Chitosan copolymer as well as preparation and application thereof

A chitosan copolymer, chitosan technology, applied in descaling and water softening, chemical instruments and methods, special treatment targets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

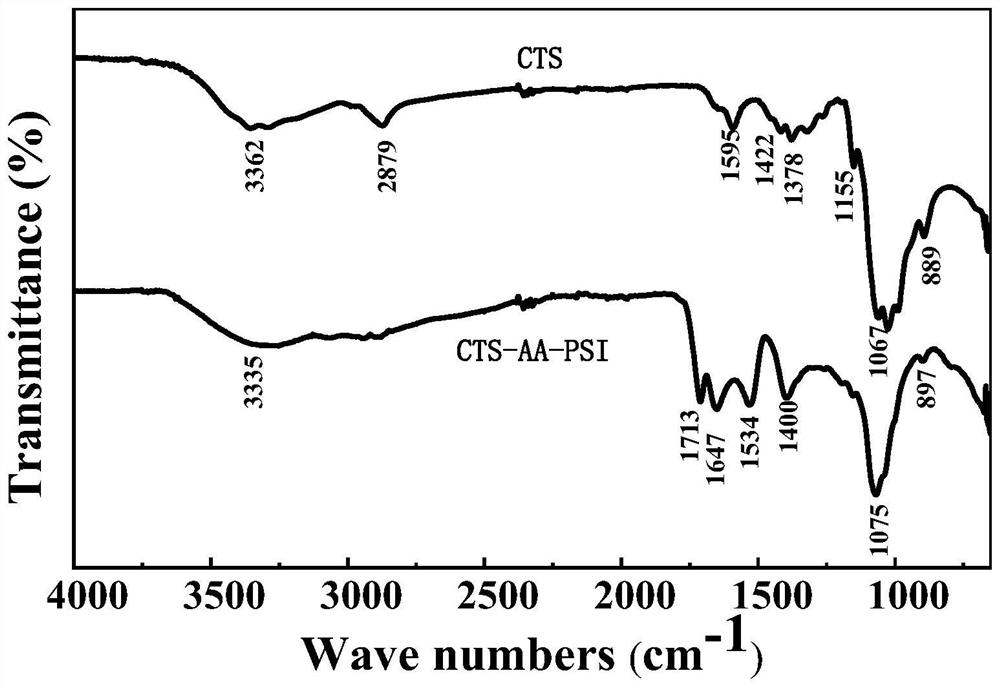

Image

Examples

preparation example Construction

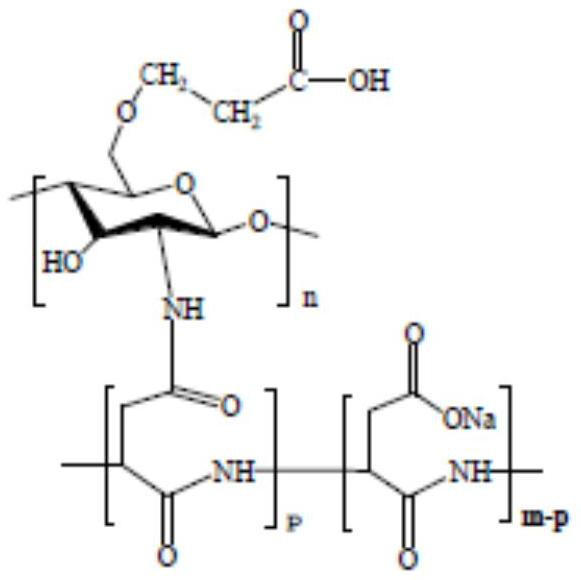

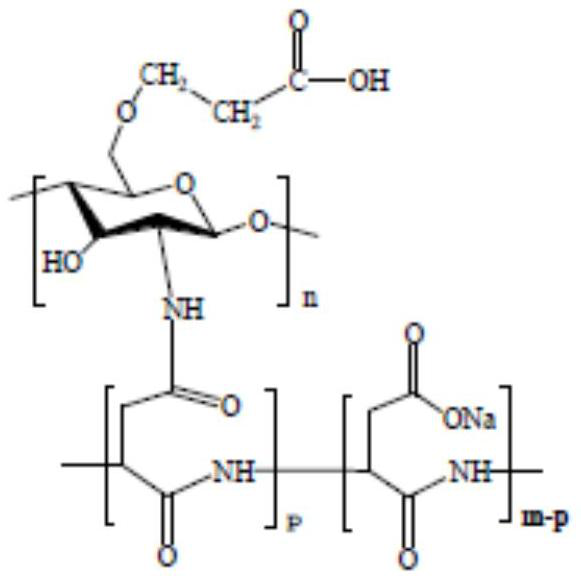

[0032] The preparation method of chitosan-acrylic acid-aspartic acid provided by the invention, its concrete method steps are as follows:

[0033] (1) Synthesis of chitosan-benzaldehyde Schiff base (CTS-BE):

[0034] Add CTS (0.02M) and 100mL distilled water in the three-necked flask, and 2 Under protection, benzaldehyde ethanol solution (0.02M) was added dropwise to the flask, and stirred at 60°C for 12h. The formed pale yellow precipitate was washed three times with distilled water, and dried in a vacuum oven at 60°C for 24 hours to obtain chitosan-benzaldehyde Schiff base, and the reaction equation was as follows:

[0035]

[0036] (2) Synthesis of chitosan-acrylic acid copolymer (O-CTS-AA):

[0037] Chitosan-benzaldehyde (0.01 M) and 0.1 g of ammonium persulfate were dissolved in 100 mL of acetic acid solution (1%). Under the protection of nitrogen, the mixture was stirred at 80°C for 0.5h, then a certain amount of acrylic acid (AA) solution was added dropwise, the m...

Embodiment 1

[0050] A kind of preparation method of chitosan copolymer water treatment agent, comprises the steps:

