Film laminating machine for photovoltaic solar module

A photovoltaic solar energy, laminating machine technology, applied in electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of low work efficiency, affecting cutting work, and the protective film being easily adsorbed on the cutting knife, etc. Achieve the effect of improving processing efficiency, improving applicability, and improving lamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

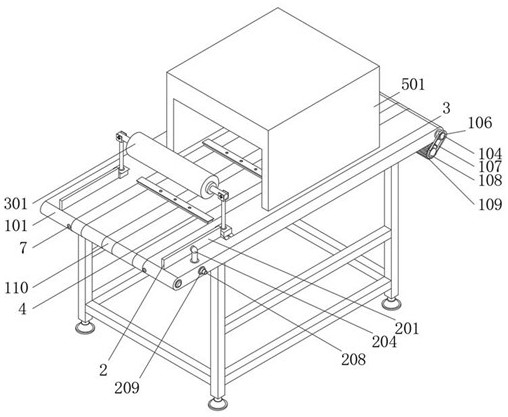

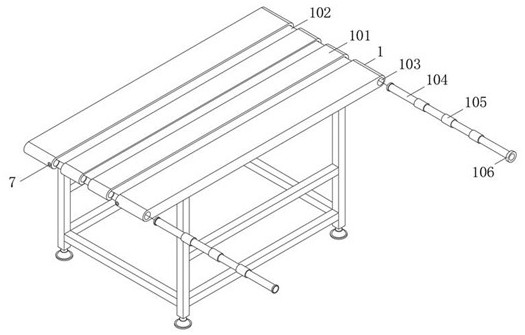

[0048] The specific embodiment is: control the operation of the electric motor 109, and the output shaft of the electric motor 109 will use the linkage effect between the driving wheel 108, the belt 107 and the driven wheel 106 to transmit the torque to the driving shaft 104 during the working process. , and use the roller shaft 105 on the drive shaft 104 to drive the photovoltaic solar modules on the transmission belt 110 to perform transmission operations in the transmission groove 102. The transmission groove 102 can have a good calibration and stabilization effect on the transmission belt 110, preventing the transmission belt from 110 Offset and jitter occur during transfer operations.

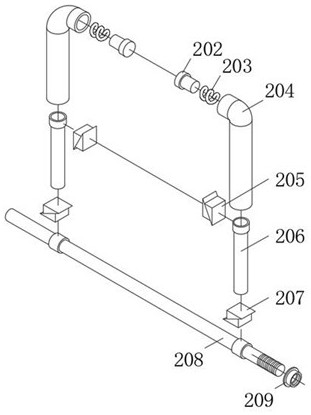

[0049] Specifically, such as figure 1 with 6 As shown, the positioning guide mechanism 2 includes a positioning deflector 201, the positioning deflector 201 is slidably connected to the position corresponding to the conveyor belt 110 on the top of the workbench 101, and the side of the po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap