Colorimetric sensor and manufacturing method and application thereof

A technology of colorimetric sensor and manufacturing method, which is applied in the field of chemical analysis, can solve the problems of low sensitivity of hexavalent chromium ions, and achieve the effects of improving detection limit and sensitivity and accelerating aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

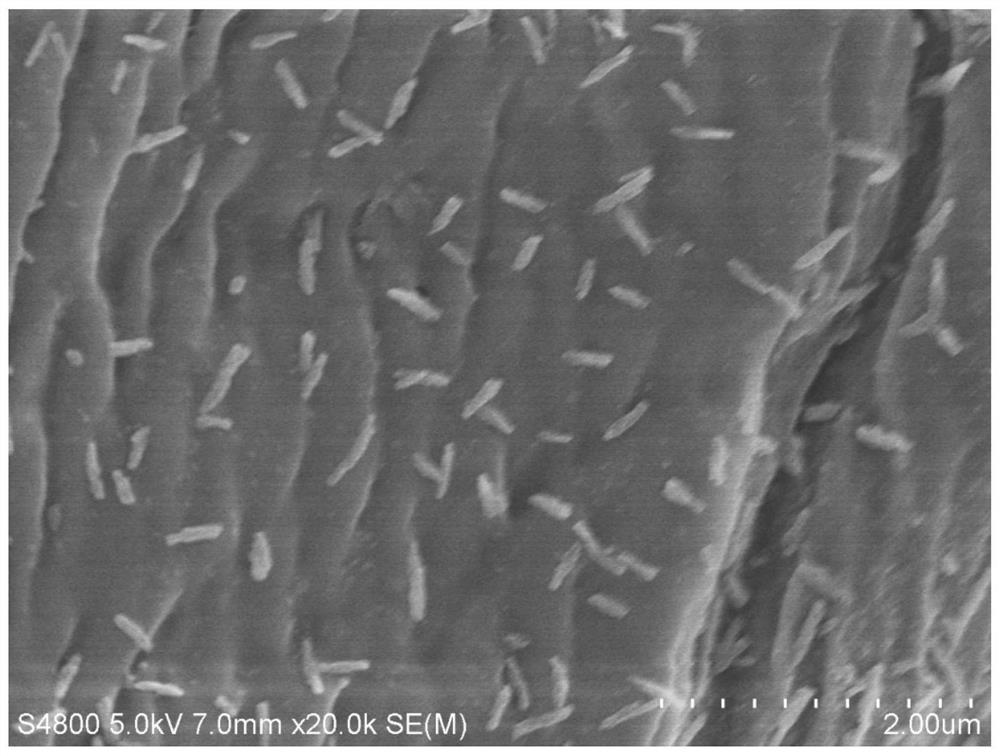

[0051] This embodiment proposes a colorimetric sensor, which is prepared by the following steps:

[0052] S1, soak the cotton cloth in a sodium carbonate solution with a mass fraction of 10% and treat it at 80°C;

[0053] S2, the cotton cloth treated in step S1 is activated in a NaOH solution with a mass fraction of 10% for 12 hours, and the activated cotton cloth is soaked in a solution containing 2,3-epoxypropyltrimethylammonium chloride and NaOH Carry out cationic modification at 90°C for 4h to obtain the modified cotton cloth; The concentration is 0.08g / mL, and the concentration of NaOH is 10%;

[0054] S3. Soak the modified cotton cloth in a diphenylcarbazide solution with a concentration of 6mmol / L at 20°C and shake it for 1 hour to obtain a colorimetric sensor, so that diphenylcarbazide is loaded on the cotton cloth, and then dried , Cut the colorimetric detector into small pieces with a length*width of 0.6cm*0.8cm, and store in a cool and dry place sealed.

[0055] ...

Embodiment 2

[0057] This embodiment proposes a colorimetric sensor, which is prepared by the following steps:

[0058] S1. Soak the cotton cloth in a sodium carbonate solution with a mass fraction of 15% and treat it at 90°C;

[0059] S2, the cotton cloth treated in step S1 is activated in a NaOH solution with a mass fraction of 15% for 15 hours, and the activated cotton cloth is soaked in a solution containing 2,3-epoxypropyltrimethylammonium chloride and NaOH Carry out cationic modification at 80°C for 3h to obtain the modified cotton cloth; The concentration is 0.1g / mL, the concentration of NaOH is 15%;

[0060] S3. Soak the modified cotton cloth in a diphenylcarbazide solution with a concentration of 7mmol / L at 25°C and shake it for 1.5h to obtain a colorimetric sensor, so that diphenylcarbazide is loaded on the cotton cloth, and then Dry, cut the colorimetric detector into small pieces with a length*width of 0.6cm*0.8cm, and store in a cool and dry place sealed.

Embodiment 3

[0062] This embodiment proposes a colorimetric sensor, which is prepared by the following steps:

[0063] S1. Soak the cotton cloth in a sodium carbonate solution with a mass fraction of 12% and treat it at 100°C;

[0064] S2, the cotton cloth treated in step S1 is activated in a NaOH solution with a mass fraction of 12% for 13 hours, and the activated cotton cloth is soaked in a solution containing 2,3-epoxypropyltrimethylammonium chloride and NaOH Carry out cationic modification at 85°C for 5h to obtain the modified cotton cloth; The concentration is 0.09g / mL, and the concentration of NaOH is 12%;

[0065] S3. Soak the modified cotton cloth in a diphenylcarbazide solution with a concentration of 7mmol / L at 25°C and shake it for 2 hours to obtain a colorimetric sensor, so that diphenylcarbazide is loaded on the cotton cloth, and then dried , Cut the colorimetric detector into small pieces with a length*width of 0.6cm*0.8cm, and store in a cool and dry place sealed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com