Polyimide-Based Catalytic Cathodic Carbon Membrane Supporting Single Atom Catalyst and Its Application

A polyimide-based and polyimide precursor technology, applied to polyimide-based catalytic cathode carbon membranes loaded with single-atom catalysts and its application fields, can solve the problem that single-atom catalysts are prone to agglomeration and difficult to recycle for a long time , collection difficulties and other problems, to achieve the effect of solving the low utilization rate of metal atoms, reducing the resistance of electron transfer, and realizing electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method comprises the following steps:

[0038] 1) Preparation of ZnM-BMOFs: the target metal M salt methanol solution and Zn 2+ Mix the salt methanol solution with the 2-methylimidazole organic ligand methanol solution, adjust the pH, mix and dissolve with ultrasound and stir, after drying for 4 hours, the precipitate is washed with methanol solution, and then dried at 70-80°C;

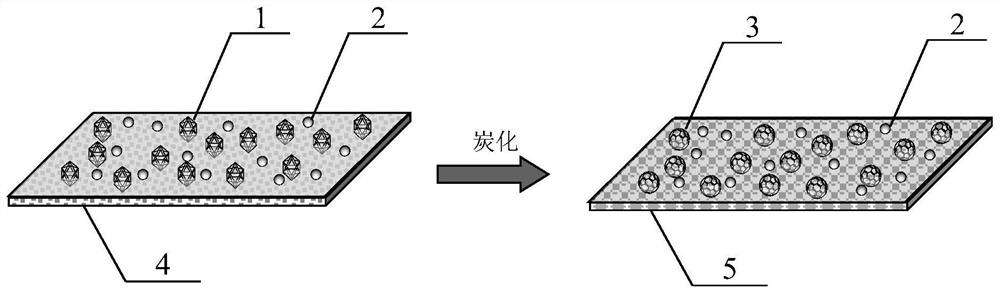

[0039] 2) Preparation of ZnM-BMOFs / carbon nanotubes / polyamic acid hybrid film: ultrasonically disperse the ZnM-BMOFs powder and carbon nanotube powder prepared in step 1) into N,N-dimethylacetamide solvent, Prepare solution A for later use; dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide solvent, and stir until 4,4'-diaminodiphenyl ether is completely dissolved, and then add Add pyromellitic dianhydride to the solution several times to completely dissolve pyromellitic dianhydride to obtain prepolymer polyamic acid solution B; mix solution A and solution B evenly, s...

Embodiment 1

[0048] 1. Preparation of the target metal Co single-atom catalyst / carbon nanotube / polyimide-based catalytic carbon membrane:

[0049] 1) Take 1.86g of Zn(NO 3 ) 2 ·6H 2 O and 1.455g of Co(NO 3 ) 2 ·6H 2 Dissolve O in 50mL of methanol solution, shake to dissolve; dissolve 2.05g of 2-methylimidazole in 50mL of methanol solution, dissolve and mix well. Then add the prepared metal salt mixed solution into the organic ligand methanol solution, and ultrasonically dissolve it for 15 minutes, and stir for 12 hours; the obtained mixed solution is placed in an oven at 120 ° C for 4 hours, and the precipitate cooled to room temperature is centrifuged, and then used Wash with methanol for 3-5 times, and finally dry at 70°C for 8 hours to obtain the ZnCo-BMOFs material.

[0050] 2) Disperse 1g of ZnCo-BMOFs powder and 1g of carbon nanotube powder into 10mL of N,N-dimethylacetamide solvent, stir magnetically for 2h, and disperse ultrasonically for 2h to prepare solution A for later us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com