Method for non-destructively evaluating molar ratio of lithium to cobalt in lithium battery electrode

A lithium-cobalt molar ratio, non-destructive evaluation technology, applied in the field of electrochemical measurement, can solve the problems of cumbersome and inaccurate lithium-cobalt molar ratio measurement, and achieve the effects of less human interference, lower pollution emissions, and lower relative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

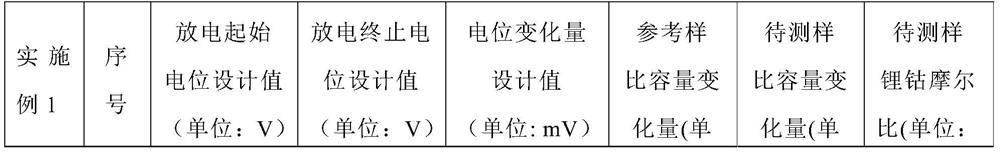

Embodiment 1

[0049] Select a commercially available lithium cobaltate material of a known lithium-cobalt mol ratio as the reference sample marked as M 0 , and at the same time choose the same type of commercially available lithium cobalt oxide material as the sample to be tested, marked as M 1. The above reference sample and the sample to be tested were respectively mixed with the conductive agent Super P and the binder PVDF according to the same mass ratio of 9:0.14:0.2 and the same process conditions to make electrode test sheets and assemble them into button cells. Among them, the buckle specification is CR2023, the positive electrode is lithium cobalt oxide material, the negative electrode is lithium sheet, the diaphragm is polypropylene film, the electrolyte solvent is a mixture of EC / DEC with a volume ratio of 1:1, and the conductive salt is 1M Lithium hexafluorophosphate. The packaging pressure of the buckle is 800Pa, and the packaging time is 5 seconds. The test batteries made o...

Embodiment 2

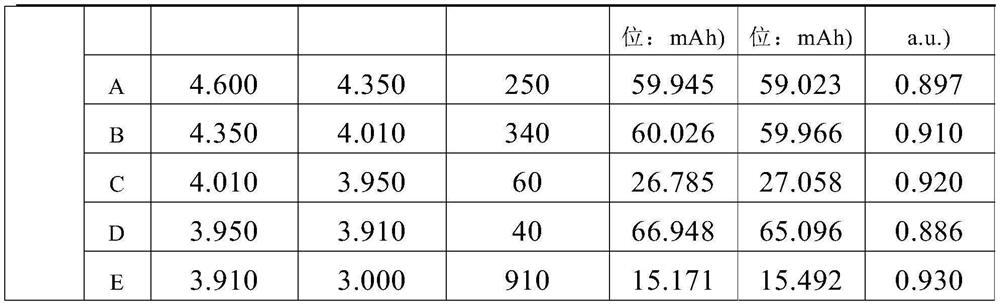

[0056] Continue to use the reference sample battery C in Example 1 0 and the sample battery C to be tested 1 , to collect data during the charging phase, and to measure by combining constant current discharge (CC step) and constant voltage discharge (CV step). Among them, the charging current of constant current charging (CC working step) is represented by a multiplier, which is set to 0.1C, and the duration of constant voltage charging (CV working step) is set to 1 hour. Repeat the CC-CV steps until the potential of the test battery approaches the charge cut-off potential of 4.60V, and the reference battery C is at the same steady-state potential during the recording process. 0 and the battery under test C 1 change in specific capacity. According to the ratio of the specific capacity change of the reference battery and the battery under test at the same potential and the lithium-cobalt molar ratio of the reference sample, calculate the lithium-cobalt molar ratio of the lit...

Embodiment 3

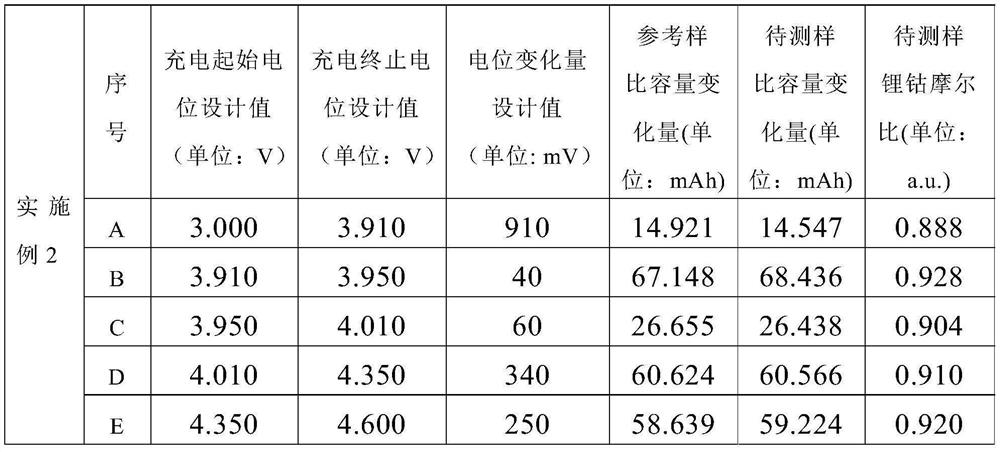

[0060] Continue to use the reference sample battery C in Example 1 0 and the sample battery C to be tested 1 , Repeat the data collection in the discharge stage, and use the combination of constant current discharge (CC step) and constant voltage discharge (CV step) to measure. Wherein the design start potential and end potential of each stage are the same as in Example 1, and the constant current discharge rate and the holding time of the constant voltage discharge stage are changed in each stage, and the specific design values are shown in the table below. Repeat the CC-CV steps until the potential of the test battery approaches the discharge cut-off potential of 3.0V, and the reference battery C is at the same steady-state potential during the recording process. 0 and the battery under test C 1 change in specific capacity. According to the ratio of the specific capacity change of the reference battery and the battery under test at the same potential and the lithium-cob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com