Cooling Paints and Cooling Coatings

A coating and putty layer technology, applied in the field of coatings, can solve the problems of cumbersome construction procedures, high raw material costs and high construction costs, and achieve the effects of simple construction procedures, reduced raw material costs and construction costs, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

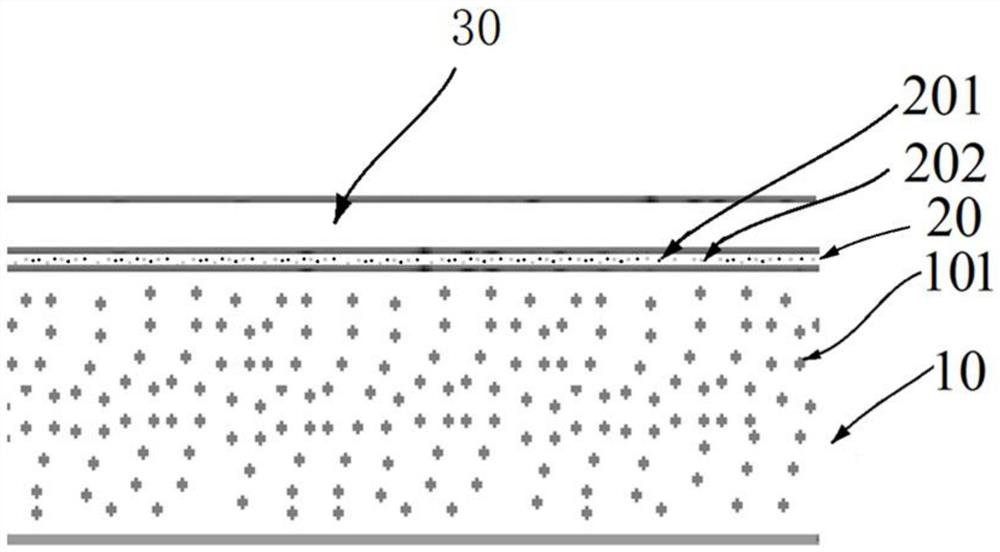

Image

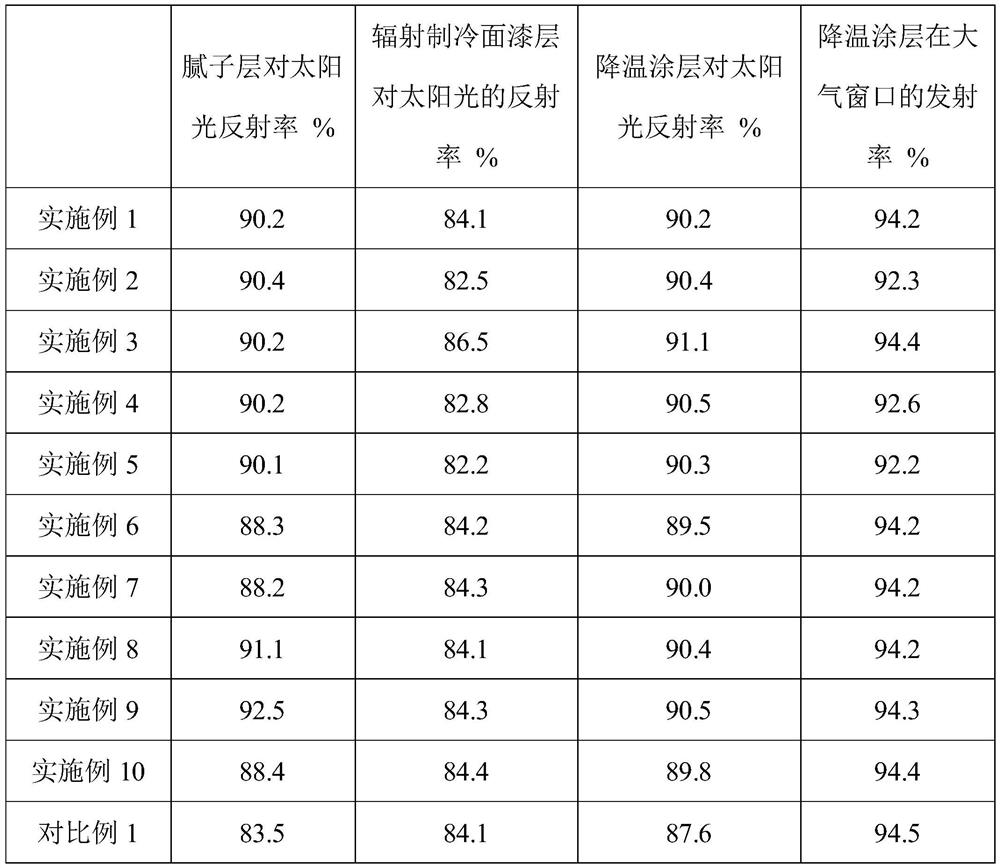

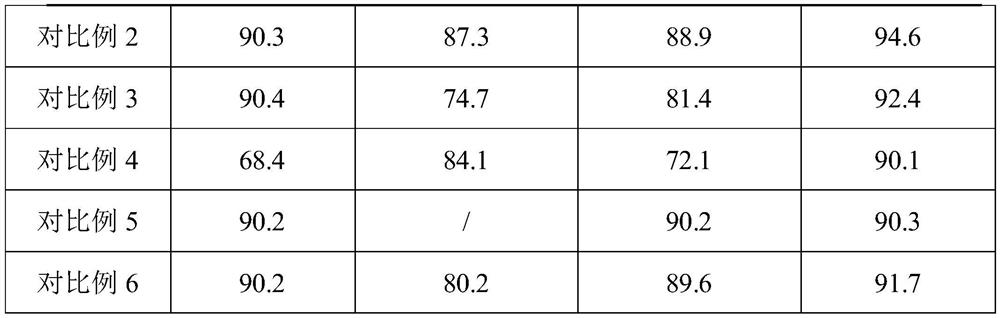

Examples

Embodiment 1

[0067]The cooling paint of Example 1 includes a liquid putty and a radiant cooling paint used in conjunction with the liquid putty.

[0068] Wherein, the liquid putty includes the first resin: 100 parts by weight of epoxy resin, the first filler: 500 parts by weight of barium sulfate, film-forming aid: 9.1 parts by weight of alcohol ester 12, and dispersant: 1.8 parts by weight of polymer Methacrylate, thickener: 0.9 parts by weight of associative polyurethane thickener, defoamer: 0.1 part by weight polydimethylsiloxane, solvent: 25 parts by weight of water, wherein the epoxy resin The elastic modulus is 1.6MPa, and the sunlight transmittance in the 0.3μm-2.5μm band is 91.2%.

[0069] The radiation refrigeration coating comprises the second resin: 100 parts by weight of epoxy resin, the second filler: 8 parts by weight of titanium dioxide, and the third filler: 4 parts by weight of alumina.

[0070] The liquid putty is formed on the surface of the existing base roof, and afte...

Embodiment 2

[0072] Example 2 refers to the implementation of Example 1, except that the thickness of the radiative cooling topcoat layer 20 is 20 μm.

Embodiment 3

[0074] Example 3 refers to the implementation of Example 1, except that the thickness of the radiative cooling topcoat layer 20 is 60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com