Processing performance additive and preparation method thereof

A technology of processing modification and additives, which is applied in the field of processing modification additives and its preparation, can solve the problems of CPVC fire pipe Vicat softening point decrease and flame retardant performance degradation, so as to improve processing performance, reduce processing load, The effect of improving overall performance

Active Publication Date: 2021-11-30

WUXI HONGHUI NEW MATERIALS TECH

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to improve the processing performance of CPVC fire pipes, the common method is to add acrylic processing aid ACR and impact modifier MBS to the CPVC resin formulation system. It will lead to a higher torque of CPVC during processing, and it will also lead to a decrease in the Vicat softening point of the CPVC fire pipe and a decrease in flame retardancy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

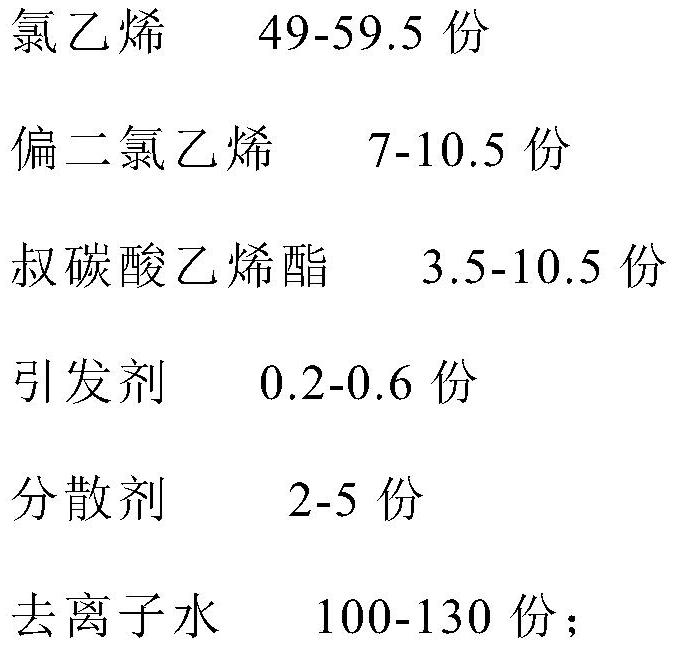

[0029] Processing modifiers, in parts by weight, include the following components:

[0030]

[0031]

Embodiment 2

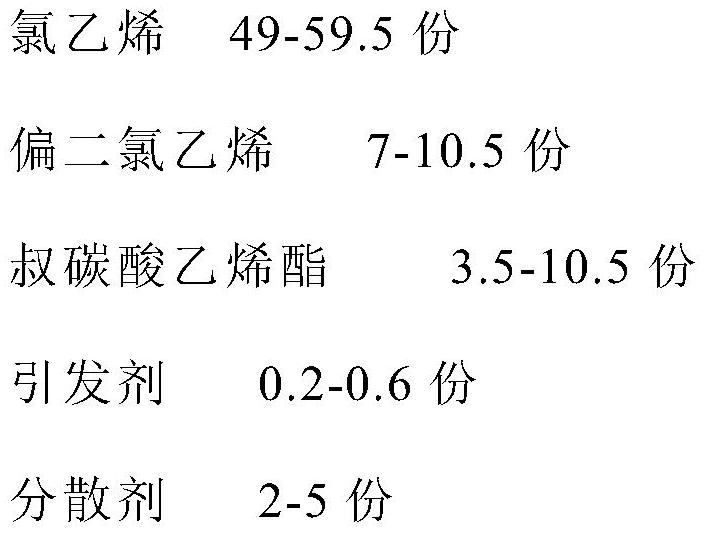

[0033] Processing modifiers, in parts by weight, include the following components:

[0034]

Embodiment 3

[0036] Processing modifiers, in parts by weight, include the following components:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of high polymer materials, in particular to a processing performance additive and a preparation method thereof. An acrylic ester processing agent ACR and an impact modifier MBS are added into a CPVC resin formula system, and the processing agent ACR and the impact modifier MBS can cause high torque of CPVC in the processing process and can also cause reduction of the vicat softening point of a CPVC fire-fighting pipe in the using process. Based on the problems, the invention provides a processing performance additive. The processing performance additive is obtained by copolymerizing vinyl chloride, vinylidene chloride and vinyl versatate as raw materials. The chain structures of vinyl chloride and vinylidene chloride in the molecular structure of the processing performance additive have good compatibility with CPVC, which is benficial to the improvement of the comprehensive performance of the CPVC fire-fighting pipe.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to a processing modification aid and a preparation method thereof. Background technique [0002] In recent years, thanks to the vigorous development of real estate and the needs of the renovation of old communities, plastic pipes have achieved unprecedented development. Among them, CPVC fire-fighting pipes are favored by people because of their flame-retardant, heat-resistant, chemical-resistant, antibacterial, and long-life characteristics, and their usage is increasing. [0003] The application of CPVC fire-fighting pipes has high requirements for its processing performance, heat resistance, flame retardancy and impact resistance. In order to improve the processing performance of CPVC fire pipes, the common method is to add acrylic processing aid ACR and impact modifier MBS to the CPVC resin formulation system. It will lead to a higher torque of CPVC during processing,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F214/06C08F214/08C08F218/10C08L27/24C08L27/06

CPCC08F214/06C08L27/24C08L2203/18C08F214/08C08F218/24C08L27/06

Inventor 孙立坤陈建溢姚宏华时劲松项梁

Owner WUXI HONGHUI NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com