Method for repairing heavy metal polluted farmland

A heavy metal and farmland technology, applied in the restoration of polluted soil, etc., can solve the problems of limited activation capacity of heavy metals, small plant biomass, increased carbon dioxide emissions, etc., achieve good social and environmental benefits, facilitate popularization and application, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

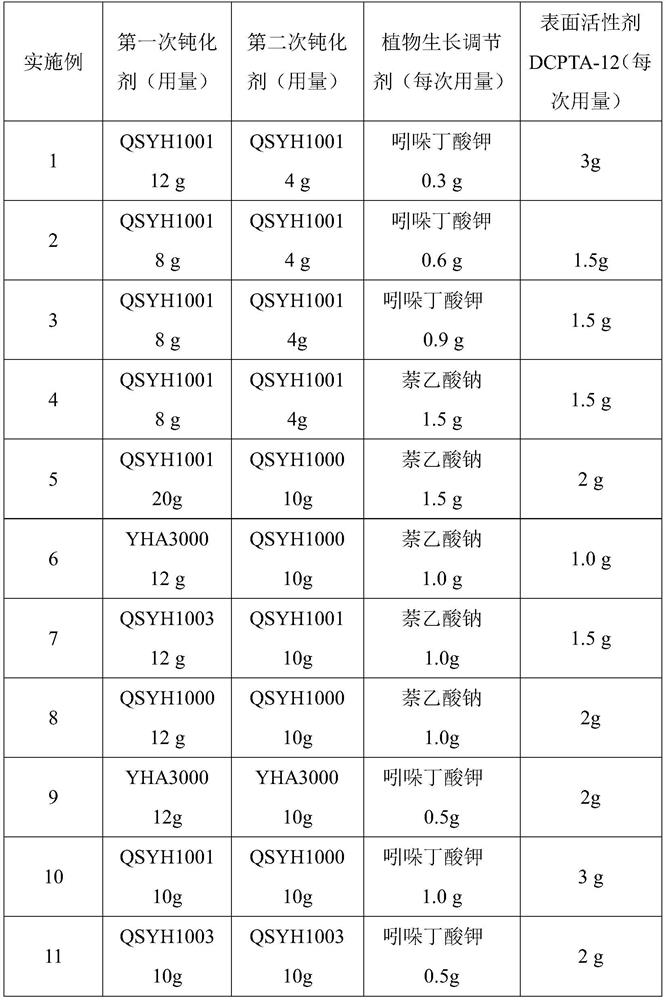

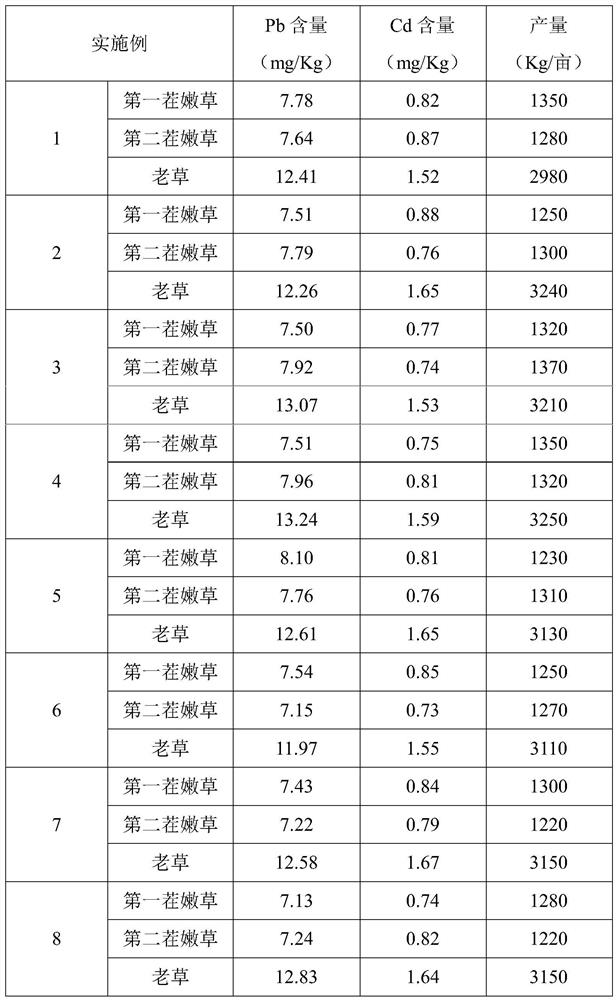

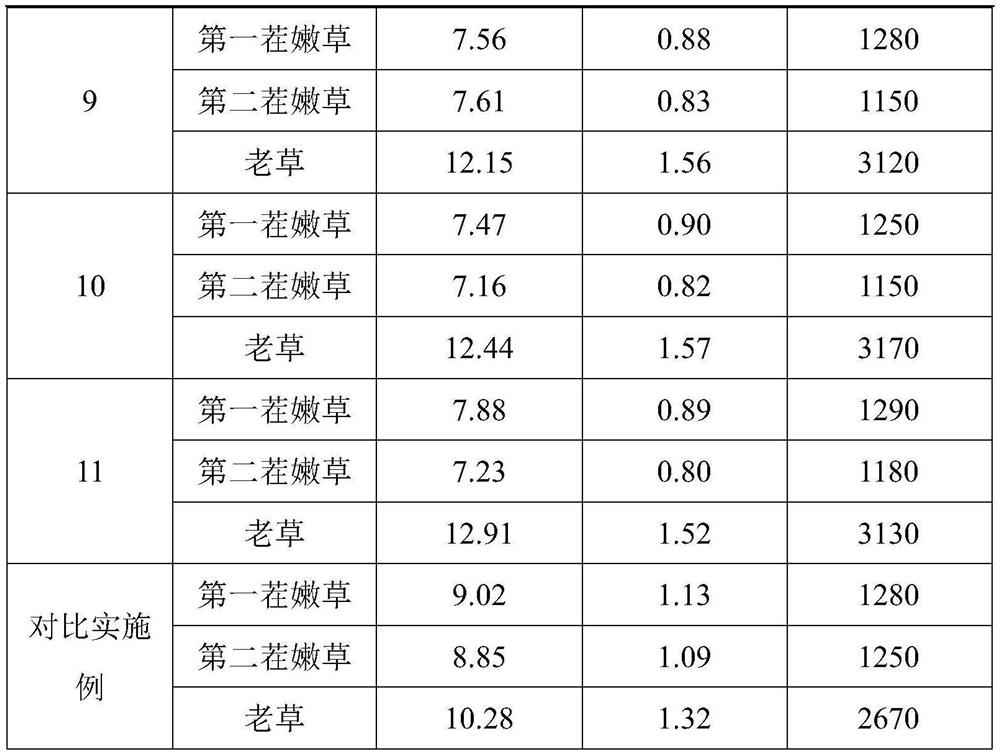

Embodiment 1-11

[0017] Divide a piece of heavy metal polluted farmland (Cd content in soil is 3.3mg / kg; Pb content is 280mg / kg) divided into 20m*5m each test field. On April 3, 2019, Oasis No. 1 was planted uniformly, watered and passivating agent was applied the next day. On May 20, 2019, Oasis No. 1 grew to a height of about 1.0-1.3 meters. The first crop of tender grass was harvested, and the passivator was applied again the next day after watering. On June 15, 2019, Oasis No. 1 grew to a height of about 1.0-1.3 meters, and the second crop of tender grass was harvested. After ten days, water and apply plant growth regulator and surfactant at the same time, water again one month later and apply the same amount of plant