Complex-phase microwave dielectric ceramic and cold sintering preparation method thereof

A microwave dielectric ceramic and microwave dielectric technology, which is applied in the field of electronic ceramic materials, can solve the problems of difficult cold sintering technology preparation, etc., and achieve the effect of low dielectric constant and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

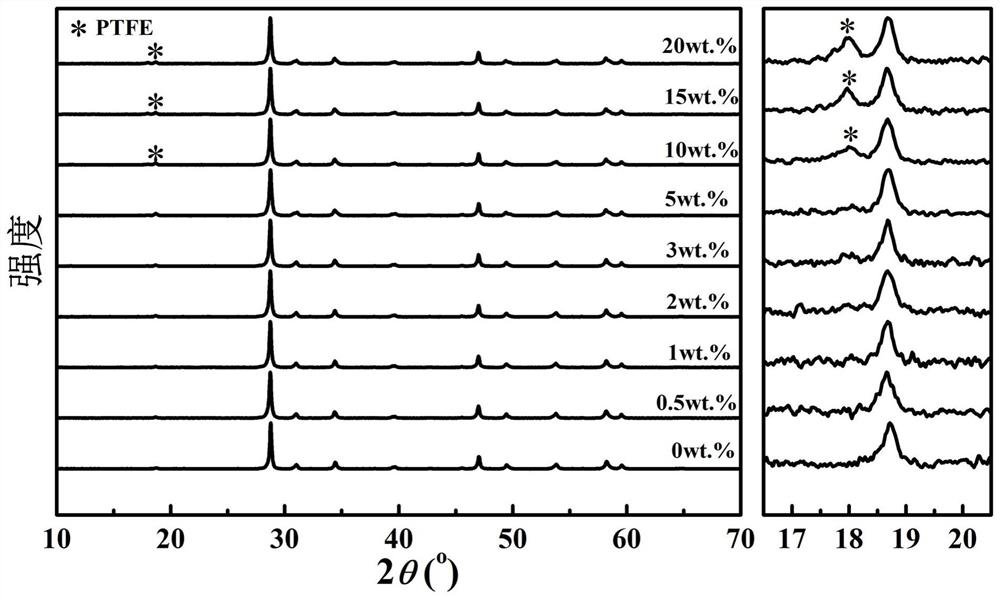

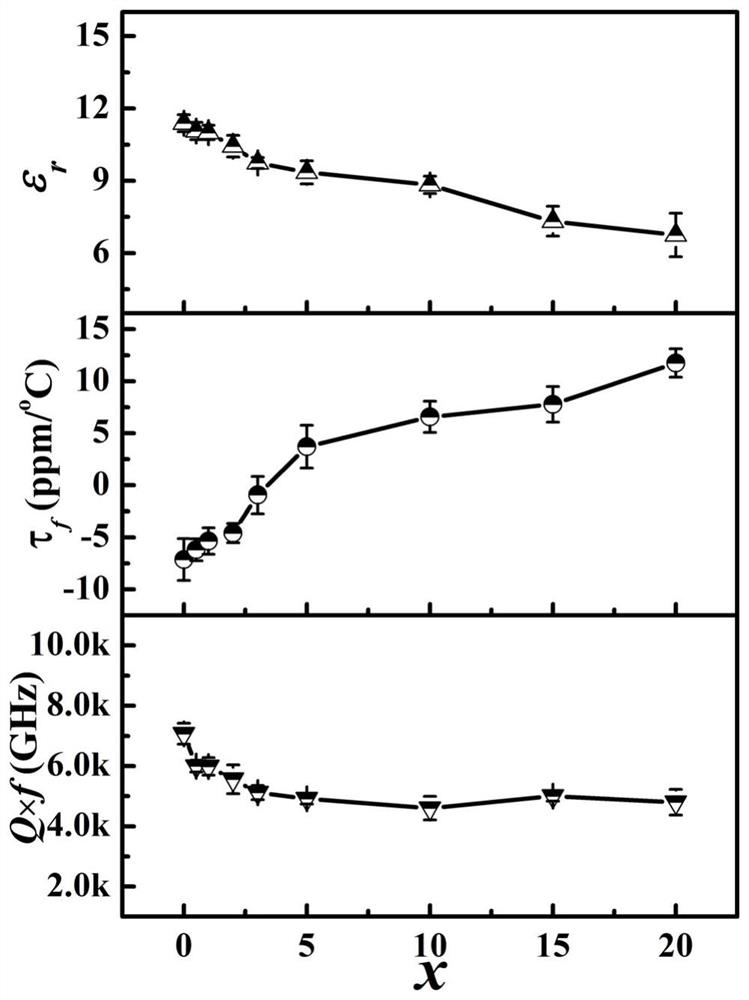

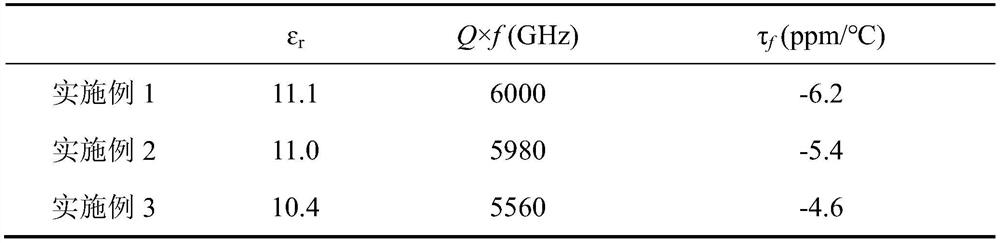

[0018] (1) According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -0.5wt.% PTFE Weigh the CBMVO-LMO and PTFE, use absolute ethanol as the medium, pass through a planetary ball mill for 10-12 hours, and then dry at 80°C. Weigh an appropriate amount of mixed powder and put it into an agate mortar, add 7wt.% deionized water, grind for 5 minutes, pass the ground powder through an 80-mesh sieve, and put it into a hot pressing mold (diameter 11mm) at a temperature of 150°C and 300MPa Molded under the pressure, heat preservation for 1h, and then dried at 120°C for 12h to obtain the target composite material.

Embodiment 2

[0020] According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -1wt.% PTFE Weigh CBMVO-LMO and PTFE, other same as embodiment 1.

Embodiment 3

[0022] According to the chemical formula (Ca 0.65 Bi 0.35 )(Mo 0.65 V 0.35 )O 4 -5wt.%Li 2 MoO 4 -2wt.% PTFE Weigh CBMVO-LMO and PTFE, other same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com