Preparation method of ZIF-67 and ZIF-67 derivative cobalt selenide/carbon electrode material

A technology of ZIF-67 and cobalt selenide, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of accelerating the commercialization and industrialization of MOF-based negative electrode materials, toxic solvents, low yield, etc., and achieve accelerated commercialization and industrialization, improve conductivity, and accelerate the effect of efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, KOH and 2-methylimidazole were added to deionized water successively, and after ultrasonication for 5 minutes and magnetic stirring for 10 minutes, a mixed solution A was obtained; then Co(NO 3 ) 2 ·6H 2O was dissolved in deionized water to prepare solution B. Under the condition of stirring, solution B was added into solution A, and after stirring for 6 hours, the polyhedral ZIF-67 powder was centrifuged, washed and dried. The reaction temperature was 12°C. 2-Methylimidazole and Co(NO 3 ) 2 ·6H 2 The molar ratio of O is about 8:1, and the molar concentration of KOH in the reaction solution is 3mol L -1 .

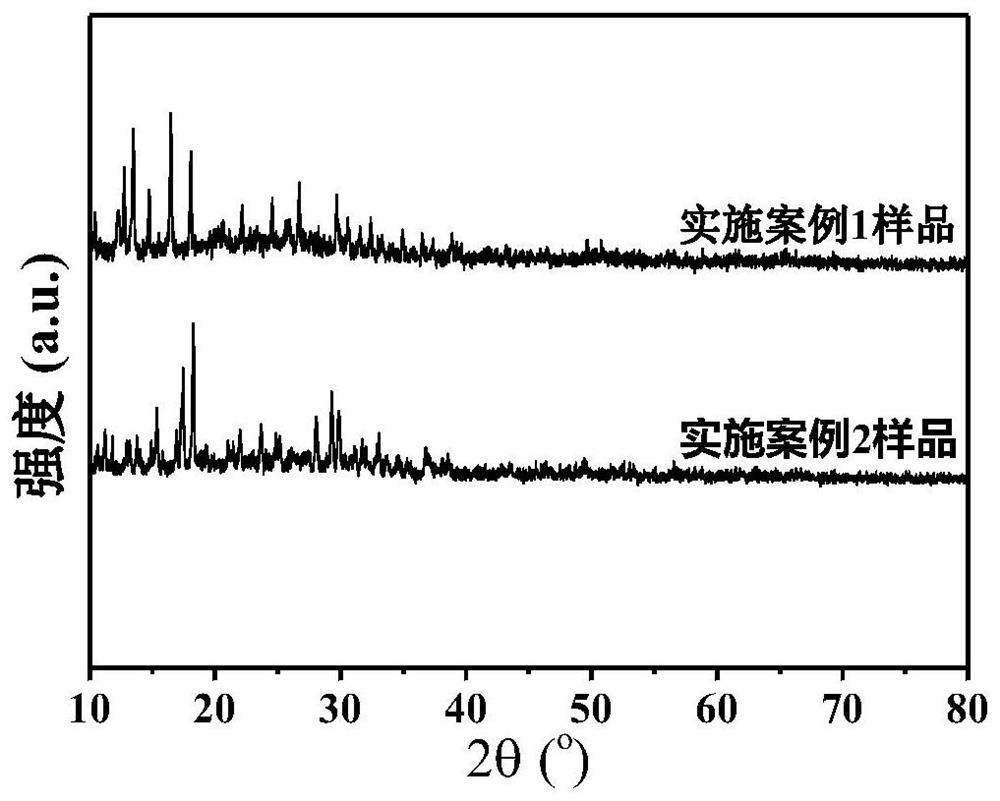

[0037] Depend on figure 1 It can be seen that the XRD spectrum of the prepared ZIF-67 material shows that the position of the characteristic peak of the material is consistent with that of the standard peak of ZIF-67, indicating that the synthesized product is ZIF-67.

