A utg-qd type mini-led board and its application, preparation method and optical structure

A UTG-QD and LED lamp technology, applied in the field of materials, can solve the problems of low optical utilization rate of LED lamp beads, affect the life and effect of backlight, affect the thickness and appearance of the whole machine, etc., so as to improve the light utilization rate and improve the overall contrast , novel appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

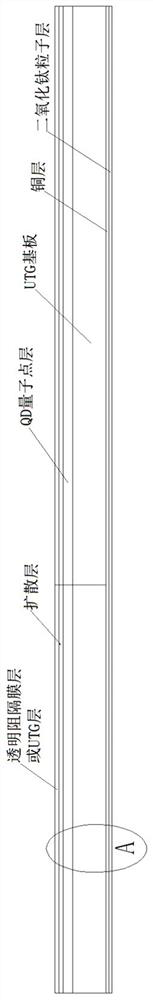

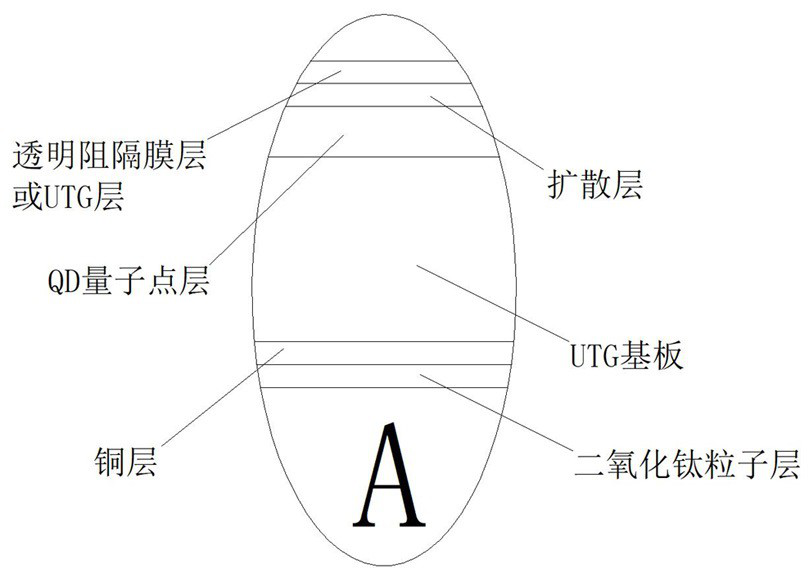

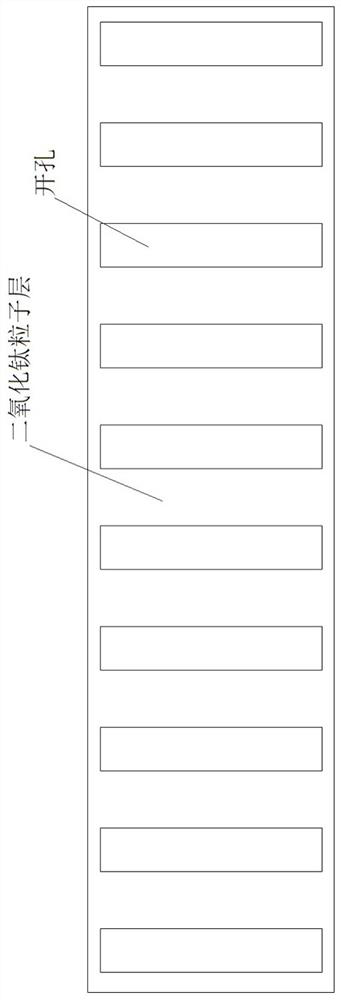

[0060] as attached figure 1 , attached figure 2 And attached image 3 As shown, this embodiment discloses a UTG-QD type MINI-LED board, including a UTG substrate with a flat surface, and a QD quantum dot layer evenly coated on the upper surface of the UTG; a layer of copper is plated on the light incident surface of the UTG substrate layer, the outer surface of the copper layer is coated with a titanium dioxide particle layer, the QD quantum dot layer is covered with a diffusion layer, and a transparent barrier film layer is adhered to the diffusion layer. The copper layer and the titanium dioxide particle layer are provided with openings matching the size of the light emitting surface of the blue LED lamp, and the copper layer is etched with control circuits.

[0061] Wherein, the thickness of the QD quantum dot layer is 30-150 μm.

[0062] The refractive index of the diffusion layer is 1.365-1.455 or 1.5103-1.635, and the thickness is 50-120 μm.

[0063] The thickness ...

Embodiment 2

[0067] as attached figure 1 , attached figure 2 And attached image 3 As shown, this embodiment discloses a UTG-QD type MINI-LED board, including a UTG substrate with a flat surface, and a QD quantum dot layer evenly coated on the upper surface of the UTG; a layer of copper is plated on the light incident surface of the UTG substrate layer, the outer surface of the copper layer is coated with a titanium dioxide particle layer, the QD quantum dot layer is covered with a diffusion layer, and the diffusion layer is covered with a UTG layer. The copper layer and the titanium dioxide particle layer are provided with openings matching the size of the light emitting surface of the blue LED lamp, and the copper layer is etched with control circuits.

[0068] Wherein, the thickness of the QD quantum dot layer is 30-150 μm.

[0069] The refractive index of the diffusion layer is 1.365-1.455 or 1.5103-1.635, and the thickness is 50-120 μm.

[0070] The thickness of the UTG layer is...

Embodiment 3

[0074] as attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 As shown, this embodiment discloses a UTG-QD type MINI-LED board. The UTG substrate uses UTG as the base material, and the light-emitting surface of the UTG substrate is evenly arrayed with several micron-scale inverted tapered grooves of the same size. . The depth of the inverted tapered grooves is 10-50 μm; the horizontal distance between the center points of two adjacent inverted-tapered grooves is 50-200 μm; the taper angle of the inverted tapered grooves is 60° or 90°. The light-emitting surface of the UTG substrate is uniformly coated with a QD quantum dot layer with a thickness of 30-150 μm. The QD quantum dot layer is covered with a diffusion layer, and a transparent barrier film layer is bonded to the diffusion layer. QD quantum dots. A layer of copper is plated on the light incident surface of the UTG substrate, and a layer of titanium dioxide particles is coated on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com