Carbon dioxide composite solvent and method for dissolving cellulose

A technology for dissolving cellulose and carbon dioxide, applied in the field of chemistry and materials, to achieve the effect of improving concentration and stability, low temperature and pressure requirements, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

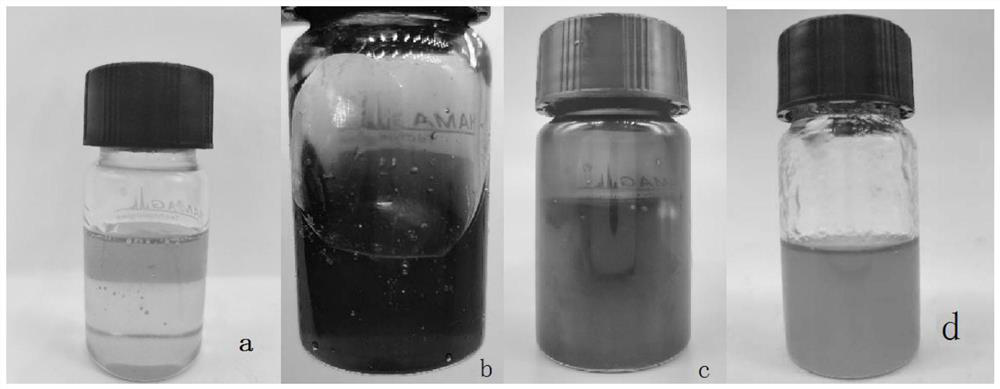

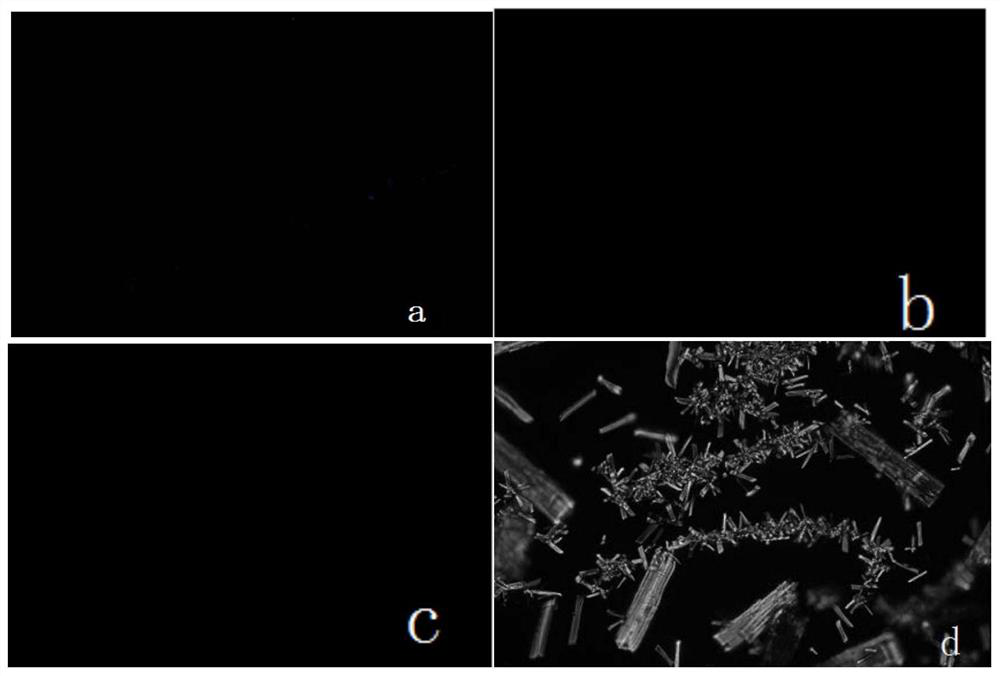

Embodiment 1

[0024] A carbon dioxide complex solvent, including 10.00g DMSO, 1.91g DBU and 1.00g propylene carbonate (PC), CO 2 Henry's constant in PC is 0.68×10 7 Pa. Dissolve 0.68g of pulp cellulose (DP=755) in the carbon dioxide composite solvent, pass through 0.5MPa carbon dioxide, and activate and dissolve at 50°C to obtain a cellulose solution with a cellulose concentration of 5wt%. In this solution, DBU and fiber The molar ratio of prime anhydroglucose unit AGU is 3:1.

Embodiment 2

[0026] A carbon dioxide complex solvent, including 10.00g DMSO, 2.55g DBN and 2.00g propylene carbonate (PC), CO 2 Henry's constant in PC is 0.68×10 7 Pa. Dissolve 1.10g of pulp cellulose (DP=755) in the carbon dioxide composite solvent, pass through 0.3MPa carbon dioxide, and activate and dissolve at 40°C to obtain a cellulose solution with a cellulose concentration of 7wt%. In this solution, DBN and AGU The molar ratio is 3:1.

Embodiment 3

[0028] Dissolve pulp cellulose (DP=755) (2.10g) in a carbon dioxide composite solvent of DMSO (10.00g), DBU (5.92g) and SF (3.00g), and CO 2 The Henry constant in SF is 0.86×10 7 Pa. Then, 0.6MPa carbon dioxide was introduced to activate dissolution at 60° C. to obtain a cellulose solution with a cellulose concentration of 10 wt %, and the molar ratio of DBU to AGU in the solution was 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com