growth regulator and surfactant, and harvest old grass at the end of December, 2019. The yields of the first young grass, the second young grass and the old grass were measured respectively and their lead and cadmium contents were determined.

[0018] According to the same ...

Embodiment 12

[0026] The synthetic method of embodiment 12 [2-(3,4-dichlorophenoxy)-ethyl] dodecyl diethylammonium bromide (DCPTA-12)

[0027] Add 50 g of [2-(3,4-dichlorophenoxy)-ethyl] diethylamine into 100 mL of ethyl acetate solution, then add 50 g of 1-bromododecane, heat to reflux for 6 hours, add petroleum jelly after cooling Ether was stirred, and the solid was filtered out, washed with petroleum ether and vacuum-dried to obtain the product [2-(3,4-dichlorophenoxy)-ethyl]dodecyldiethylammonium bromide 88g, yield 90% .

[0028] 1 HNMR (400MHz, CDCl 3 )δ7.37(d, J=9.2Hz, 1H), 7.05(d, J=2.8Hz, 1H), 6.91(dd, J 1 =9.2Hz,J 2 =3.2Hz,1H),4.59(t,J=4.6Hz,2H),4.20(t,J=4.4Hz,2H),3.66-3.60(m,4H),3.41-3.37(m,2H),1.79 (m,2H),1.48(t,J=7.2Hz,6H),1.38-1.26(m,18H),0.88(t,J=6.8Hz,3H);

[0029] 13 C NMR (100MHz, CDCl 3 )δ 155.9, 132.9, 130.8, 125.2, 116.7, 114.3, 62.6, 59.1, 57.1, 54.9, 31.7, 29.4, 29.2, 29.2, 29.1, 29.0, 26.3, 22.4, 22.1, 13.9, 8.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com