Self-repairing and recoverable vegetable oil-based polyurethane material as well as preparation method and application thereof

A polyurethane material and vegetable oil-based technology, applied in the field of polyurethane materials, can solve the problems of irreparable and reprocessed mechanical properties, and achieve the effects of excellent recycling performance, excellent self-repair and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

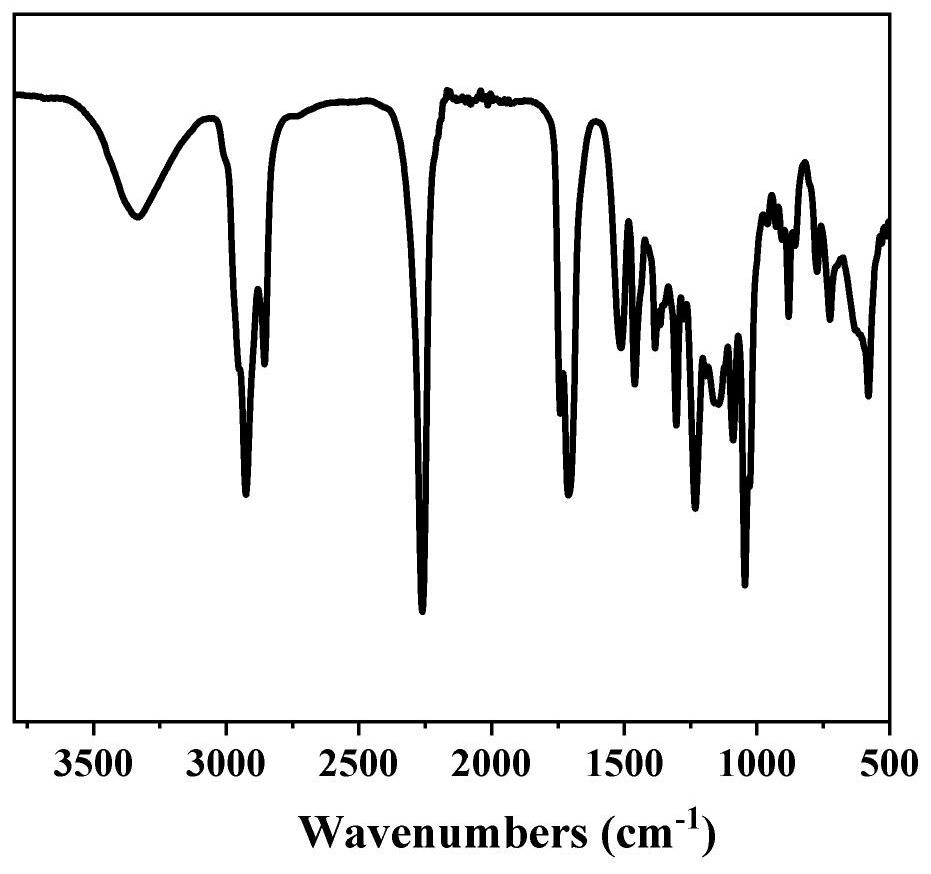

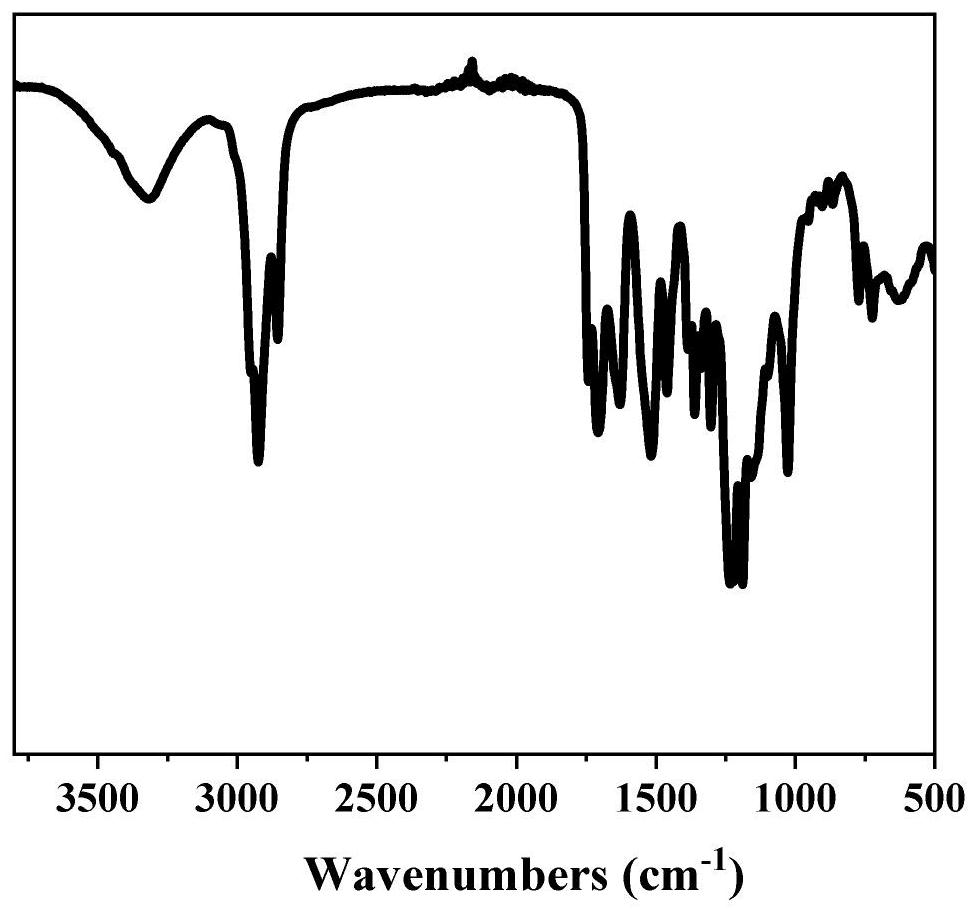

[0022] A self-repairing, recyclable vegetable oil-based polyurethane material and its preparation method and application, the preparation steps are: (1) adding vegetable oil, diisocyanate, diol and catalyst into a reactor, the molar ratio of vegetable oil to diisocyanate being 1 : (1~10), the molar ratio of dibasic alcohol and diisocyanate is 1:(1~10), the catalyst addition is 0.02~2% of the total weight of the reaction material, stirs and heats to 20~100 ℃ reaction 1 ~10h to obtain vegetable oil-based polyurethane intermediate product; (2) Add N,N'-di-tert-butylethylenediamine to the above reactor, the molar ratio of N,N'-di-tert-butylethylenediamine to diisocyanate 1: (0.5~4), heated to 0~100°C for 0.5~3h to obtain vegetable oil-based polyurethane resin; 0.5-20MPa, hot-pressing time 5-60min, to obtain vegetable oil-based polyurethane material.

[0023] Preferably, the vegetable oil described in step (1) is castor oil, tung oil, linseed oil, rubber seed oil, dehydrated casto...

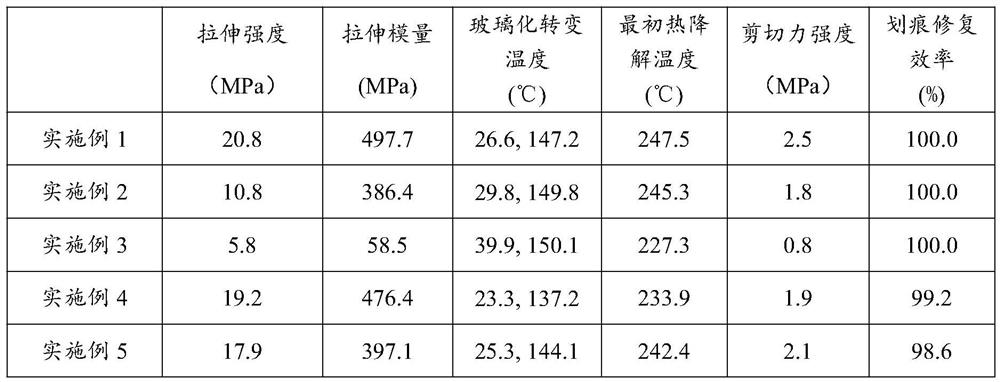

Embodiment 1

