Production technology and equipment of new type busway

A production process and production equipment technology, which is applied to the production process of new busway and its equipment field, can solve problems such as unsatisfactory safety, and achieve the effects of avoiding accidental drop, simple production process, and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

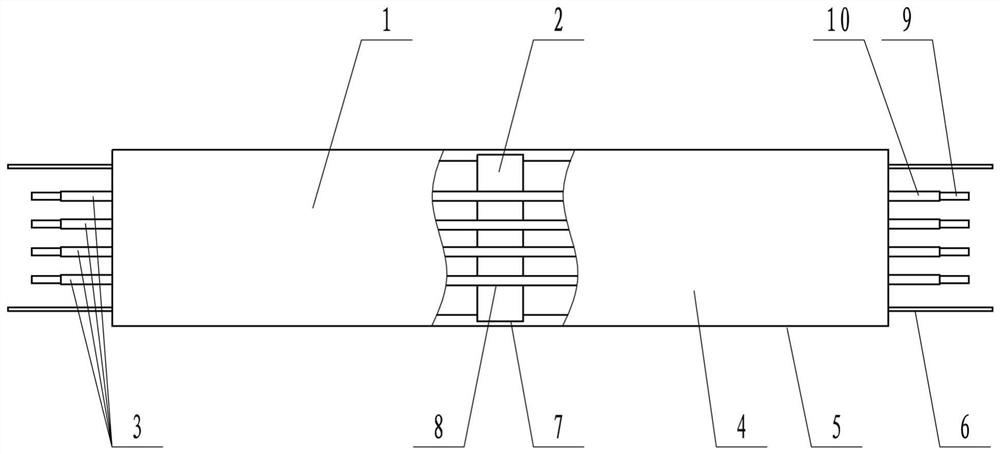

[0048] Step 4: the joint side folded plate 5 is installed on the end of the side support plate 5 by a pneumatic tightening machine.

[0049] So far, the production of the novel busway is completed, and after subsequent inspection and packaging, it is a finished product.

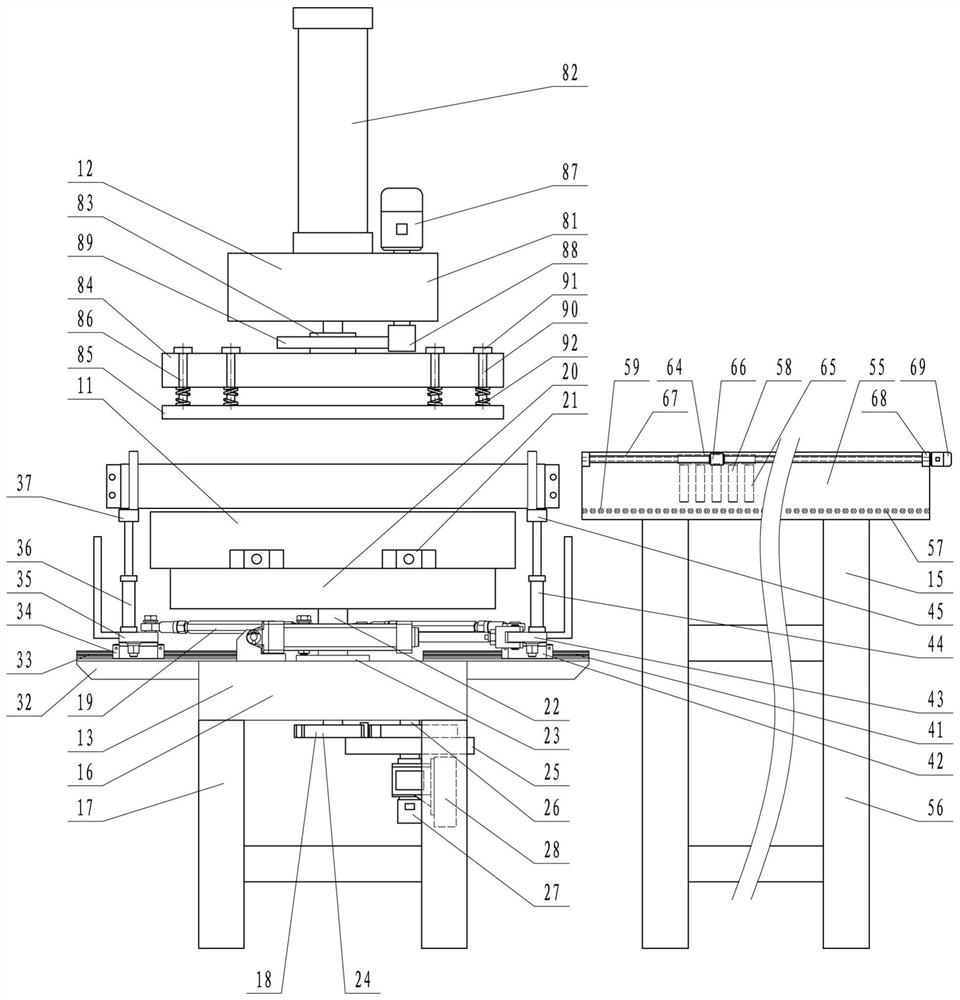

[0059] The flexible connector 86 includes a flexible connecting column 90, a flexible connecting column limit block 91, and a flexible connecting compression spring 92, so

[0060] The press-fitting frame 81 is provided with a press-fitting swing limiter plate, which can realize the

[0062] The above content described in this specification is only an illustration of the present invention. The technology to which the present invention belongs

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com