Heat exchanger controlled by cooperative communication of liquid level vibration

A collaborative communication and heat exchanger technology, applied to indirect heat exchangers, heat exchanger types, vibration cleaning, etc., can solve the problems of low intelligence and poor vibration heat exchange effect, and achieve enhanced heat transfer and good Descaling and heat exchange effect, effect of improving heat utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

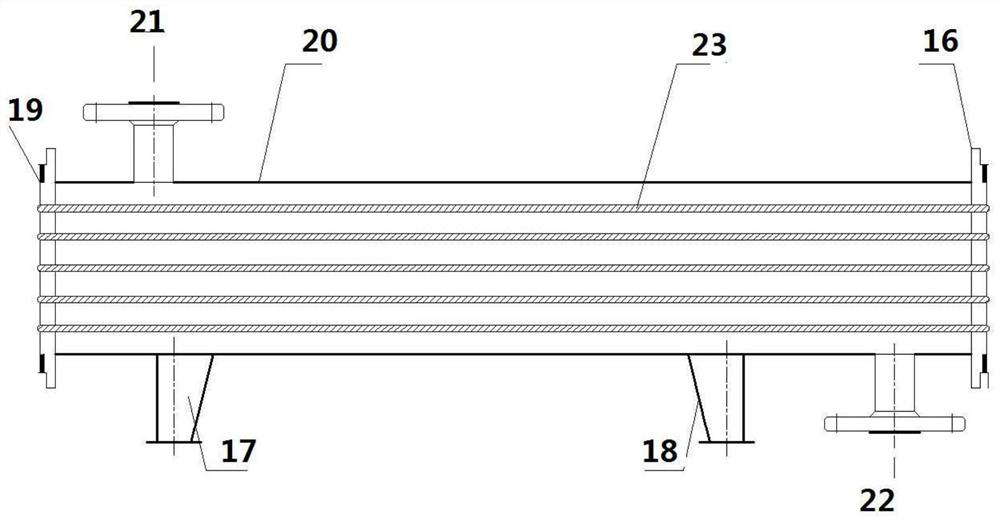

[0033] A pipe shell heat exchanger, such as figure 1 Shown, the shell and tube heat exchanger comprises a housing 20, heat exchange component 23, the shell inlet nozzle 21 and outlet nozzle of the shell 22; in the housing 20, the heat exchanger heat transfer member 23 disposed member tube plate 16 is fixedly connected to the front, rear tube plate 19; the shell of the inlet nozzle 21 and outlet nozzle shell 22 are provided on the housing 20; takeover fluid inlet 21 enters from the shell, through the heat exchanger means for heat, took 22 out of the shell side exit.

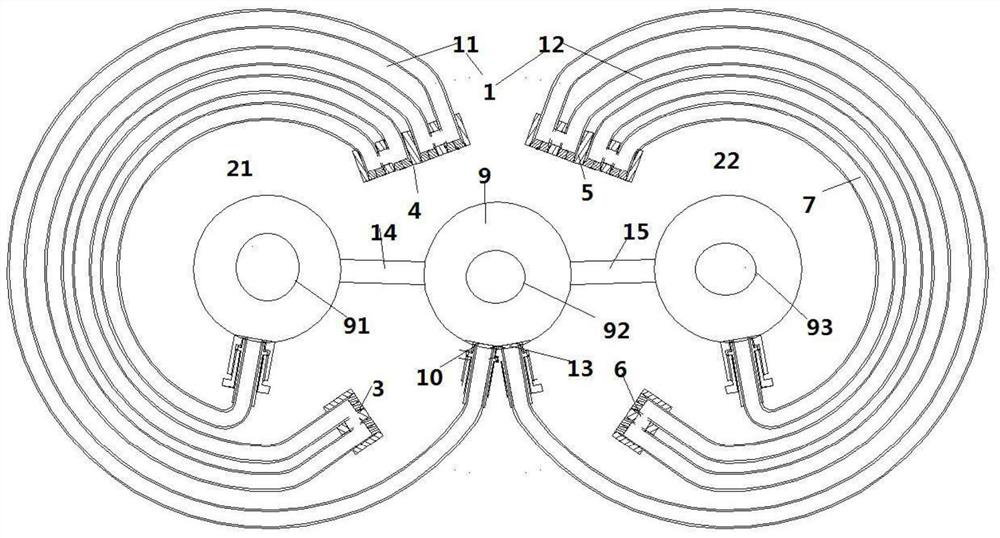

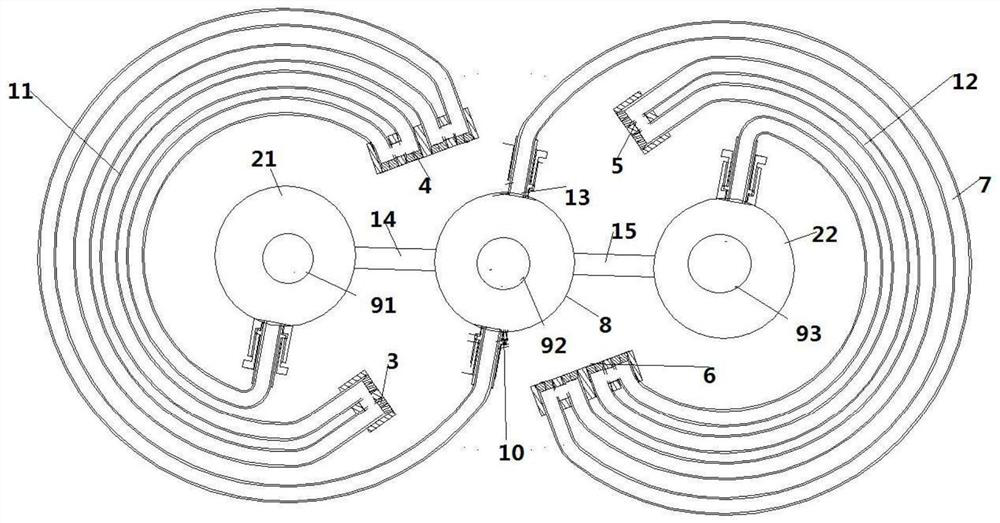

[0034] Advantageously, Figure 2-1 Heat transfer member extending in the horizontal direction. A heat exchanger disposed in the horizontal direction.

[0035] Figure 2 shows a top view of the heat exchange component 23, shown in Figure 2, the heat exchanger comprising a group member 1 includes a left tube group pipe 8, the left side of tube 21, tube 22, and a right tube group, said tube 11, and right tube group 12, lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com