[0029] (1) Add castor oil, isophorone diisocyanate (the mol ratio of isophorone diisocyanate and castor oil is 3:1) and catalyzer dibutyltin dilaurate in reactor (catalyst addition is total reaction mass 0.5% of the weight), heated to 50°C for 2h after stirring evenly, to obtain the castor oil-based polyurethane intermediate product CTI;

[0030] (2) Add N,N'-di-tert-butylethylenediamine (the molar ratio of N,N'-di-tert-butylethylenediamine to isophorone diisocyanate is 1:2) into the above reactor, Heating to 20°C for 0.5h, and then subjecting the obtained product to hot pressing (hot pressing temperature 60°C, applied pressure 10MPa, hot pressing time 10min) to obtain castor oil-based polyurethane material HUB1.

Embodiment 2

[0032] (1) Add castor oil, isophorone diisocyanate (the molar ratio of isophorone diisocyanate and castor oil is 4:1), tetraethylene glycol (tetraethylene glycol and isophorone The molar ratio of phorone diisocyanate is 1:8) and the catalyst dibutyltin dilaurate (the amount of the catalyst added is 0.5% of the total weight of the reaction material), stir evenly and heat to 50°C for 2h to obtain castor oil-based polyurethane intermediate Product CTI2;

[0033] (2) Add N,N'-di-tert-butylethylenediamine (the molar ratio of N,N'-di-tert-butylethylenediamine to isophorone diisocyanate is 1:2) into the above reactor, Heated to 20°C for 0.5h, and then subjected to hot pressing (hot pressing temperature 60°C, applied pressure 10MPa, hot pressing time 10min) to obtain castor oil-based polyurethane material HUB2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com