[0051] Weigh 3.2g of chitosan, measure 100mL of distilled water in a three-neck flask, add 2.1g of benzaldehyde-ethanol solution dropwise to the flask under nitrogen protection, and stir at 60°C for 12h. The formed pale yellow precipitate was washed three times with distilled water, and dried in a vacuum oven at 60° C. for 24 h to obtain chitosan-benzaldehyde Schiff base. 2.66g of chitosan-benzaldehyde and 0.1g of ammonium persulfate were dissolved in 100mL of 1% acetic acid solution. Under the protection of nitrogen, the mixture was stirred at 80° C. for 0.5 h, then 2.16 g of acrylic acid solution was added dropwise, and the reaction was continued for 6 h. The product was precipitated with 200 mL of acetone, the precipitate was washed with absolute ethanol and filtered three times, and dried at 60 °C for 1 h to obtain O-carboxyethyl-benzaldehyde chitosan Schiff base. Acid...

Embodiment 2

[0053] A kind of preparation method of chitosan copolymer water treatment agent, comprises the steps:

[0054] Weigh 3.2g of chitosan, measure 100mL of distilled water in a three-neck flask, add 2.1g of benzaldehyde-ethanol solution dropwise to the flask under nitrogen protection, and stir at 60°C for 12h. The formed pale yellow precipitate was washed three times with distilled water, and dried in a vacuum oven at 60° C. for 24 h to obtain chitosan-benzaldehyde Schiff base. 2.66g of chitosan-benzaldehyde and 0.1g of ammonium persulfate were dissolved in 100mL of 1% acetic acid solution. Under the protection of nitrogen, the mixture was stirred at 80° C. for 0.5 h, then 2.16 g of acrylic acid solution was added dropwise, and the reaction was continued for 6 h. The product was precipitated with 200 mL of acetone, the precipitate was washed with absolute ethanol and filtered three times, and dried at 60 °C for 1 h to obtain O-carboxyethyl-benzaldehyde chitosan Schiff base. Acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com