Coke containing domestic waste incineration ash and preparation method thereof

A technology for incinerating ash and ash, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of increased disposal costs, etc., and achieve the effects of facilitating consumption and utilization, simple preparation methods, and easy large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

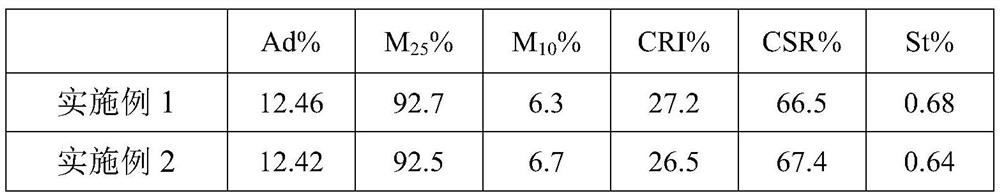

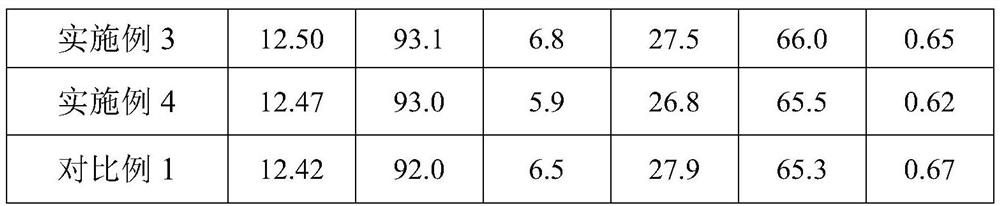

[0036] Example 1-4: Preparation of Metallurgical Coke Containing Municipal Waste Incineration Ash

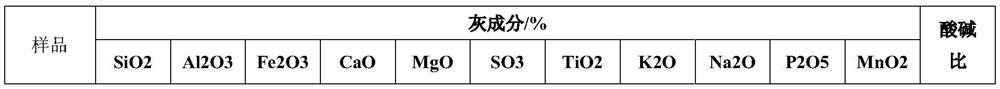

[0037]Take the ash after incineration of a garbage dump in a city, and analyze the ash composition. According to the form of oxides, K 2 O is 0.09%, Na 2 O is 0.45%, CaO is 0.21%, Fe 2 O 3 0.33%, MgO 0.09%, SiO 2 is 52.2%; Al 2 O 3 42.7%; TiO 2 2.3%, other 1.63%.

Embodiment 1

[0039] The above-mentioned ash and slag are screened and crushed, and the ash and slag particles with a particle size larger than 3 mm and other incomplete combustion impurities are crushed to make them all become ash and slag with a particle size of less than 3 mm for use.

[0040] The various components of the cleaned coal with the Hastelloy grindability index <60 and the proportion of the original particle size less than 3mm <60% are separately pre-pulverized, so that the proportion of particles with a particle size larger than 3mm is ≥85% before use.

[0041] The coal is blended according to the following mass percentages: 0.1% ash, gas coal 17%, gas fat coal 20%, 1 / 3 coking coal 18%, coking coal 7%, fat coal 16%, lean coal 8%, lean coal 14% ; And uniformly mixed to obtain blended coal; then crushed to obtain blended coal with a particle size of less than 3mm, accounting for 89.5% of its total mass;

[0042] After tamping, it is sent to the tamping coke oven for coking, an...

Embodiment 2

[0044] The above-mentioned ash and slag are screened and crushed, and the ash and slag particles with a particle size larger than 3 mm and other incomplete combustion impurities are crushed to make them all become ash and slag with a particle size of less than 3 mm for use.

[0045] The various components of the cleaned coal with the Hastelloy grindability index <60 and the proportion of the original particle size less than 3mm <60% are separately pre-pulverized, so that the proportion of particles with a particle size larger than 3mm is ≥85% before use.

[0046] Coal blending according to the following mass percentages: 0.3% ash, gas coal 15%, gas fat coal 21%, 1 / 3 coking coal 18%, coking coal 6%, fat coal 20%, lean coal 10%, lean coal 10% ; and uniformly mixed to obtain blended coal; then crushed to obtain blended coal with a particle size of less than 3mm, accounting for 90.2% of its total mass;

[0047] After tamping, it is sent to the tamping coke oven for coking, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com