Fuel cell catalyst with high-density active sites and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, limited slow kinetics, insufficient catalyst performance and durability, etc., to accelerate oxygen reduction kinetics, improve interaction Force, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

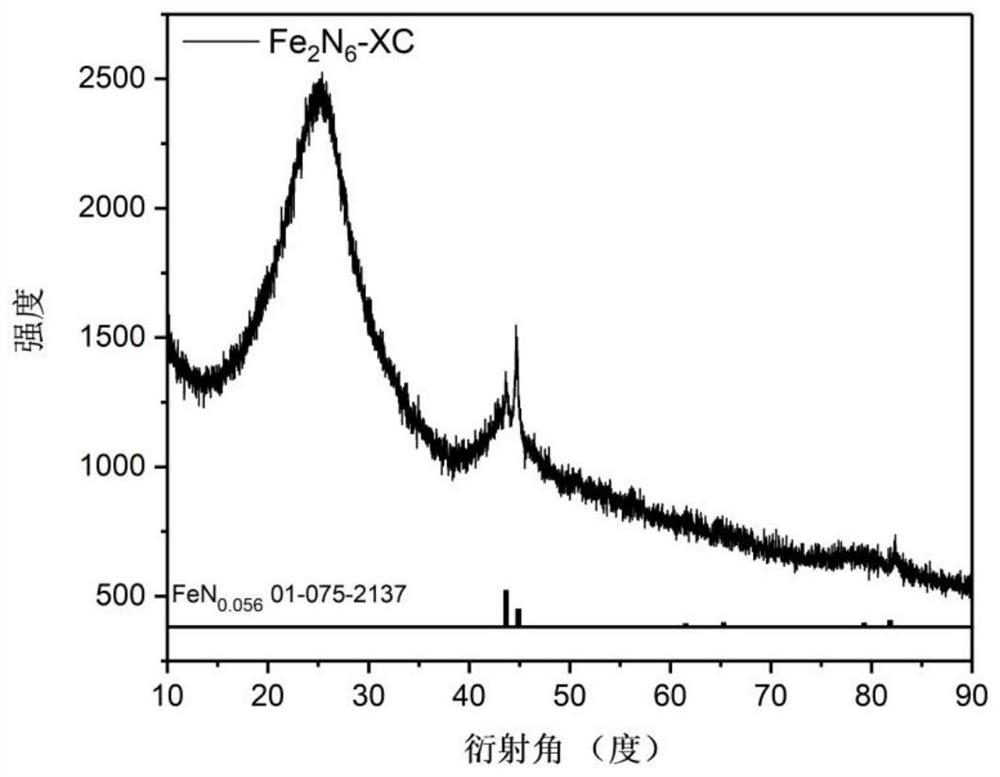

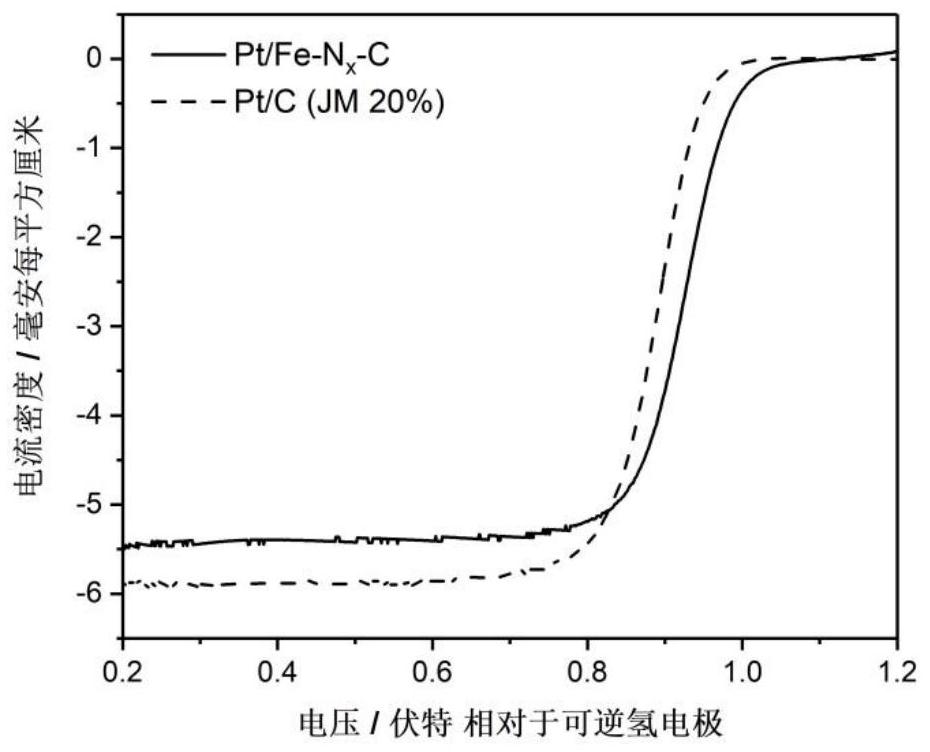

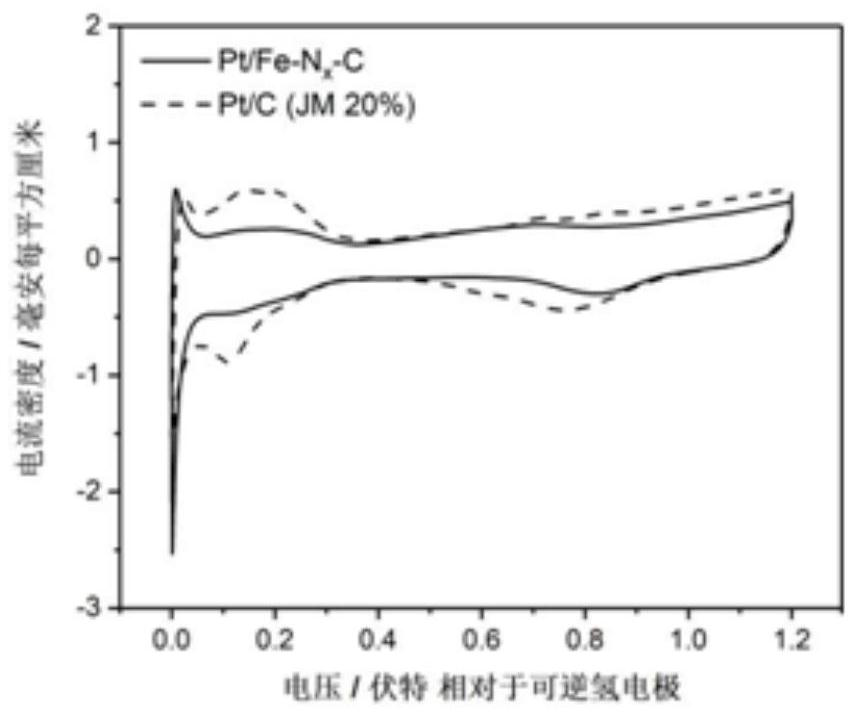

[0040] First, put 1g of Ketjen Black EC-600 in a tube furnace under an ammonia atmosphere and calcined at 850°C for 1h. After the calcining, cool to room temperature, grind and collect; Ketjen Black EC-600 high specific surface area carbon was added to deionized water for ultrasonication and stirred overnight; the stirred solution was freeze-dried and collected; the collected powder was calcined in a tube furnace at 600°C for 2 hours in an argon atmosphere , after calcination, a carbon-based Fe-N with highly dense active sites was obtained x -C. After that, take 40 mg carbon substrate Fe-N x -C, 4.4 mg H 2 PtCl 6 ·6H 2 O was added to 20ml of ethylene glycol (EG), and stirred continuously for 2h in an oil bath at 120°C. After the oil bath was completed, the product was centrifuged and washed several times with ultrapure water, and dried overnight at 60° C. under vacuum to obtain a catalyst loaded with Pt nanoparticles.

Embodiment 2

[0042]First, put 1g of Ketjen Black EC-600 in a tube furnace under an ammonia atmosphere and calcined at 900°C for 1h. After the calcining, cool to room temperature, grind and collect it; Ketjen Black EC-600 high specific surface area carbon was added to deionized water for ultrasonication and stirred overnight; the stirred solution was freeze-dried and collected; the collected powder was calcined in a tube furnace at 700°C for 2 hours in an argon atmosphere , after calcination, a carbon-based Fe-N with highly dense active sites was obtained x -C. After that, take 40 mg carbon substrate Fe-N x -C, 4.4 mg H 2 PtCl 6 ·6H 2 O was added to 20ml of ethylene glycol (EG), and stirred continuously for 3h in an oil bath at 120°C. After the oil bath was completed, the product was centrifuged and washed several times with ultrapure water, and dried overnight at 60° C. under vacuum to obtain a catalyst loaded with Pt nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com