Semiconductor gas sensor and automatic packaging method thereof

A gas sensor and packaging method technology, which is applied in the fields of gaseous chemical plating, decorative arts, microstructure devices, etc., can solve the problems of easy leakage, blocked ventilation holes of protective caps, low packaging accuracy, etc., and achieves improved detection accuracy and packaging. Fast and efficient, good electrical connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

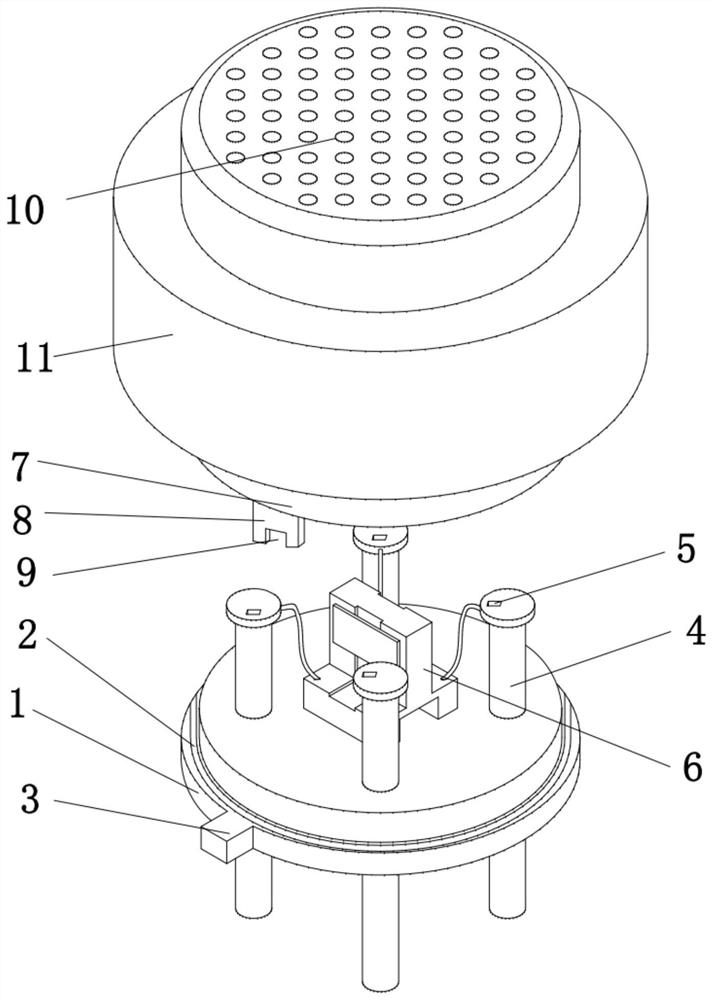

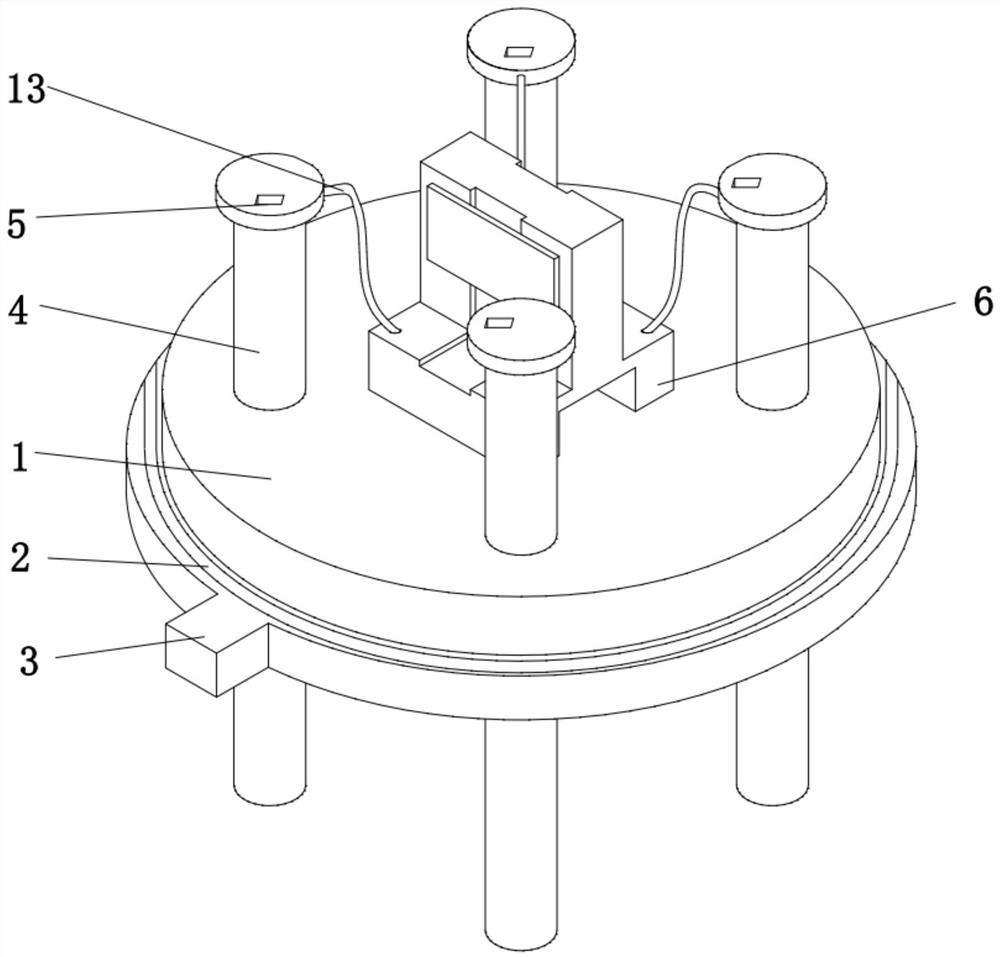

[0034] Such as Figure 1-4 , a semiconductor gas sensor, comprising a tube base 1, a plurality of groups of terminal posts 4 are plugged in a uniform array inside the tube base 1, the terminal posts 4 are located at the bottom part of the tube base 1 and connected to an alarm, and the top of the tube base 1 is provided with The substrate holder 19 can be packaged on the top of the tube holder 1 by automatic packaging methods such as solid crystal and wire bonding. The top of the substrate holder 19 is provided with a gas sensor unit 6, and the monitoring of the gas is realized through the gas sensor unit 6. The tube holder The top of 1 is sleeved with a protective cap 7, and the protective cap 7 protects the internal structure.

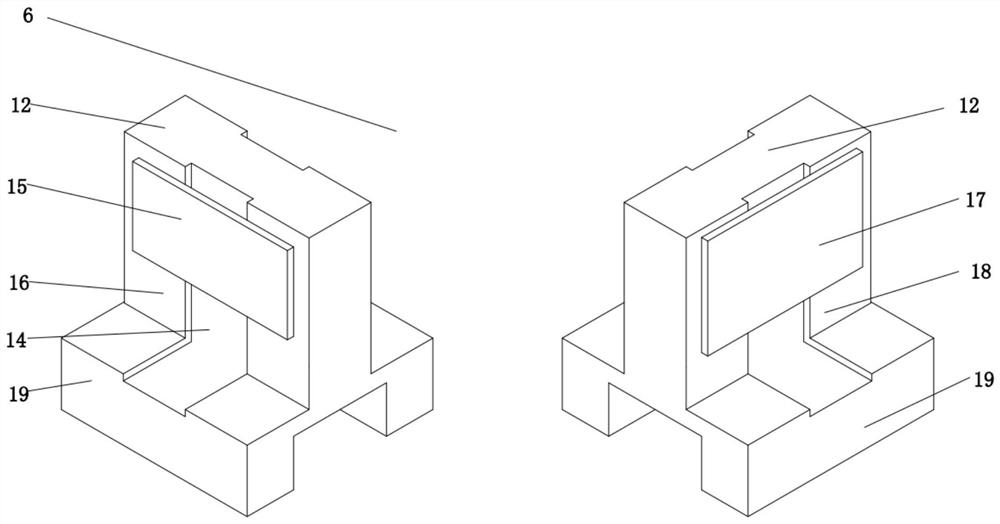

[0035]Gas-sensitive unit 6 comprises substrate sheet 12, and substrate holder 19 and substrate sheet 12 are all good heat insulating properties and the material of high temperature resistance, as quartz, and substrate holder 19 is " U " shape, and sub...

no. 2 example

