An easy-to-shape cement-based joint sealant for assembly-type component installation and its construction method

A cement-based, installation-use technology, applied in building construction, construction, etc., can solve problems such as construction quality problems, and achieve the effects of fast construction, improved viscosity, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

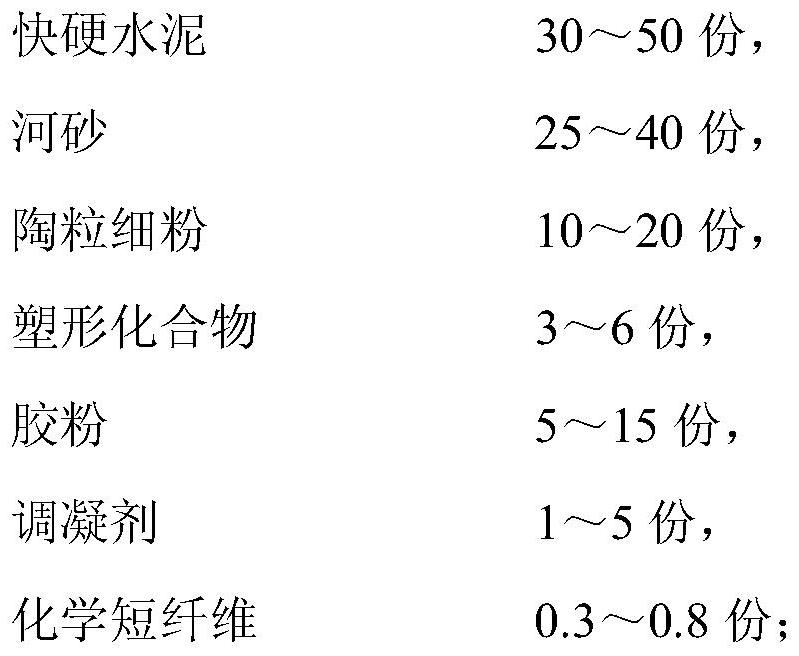

[0033] An easy-to-shape cement-based joint sealant for the installation of prefabricated components, which is mixed with the following components by weight:

[0034]

[0035] Among them, river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:2; ceramsite fine powder is a mixture of 0-0.15mm and 0.15-0.3mm ceramsite with a mass ratio of 1:4; The plastic compound is a mixture of sodium lignosulfonate water reducer, diuterene, and silica fume at a weight ratio of 1:2:4; the rubber powder is redispersible vinyl acetate / ethylene copolymer rubber powder.

Embodiment 2

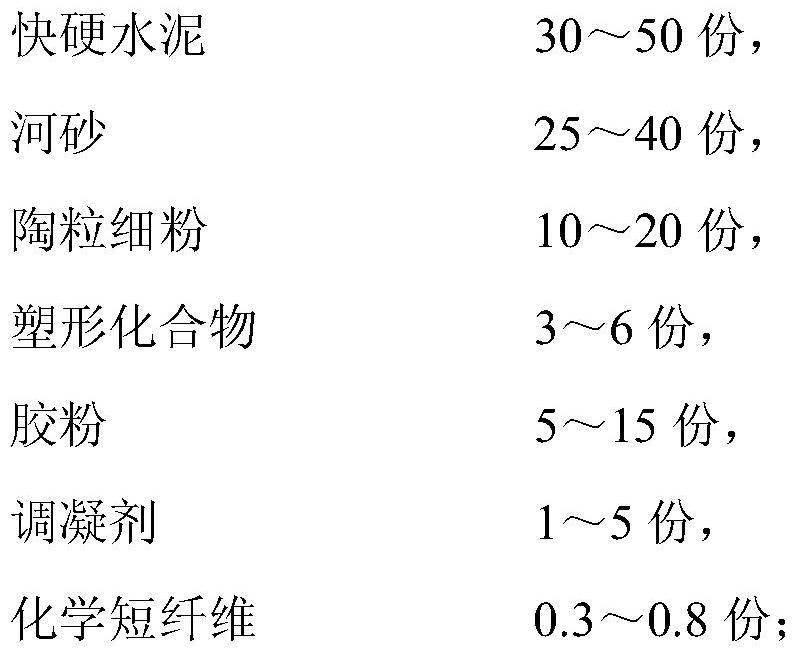

[0037] An easy-to-shape cement-based joint sealant for the installation of prefabricated components, which is mixed with the following components by weight:

[0038]

[0039]

[0040] Among them, the river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:2; the ceramsite fine particles are a mixture of 0-0.15mm and 0.15-0.3mm ceramsite with a mass ratio of 1:3; The plastic compound is a mixture of sodium lignosulfonate water reducer, diuterene, and silica fume at a weight ratio of 1:2:4; the rubber powder is redispersible vinyl acetate / ethylene copolymer rubber powder.

Embodiment 3

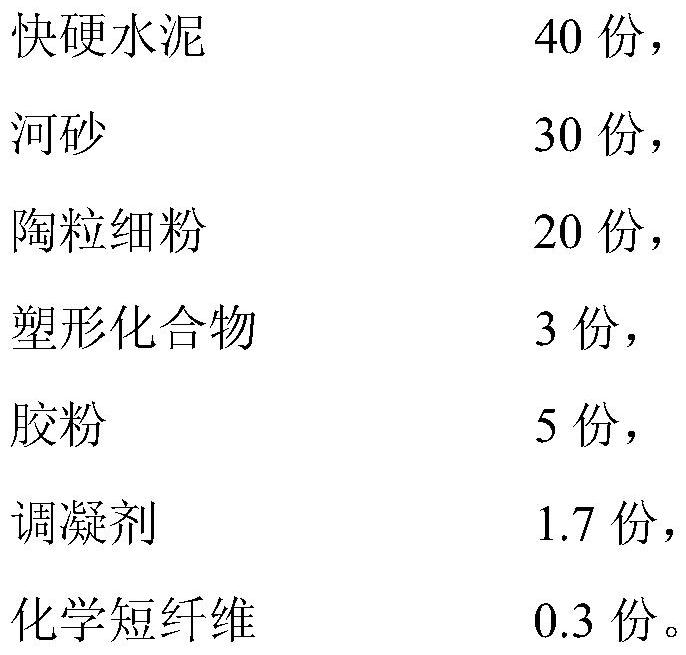

[0042] An easy-to-shape cement-based joint sealant for the installation of prefabricated components, which is mixed with the following components by weight:

[0043]

[0044] Among them, river sand is a mixture of 0-0.3mm and 0.3-0.6mm river sand with a mass ratio of 1:3; ceramsite fine particles are a mixture of 0-0.15mm and 0.15-0.3mm ceramsite with a mass ratio of 1:2; The plastic compound is a mixture of sodium lignosulfonate water reducer, diuterene, and silica fume at a weight ratio of 1:2:4; the rubber powder is acrylic polymer powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com