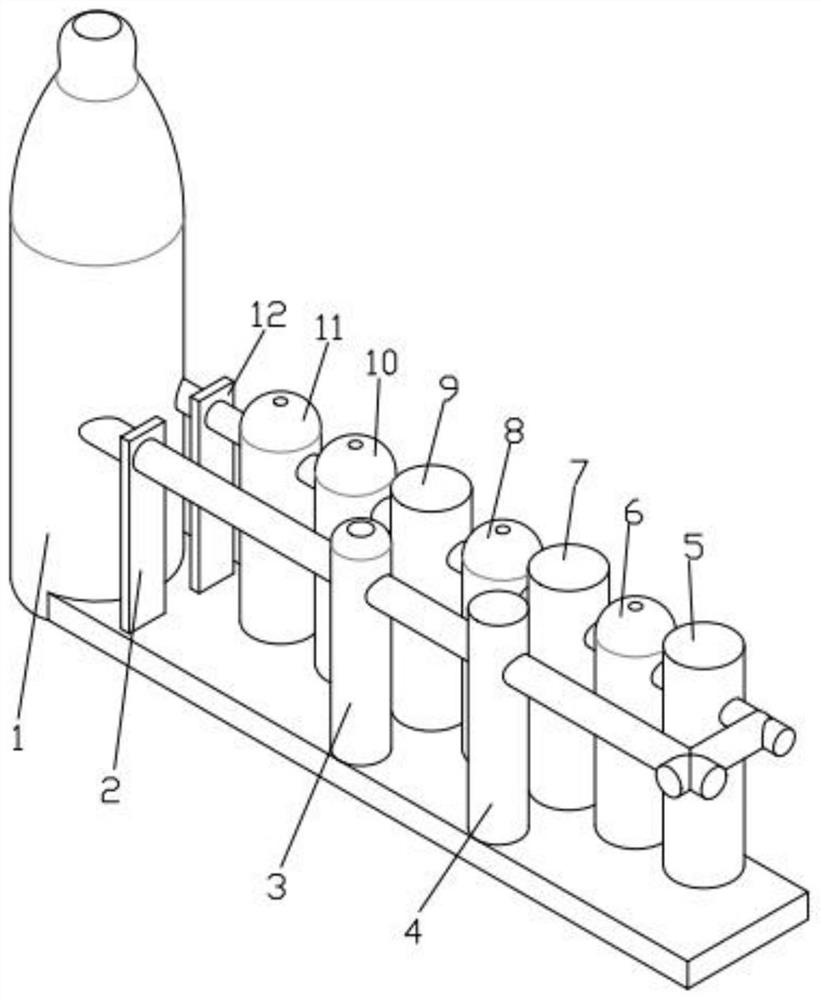

Supercritical fluid extraction device and method and application

A supercritical fluid and extraction device technology, applied in solid solvent extraction, separation methods, solvent extraction, etc., can solve the problems of unqualified purity of extracts, low extraction rate of general products, and low extraction rate, so as to increase the extraction rate of products , less energy consumption and low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the embodiments. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

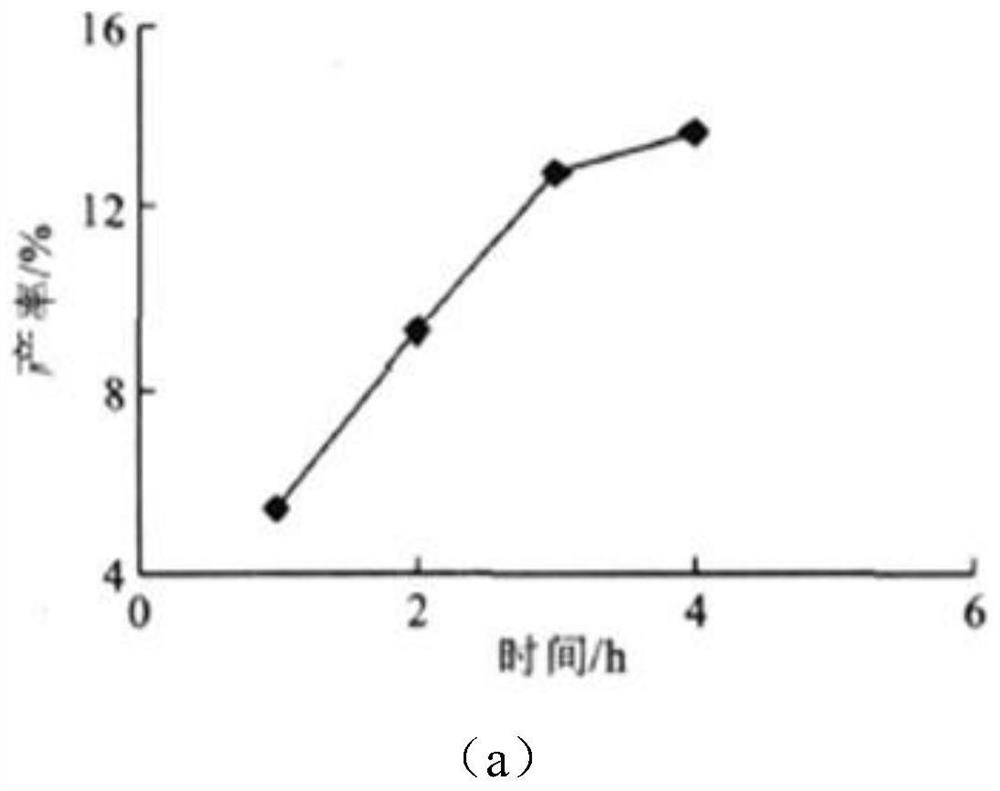

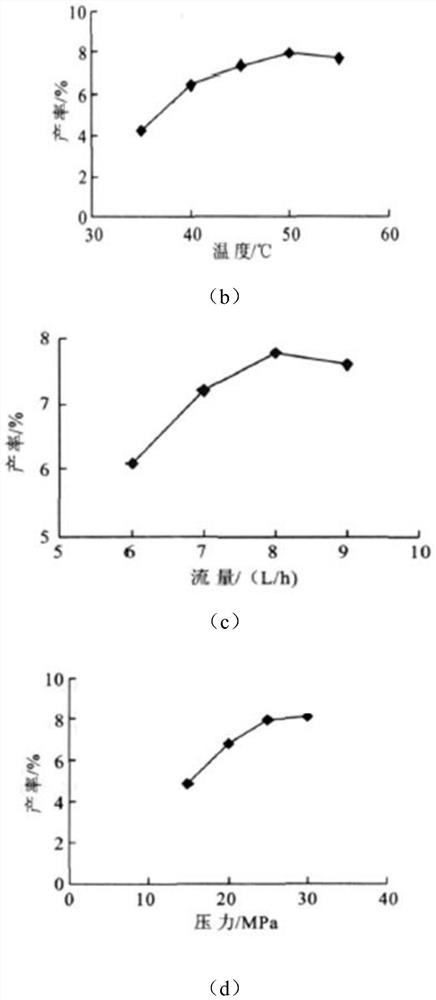

[0026] Aiming at the product extraction rate of the conventional extraction, the purity of the extract is unqualified; the extraction solvent is toxic; the extraction and separation of the invention is one, the extraction efficiency is high, and the energy consumption is small, cost savings, and conformity The trend of environmentally friendly energy saving. You can view the workload in production, so that your work is planned. The closure of the line can be controlled, and the extraction process can be sufficiently performed, increase the product extraction rate, and the purity of the extract.

[0027] The application principle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap