Silicone rubber composite material as well as preparation method and application thereof

A technology of composite materials and silicone rubber, which is applied in the direction of rubber insulators, rubber layered products, chemical instruments and methods, etc., can solve the problems of low strength, achieve the effects of increasing compactness, avoiding early curing, and good puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

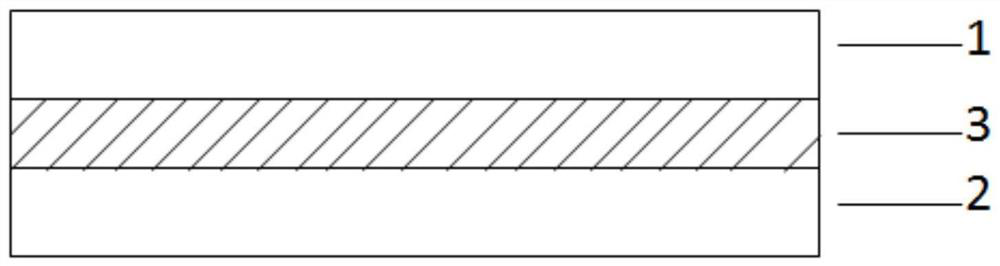

[0071] This example prepares a kind of silicone rubber composite material, structure such as figure 1 as shown, figure 1 Among them, 1 is the first silicone rubber mastic layer, 2 is the second silicone rubber mastic layer, and 3 is the reinforcement layer. The concrete steps of preparation are:

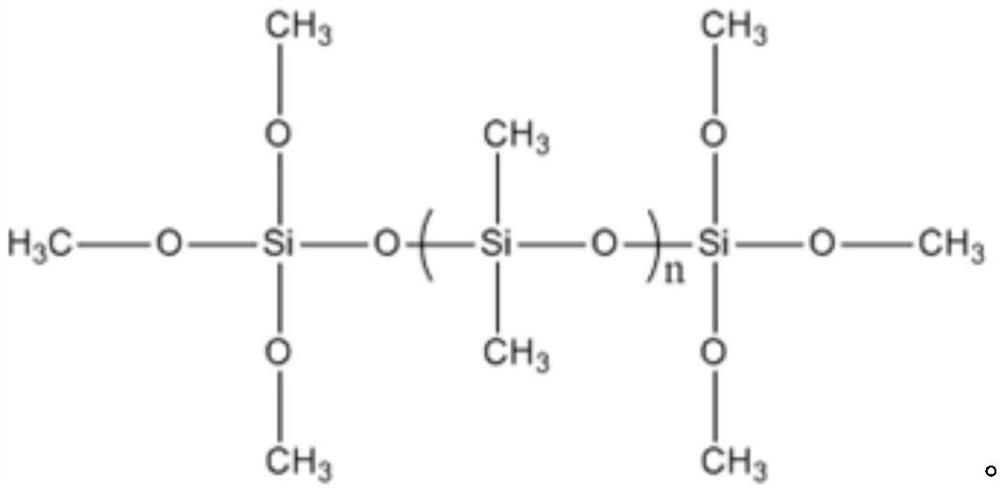

[0072] Add 100kg of trialkoxy-terminated polydimethylsiloxane with a viscosity of 150000mP·s into the vacuum kneader, and then add 25kg of it with a specific surface area of 120mP 2 / g of hydrophobic fumed silica, 42kg of active light calcium carbonate, 35kg of decabromobiphenyl and 2kg of simethicone oil with a viscosity of 5000mPa·s, mixed at 70°C for 1 hour.

[0073] Turn on the vacuum until the pressure inside the kneader is -0.098MPa, continue kneading for 1.5 hours, then raise the temperature to 125°C, and continue kneading until the Mooney viscosity of the rubber compound in the kneader reaches 15 (55°C, 1+4min).

[0074] Cool the mixed rubber to below 60°C, add 2.5kg met...

Embodiment 2

[0078] This embodiment has prepared a kind of silicone rubber composite material, and the concrete steps of preparation are:

[0079] Add 100kg of trialkoxy-terminated polydimethylsiloxane with a viscosity of 200000mP·s into the vacuum kneader, and then add 20kg of it with a specific surface area of 240mP 2 / g of hydrophobic fumed silica, 35kg of active light calcium carbonate, 35kg of decabromobiphenyl and 2kg of simethicone oil with a viscosity of 5000mPa·s were kneaded at 80°C for 1.5 hours.

[0080] Turn on the vacuum until the pressure inside the kneader is -0.098MPa, continue kneading for 1.5 hours, then raise the temperature to 125°C, and continue kneading until the Mooney viscosity of the rubber compound in the kneader reaches 15 (55°C, 1+4min).

[0081] Cool the mixed rubber to below 60°C, add 2.0kg of methyltrimethoxysilane, 1.6kg of 3-(2,3-epoxypropoxy)propyltrimethoxysilane and 1.5kg of kg of tetra-n-butyl titanate, after kneading at 55°C for 1 hour, the Mooney ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com