A anti-torsion and anti-fatigue long-life wind power cable and its preparation method

An anti-fatigue, long-life technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of being susceptible to acid and alkali corrosion, weak heat resistance and insulation performance, and easy to age, and has good market application prospects. , easy to achieve, not easy to open the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

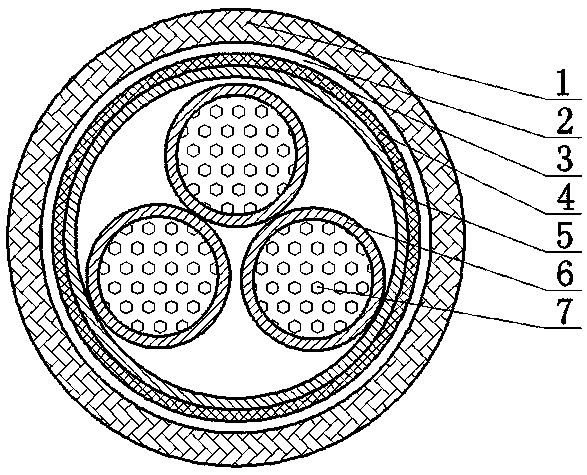

[0028] A anti-torsion and anti-fatigue long-life wind power cable, characterized in that the cable is sequentially provided with a high-strength layer 1, a support layer 4, an inner lining 5, an insulating layer 6 and a conductor 7 from the outside to the inside, and the high-strength layer 1 and the support layer 4 is also provided with a toughening layer 2, and the junction of the toughening layer 2 and the support layer 4 is provided with a nylon PA66 layer 3 solidified with a polyvinyl chloride mastic with a mass ratio of 15wt% by nylon PA66 mass; the high-strength layer 1 is formed by a diameter Copper wire with a diameter of 0.05mm-0.2mm, silicon carbide ceramic fiber with a diameter of 0.2mm-0.5mm, and PP flat wire are evenly mixed according to the mass ratio of 1:5:75, and then sealed with vulcanized rubber; support Layer 4 is made of graphitized carbon fiber; toughened layer 2 is made of polyvinyl chloride cement and condensed single-component room temperature vulcaniz...

Embodiment 2

[0046] The whole is consistent with Example 1, the difference is:

[0047] A anti-torsion and anti-fatigue long-life wind power cable, characterized in that the cable is sequentially provided with a high-strength layer 1, a support layer 4, an inner lining 5, an insulating layer 6 and a conductor 7 from the outside to the inside, and the high-strength layer 1 and the support layer 4 is also provided with a toughening layer 2, and the junction of the toughening layer 2 and the support layer 4 is provided with a nylon PA66 layer 3 solidified with a polyvinyl chloride mastic with a mass ratio of 12wt% by nylon PA66 mass; the high-strength layer 1 is formed by a diameter 0.2mm copper wire, silicon carbide ceramic fiber with a diameter of 0.5mm, and PP flat wire are uniformly mixed at a mass ratio of 1:3.5:90, and then sealed with vulcanized rubber; the support layer 4 is made of graphitized carbon fiber Made; the toughened layer 2 is formed by mixing polyvinyl chloride cement and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com