Mixed sealing type top-mounted low-temperature ball valve

A top-mounted and sealed technology, which is applied in the direction of valve details, valve devices, and valve housing structures, can solve the problems of inconvenient gas leakage, wear of rubber sealing rings and sealing packing, and gas leakage, so as to prevent gas leakage and improve The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

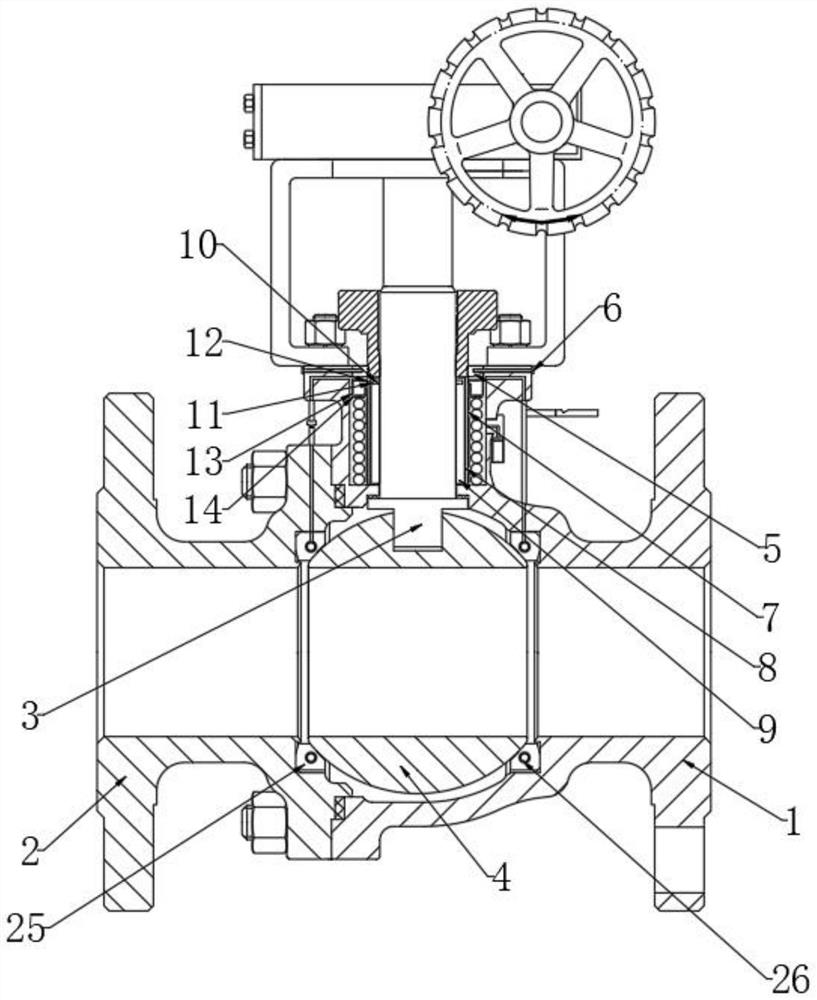

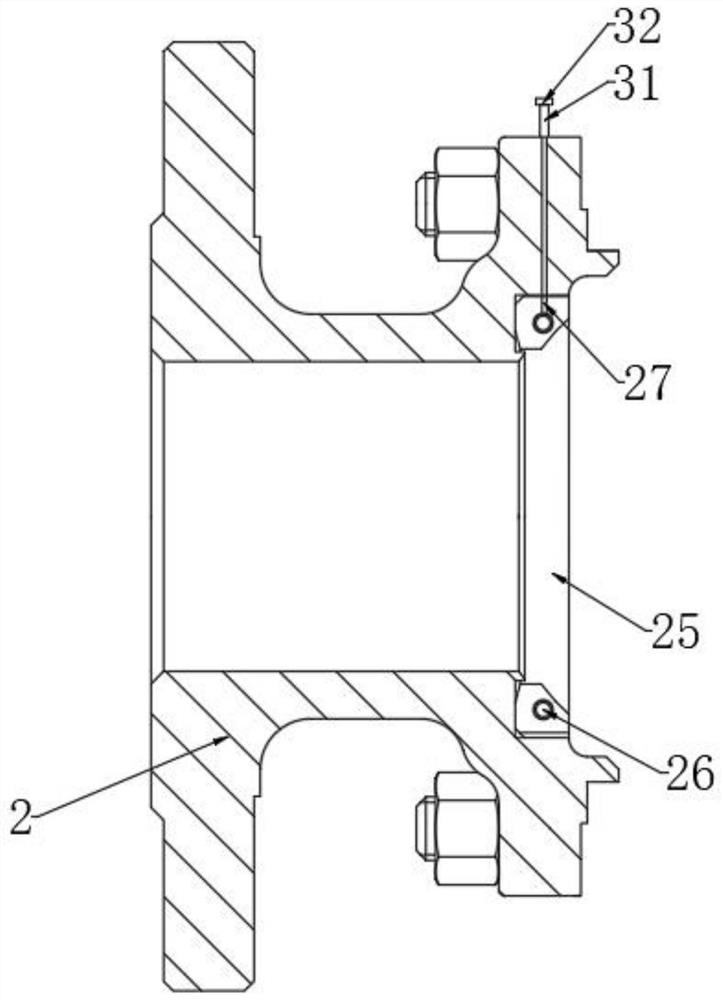

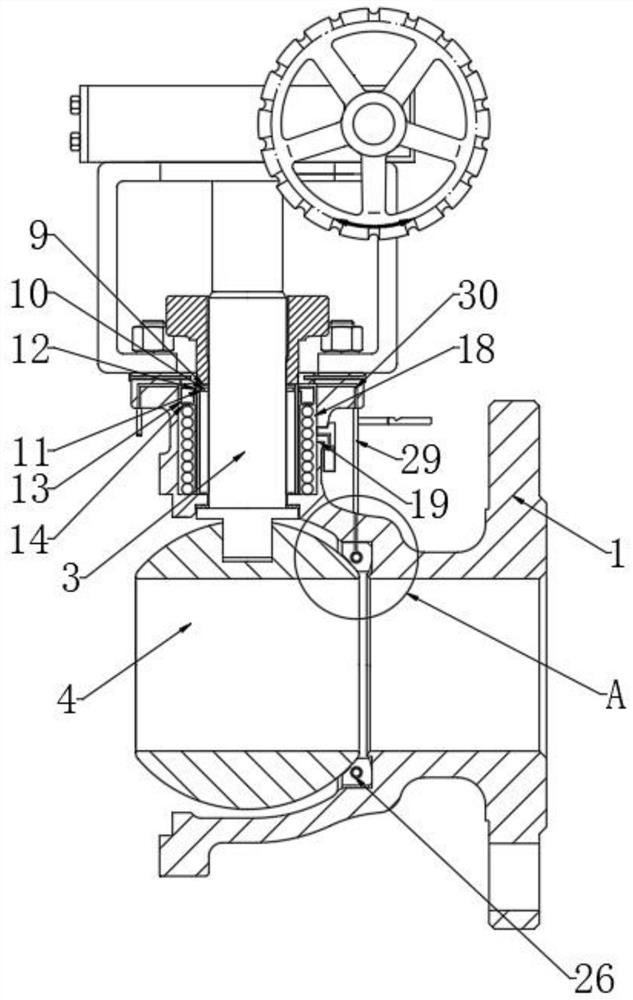

[0041] see figure 1 , 3 And 5-7, a hybrid sealed top-entry cryogenic ball valve, including a valve seat pipe 1, the left end of the valve seat pipe 1 is fixedly connected with a butt pipe 2, the upper end of the valve seat pipe 1 is rotatably connected with a valve stem 3, and the valve stem The lower end of 3 is fixedly connected with shut-off ball 4, and shut-off ball 4 is located in the pipeline inner cavity of valve seat pipe 1, and the upper end of valve seat pipe 1 is embedded with connecting ring 5, and the outer peripheral surface of connecting ring 5 is equipped with bolt 6, and the bolt 6 6. The pipeline 1 through the valve seat is threadedly connected with the connecting ring 5. The lower end of the connecting ring 5 is fixedly connected with the connecting cylinder 7. The connecting cylinder 7 is located on the outside of the valve stem 3. The inner wall of the connecting cylinder 7 is fixedly connected with a deformation memory metal ring 8. The inner wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com