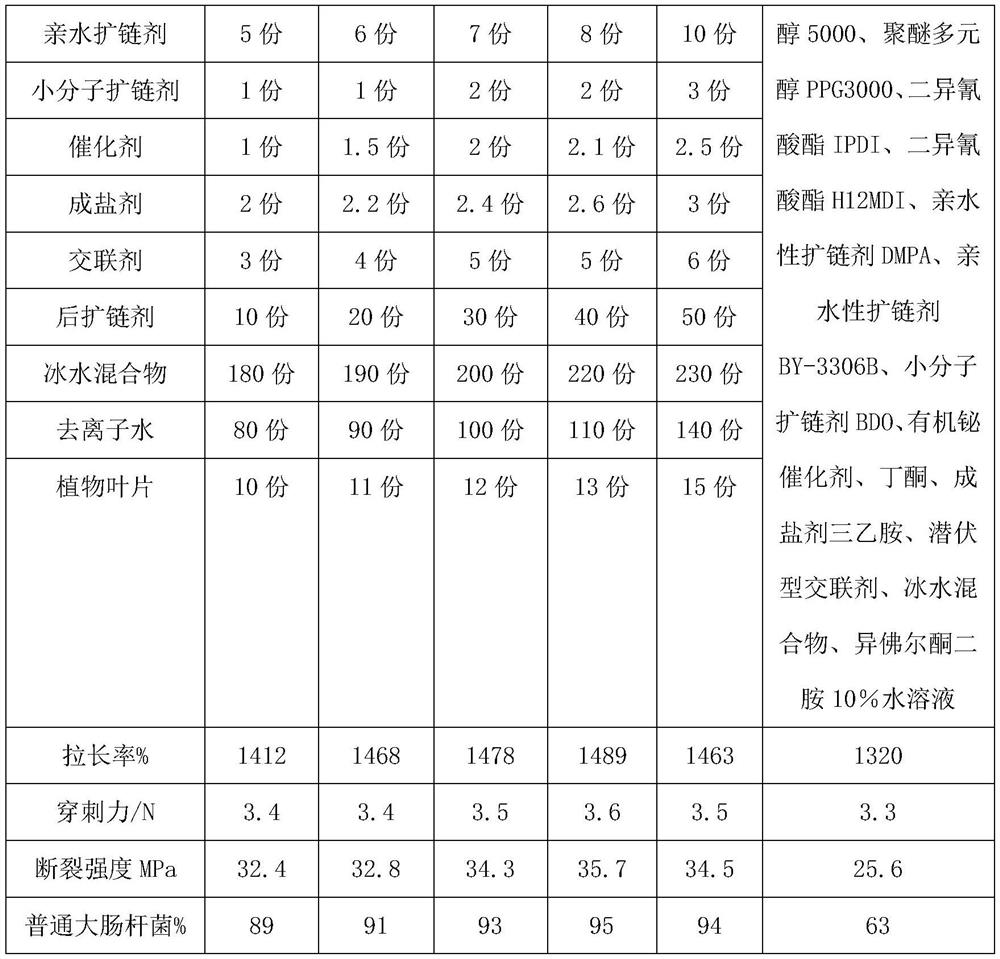

[0025] S1: The raw material consists of the following parts by weight: 30 parts of mixed polyol, 15 parts of macromolecular diol, 5 parts of hydrophilic chain extender, 1 part of small molecule chain extender, 1 part of catalyst, 2 parts of salt forming agent, 3 parts of joint agent, 10 parts of post-chain extender, 180 parts of ice water mixture, 80 parts of deionized water and 10 parts of plant leaves, mixed polyols include polyester polyols, polyether polyols and polyether modified silicone polyols , the post-chain extender contains aminosilane and polyether polyamine, the weight ratio of polyester polyol, polyether polyol and polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com