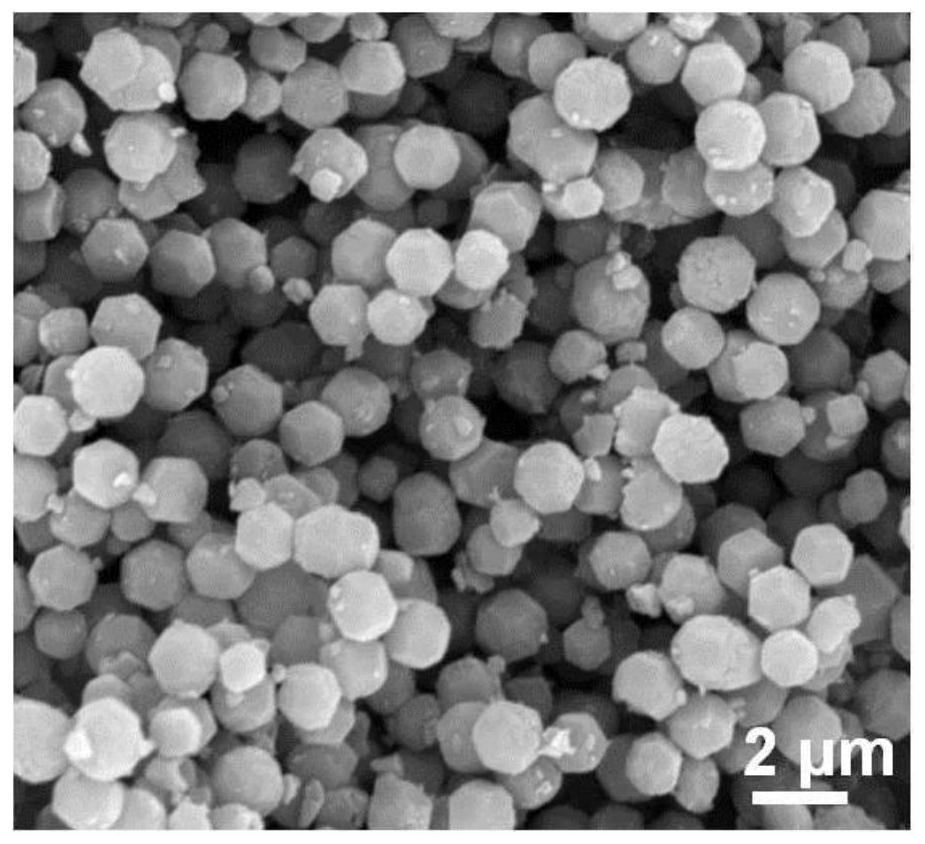

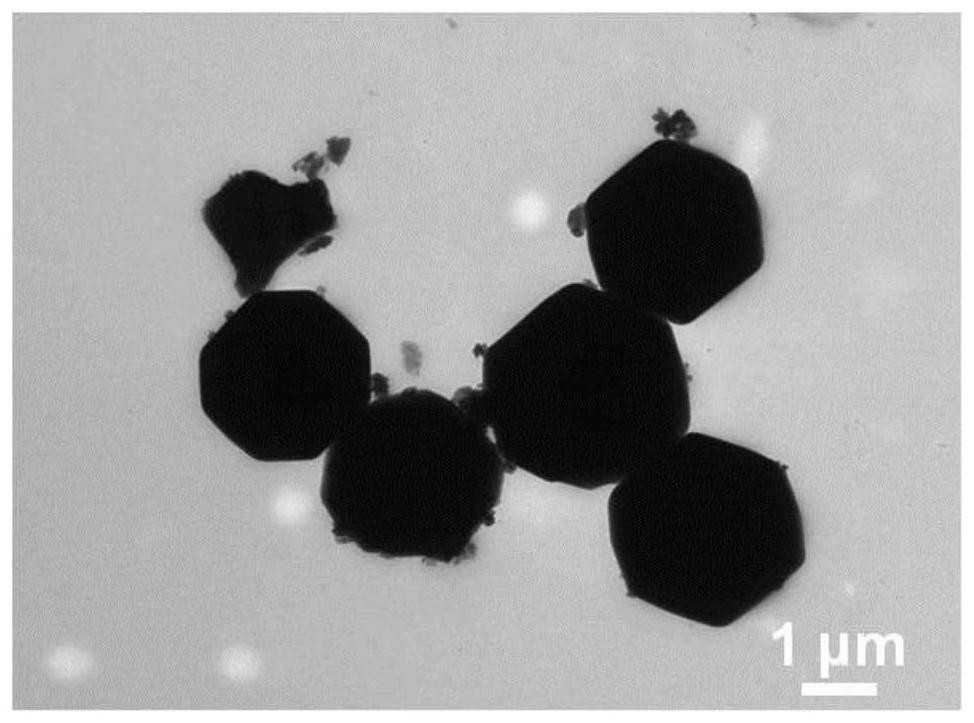

[0038] Depend on figure 2 It can be seen that the SEM image of the prepared ZIF-...

Embodiment 2

[0041] The difference from Example 1 is that the concentration of KOH is 0.1mol L -1 . Figure 4 The SEM image in shows that when the concentration of KOH is 0.1mol L -1 , the morphology of the obtained product is still dominated by two-dimensional leaf-like structures, but the thickness of the sheets prepared by this method is larger than that of the reported aqueous solution; in addition, a three-dimensional carambola-like structure is also found in the picture , indicating that with the addition of KOH, the morphology of the product tends to change from a two-dimensional structure to a three-dimensional structure.

Embodiment 3

[0043] The difference from Example 1 is that the concentration of KOH is 1mol L -1 . Such as Figure 5 As shown, SEM shows that the obtained material is mainly three-dimensional granular structure with only a small amount of two-dimensional structure. Compared with Example 2, it can be seen that 2mol L -1 KOH further induced the ZIF-67 crystal to change from two-dimensional growth to three-dimensional growth. It can be seen that the addition of high concentration of KOH can accelerate the change of crystal growth direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com