AuNPs-p-Ti3C2Tx composite material as well as preparation method and application thereof

A technology of aunps-p-ti3c2tx, composite materials, applied in nanotechnology for materials and surface science, material electrochemical variables, electrolytic coatings, etc., can solve the problem of low sensor conductivity, long analysis time, and complicated measurement problems, to achieve the effect of high specific surface area, accurate and rapid detection, and controllable nano-layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: AuNPs-p-Ti 3 C 2 T X Preparation of composite materials

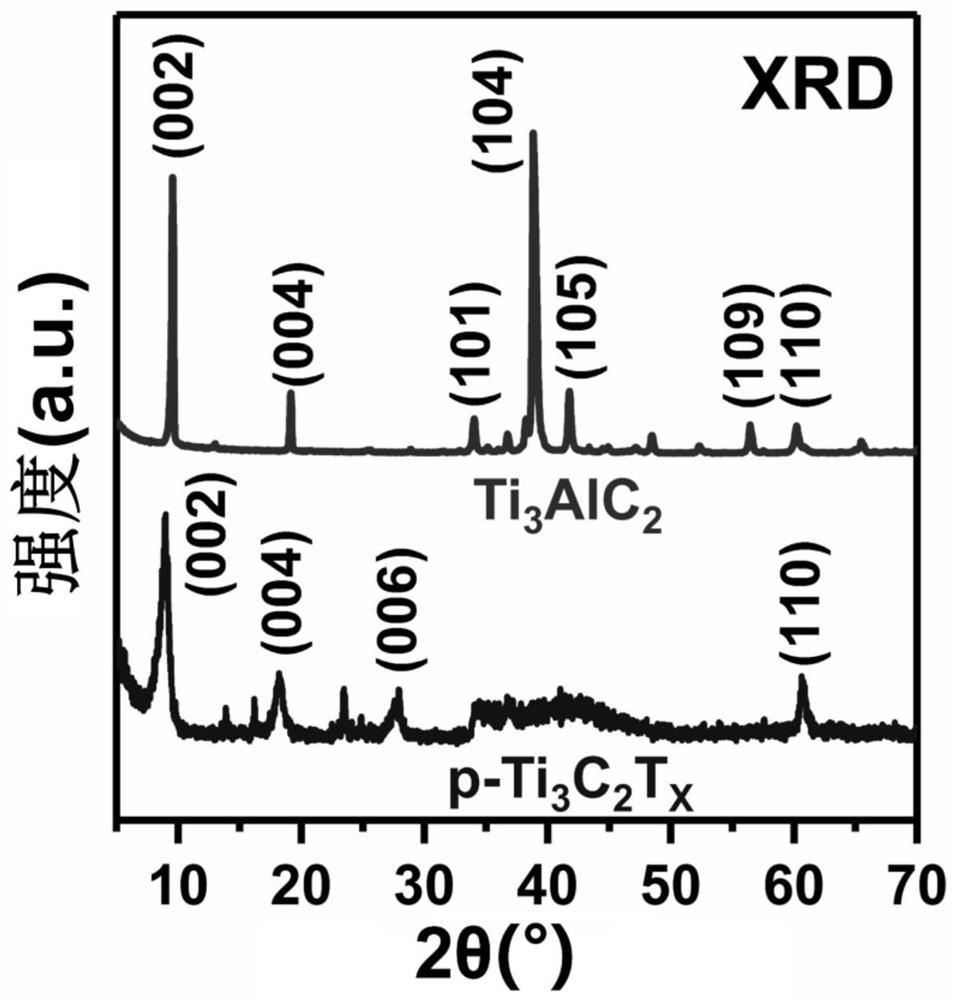

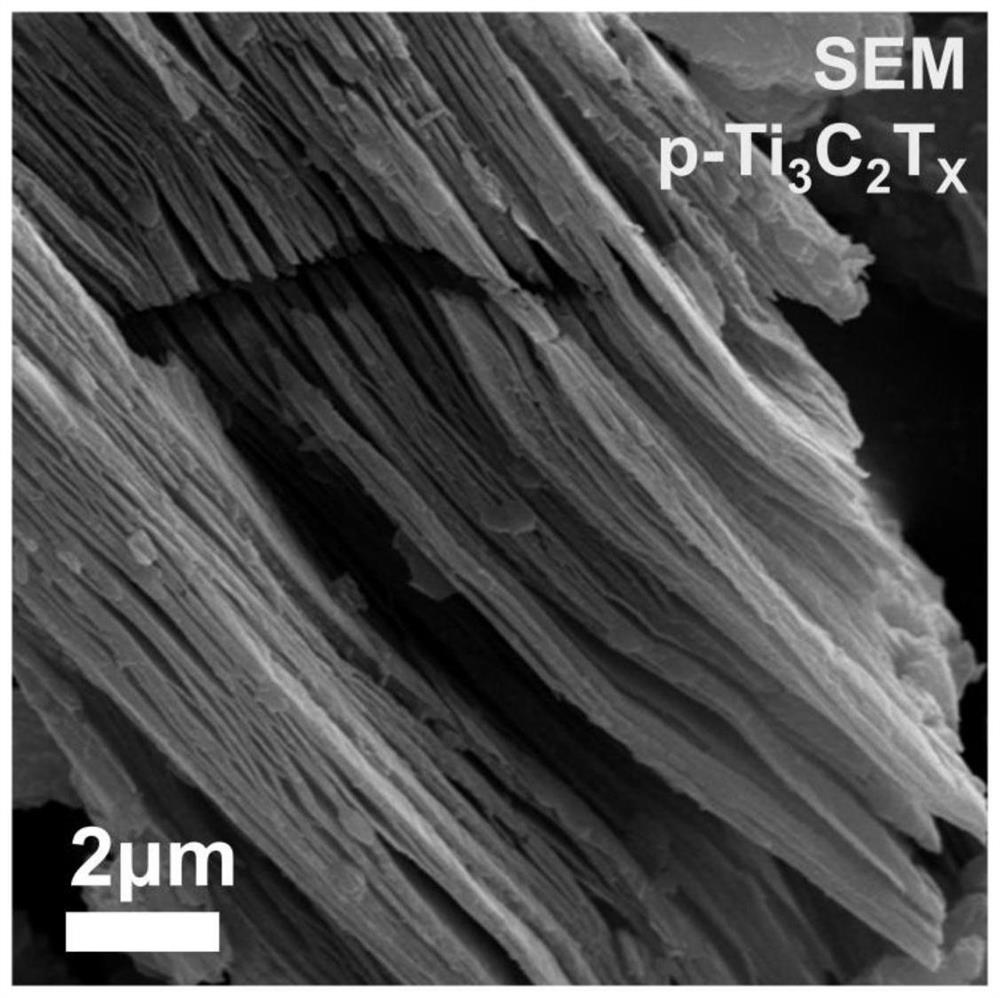

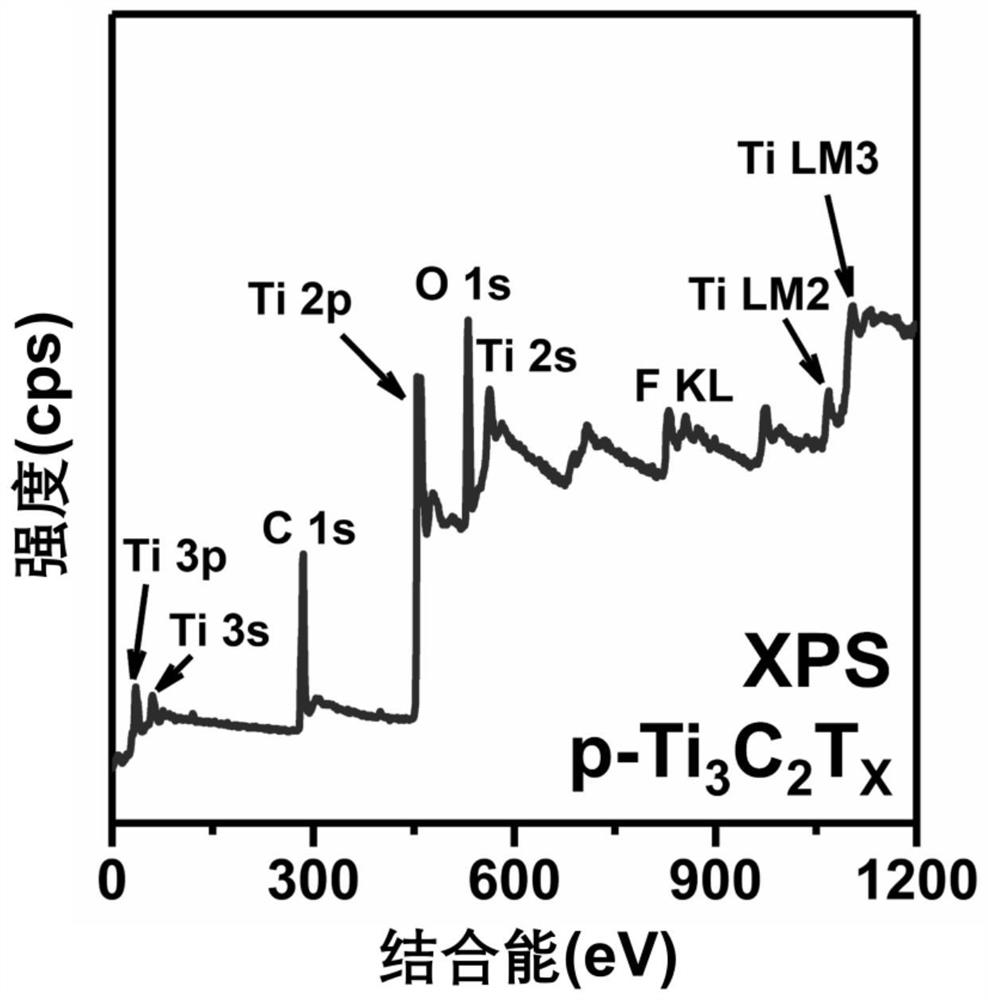

[0039] (1) p-Ti 3 C 2 T x Preparation of:

[0040] Add 2.0 g Ti to 30 mL of 40% HF solution 3 AlC 2 powder, stirred continuously at 25°C for 24 h; the precipitate obtained by centrifugation was repeatedly washed with pure water until the pH value of the washing liquid was 6.0; then the obtained precipitate was vacuum-dried at 30°C for 24 h to obtain Ti 3 C 2 T x powder.

