Paper diaper core and preparation method thereof

A diaper and core technology, applied in the field of diaper core and its preparation, can solve the problems of waste, user's skin rash, low utilization rate, etc., and achieve the effect of reducing production cost and excellent material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to more clearly illustrate the features and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings. As a specific limitation of the protection scope of the present invention.

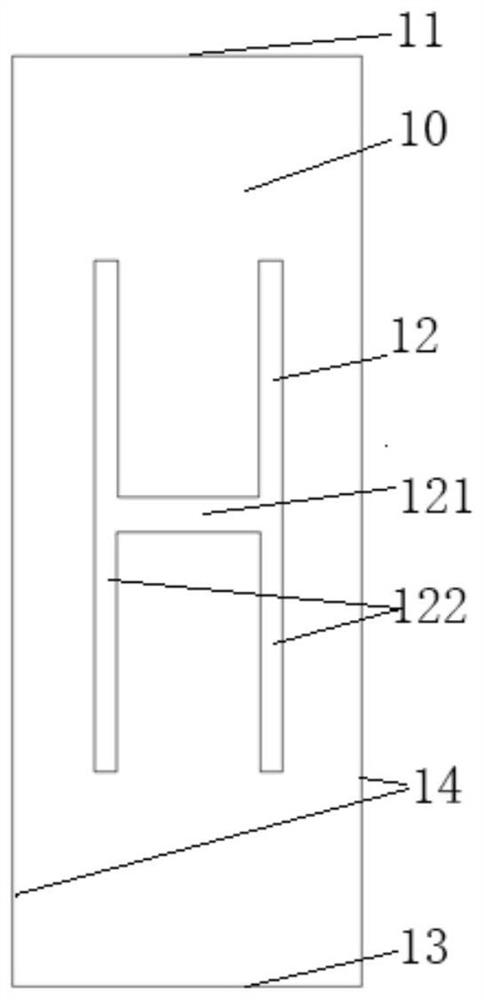

[0026] figure 1 It is a schematic diagram of the diaper core body of the present invention. like figure 1 As shown, the present invention provides a diaper core, which includes a multi-layer absorbent core 10, on which an H-shaped flow guide groove 12 is formed.

[0027] According to the absorbent core of the diaper of the present invention, the absorbent core has a 5-layer structure, which are: the first coating layer, the first polymer layer, the loose cotton layer, the second polymer layer, and the second coating layer. The H-shaped diversion groove runs through the 5-layer structure of the absorbent core (not shown in the figure). Wherein, the first covering layer is the side in contact with the user's skin, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com