Zinc-cadmium electric heating smelting rotary kiln

A rotary kiln and electric heating technology, applied in the field of metallurgy, can solve the problems of high consumption of chemical auxiliary materials, large investment per unit output, strong raw material selectivity, etc., and achieve the effect of improving condensation effect, improving service life, and evenly splashing droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

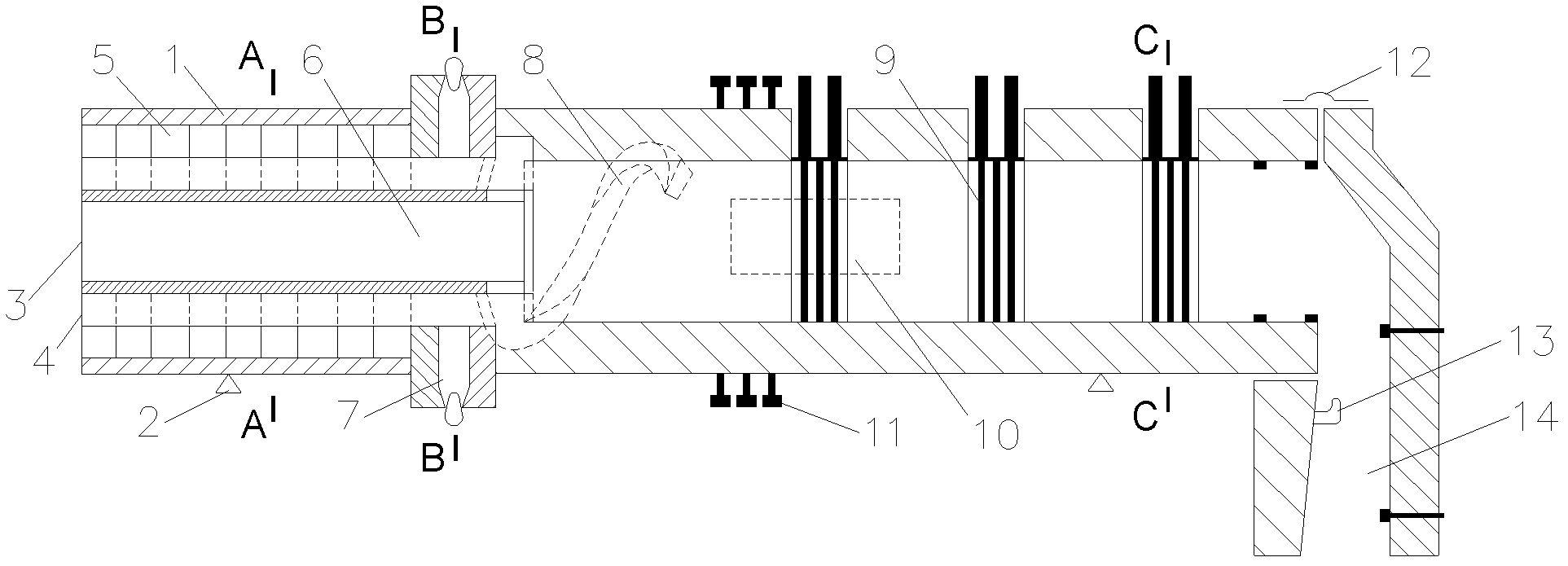

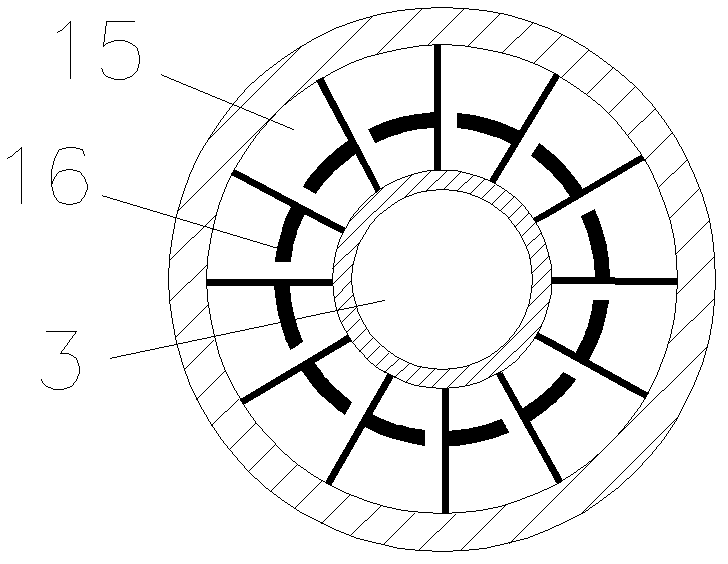

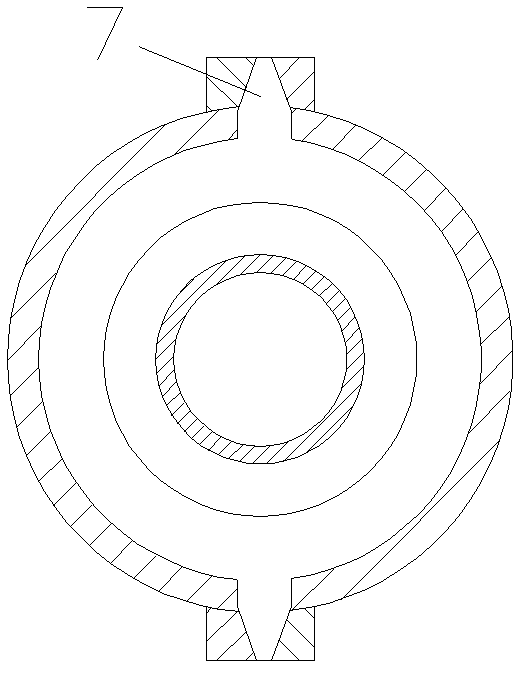

[0016] Example 1. Such as figure 1 As shown, the kiln body 1 is included, and there is a kiln body transmission device 2 at the bottom of the kiln body 1, through which the kiln body transmission device 2 can drive the kiln body 1 to rotate slowly and continuously at an average speed during the smelting process. Kiln body 1 is lined with silicon carbide bricks plus lightweight insulation bricks. The front end of the kiln body 1 is provided with a feed port 3 and an exhaust port 4, the feed port 3 is connected to the feed hopper 17, and the exhaust port 4 is connected to the bag filter. The material is fed into the kiln body 1 from the feed hopper 17 through the feed port 3, and the steam is discharged out of the kiln body 1 through the chimney after preheating the added material through the feed port 3. The exhaust gas produced by smelting is further dissipated in the preheating section (preheating drum 6), and then discharged out of the kiln body 1 through the exhaust port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com