[0041] Take 1.0 g Ti 3 C 2 T x The powder was dispersed in 250 mL of pure water, and after sonication for 1 h, the suspension was centrifuged at 10,000 rpm for 15 min and the supernatant was collected. Take 80 mL supernatant and 80 mL 0.2 mol / L CuSO 4 Mix well, and stir continuously at room temperature for 30 min; centrifuge to obtain a precipitate, wash with pure water repeatedly until the pH of the washing solution is 6.0, then add 40 mL of 5% HF and let it stand for 10 min. Finally, the precipitate was obtained by c...

Embodiment 2

[0050] Embodiment 2: Based on AuNPs-p-Ti 3 C 2 T x Fabrication of Bimolecular Imprinted Sensors from Composite Materials

[0051] Figure 6 For AuNPs-p-Ti based 3 C 2 Tx Schematic diagram of the bimolecularly imprinted sensor and the electrochemical detection of cadaverine and putrescine, which is based on AuNPs-p-Ti 3 C 2 T x The preparation method of the bimolecularly imprinted sensor such as Figure 6 Shown:

[0052] Take 20 μL of the composite material AuNPs-p-Ti obtained in Example 1 3 C 2 T x Drop-coated on the screen-printed electrode (SPCE), and dried by an infrared lamp for 3-5 minutes to obtain a highly conductive sensing interface AuNPs-p-Ti 3 C 2 T x / SPCE; then AuNPs-p-Ti 3 C 2 T x / SPCE immersed in 0.1 mol / L PBS solution (pH8.0) containing cadaverine template, putrescine template and functional monomer (MAA), the molar ratio of the three is 1:1:1~7; The safety method (CV) scans 5-30 cycles to build a MIP layer on the electrode surface, the poten...

Embodiment 3

[0056] In this example, in order to increase the response current, the molar ratio of cadaverine, putrescine and functional monomer MAA was optimized to prepare a MIP film.

[0057] Figure 8 is an optimized graph of the molar ratio between the dual-template molecules (cadaverine and putrescine) and the functional monomer, from Figure 8 It can be seen that when the molar ratio of the three is in the range of 1:1:1~1:1:5, the current response gradually increases, which helps to form more imprinted cavities, and the molar ratio exceeds 1:1: At 5 o'clock, the response current drops because the formed electron channel is covered by excess monomer. Therefore, in this embodiment, the molar ratio of cadaverine, putrescine template and MAA is 1:1:5 to establish the sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com