Production method and equipment of thermal insulation and decoration integrated plate with building envelope and product

A technology of enclosure structure and production method, which is applied to auxiliary molding equipment, supply device, unloading device, etc., can solve the problems of poor water resistance, inability to prevent the spread of fire in the barrier system, and decrease in strength of the integrated thermal insulation and decoration board. Fire performance and safety factor, the achievement of structural fire rating performance, the effect of retarding the rapid spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

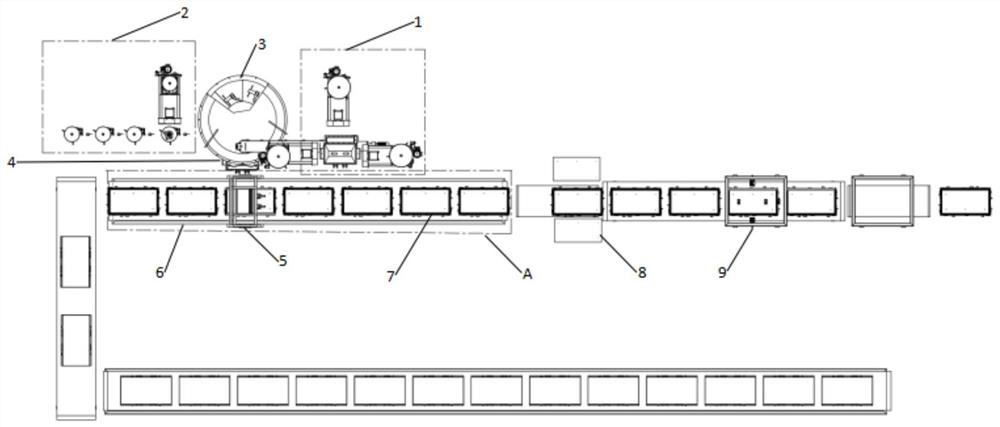

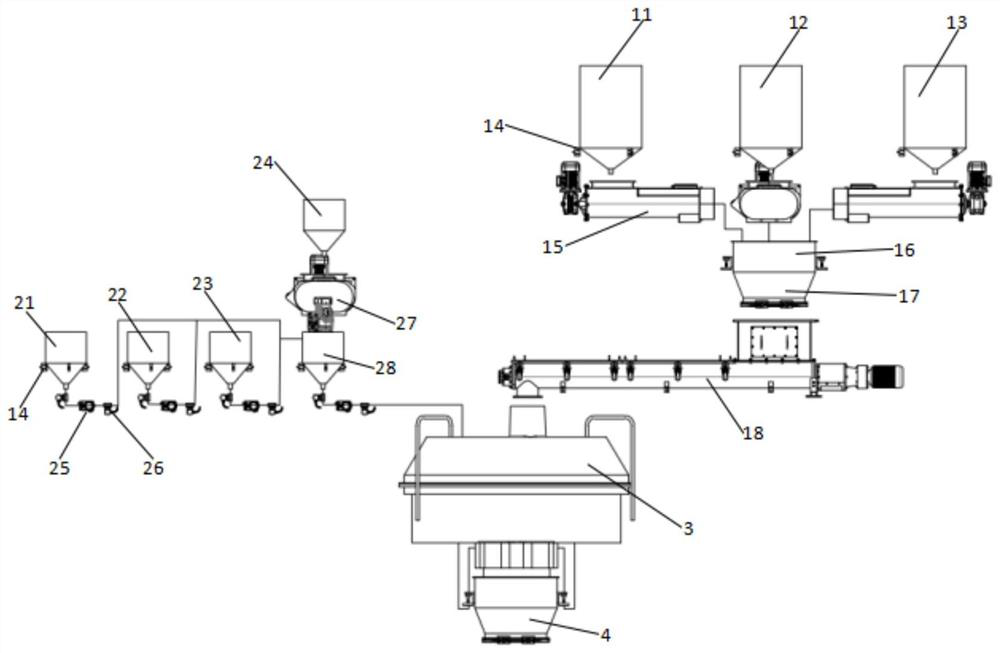

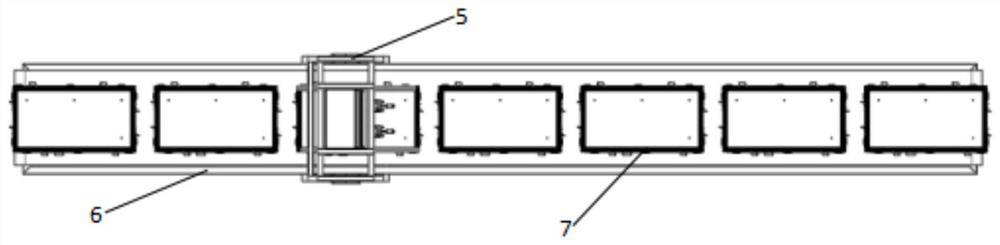

[0060] This embodiment provides a production equipment for thermal insulation and decoration integrated panels with an enclosure structure, which specifically includes a slurry preparation system, a transmission system, a distribution system, a molding system, and a curing and maintenance system.

[0061] As a further improvement, the slurry preparation system includes a powder feeding device 1 and a liquid feeding device 2, wherein the powder feeding device 1 and the liquid feeding device 2 are connected to a stirring device 3, and the stirring device 3 is connected to the slurry Active tank 4 is connected.

[0062] In the specific implementation process, the powder material feeding device 1 includes a first powder material tank 11, a second powder material tank 12 and a third powder material tank 13, which are respectively used to store solid aggregate sandstones of different finenesses, three Load cells 14 are respectively arranged on the side walls of the powder tanks, and...

Embodiment 2

[0073] This embodiment provides a production method of a five-sided thermal insulation and decoration integrated panel with an enclosure structure, that is, an thermal insulation and decoration integrated panel with an exposed core material on the upper surface, which specifically includes the following steps:

[0074] (1) Prepare the slurry flow concrete, place the slurry flow concrete mixed by the mixer in the distributing machine for standby, the specific process is as follows:

[0075] The slurry flow concrete includes: 80 parts of white Portland cement, 10 parts of mineral powder, 10 parts of white metakaolin, 20 parts of 60-80 mesh fine quartz sand, 30 parts of 40-70 mesh quartz sand, 10-40 mesh coarse 50 parts of quartz sand, 5 parts of red pigment, 3 parts of polycarboxylate superplasticizer, 23 parts of water, 2 parts of alkali-resistant glass fiber.

[0076] The preparation process includes, pre-mixing fine aggregate and coarse aggregate in a planetary mixer, then mi...

Embodiment 3

[0085] This embodiment provides a production method of a six-sided thermal insulation and decoration integrated panel with an enclosure structure, that is, the thermal insulation core material is completely wrapped in the solidified slurry flow dynamic concrete, which specifically includes the following steps:

[0086] (1) Prepare the slurry flow concrete, place the slurry flow concrete mixed by the mixer in the distributing machine for standby, the specific process is as follows:

[0087] The slurry flow concrete includes: 80 parts of white Portland cement, 10 parts of mineral powder, 10 parts of white metakaolin, 20 parts of 60-80 mesh fine quartz sand, 30 parts of 40-70 mesh quartz sand, 10-40 mesh coarse 50 parts of quartz sand, 5 parts of red pigment, 3 parts of polycarboxylate superplasticizer, 23 parts of water, 2 parts of alkali-resistant glass fiber.

[0088] The preparation process includes, pre-mixing fine aggregate and coarse aggregate in a planetary mixer, then mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com