[0041] Such as Figure 5 with Image 6 , based on a semiconductor gas sensor provided in the first embodiment, in actual use, due to problems such as vibration in the environment, the structure inside the protective cap 7 will be damaged, and the detection effect of the gas sensitive material 15 is the same as that of the gas When the flow rate of the detection gas reaches the position of the gas-sensitive material 15 through the vent hole 10, the flow rate is too large or too small, which will affect the detection results. Generally, the flow rate of the detection gas is preferably 500-1000 sccm, and, In order to make the measurement accuracy of the semiconductor gas sensor higher, the gas flow rate flowing through the sensor should be kept constant as much as possible. In order to solve the above problems, improve the anti-seismic efficiency and assembly efficiency of the device, and ensure that the flow rate of the detected gas is stable and controllable, the semiconductor ...

no. 3 example

[0051] Such as Figure 7 , based on the semiconductor gas sensor provided in the second embodiment, in order to ensure the fast, accurate and tightness of the package in actual packaging, it is necessary to carry out reasonable packaging program planning and arrangement according to the actual operation situation, so this embodiment provides a Automated packaging method for semiconductor gas sensors:

[0052] S1. Make a patterned metal electrode on the top of the substrate holder 19 by using a coating method, wherein the coating process mainly includes evaporation, sputtering, electroplating or screen printing, and the metal electrode can be made of gold or platinum;

[0053] S2. Make a deep groove 14 on the top of the substrate holder 19 through a groove-making process, wherein the groove-making process mainly includes precision cutting, corrosion or sandblasting;

[0054] S3. Use the blue film to fix and cut the substrate seat 19, and then expand the film to form a U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com