Method for displaying metallographic structure of platinum

A metallographic structure and obvious technology, which is applied in the field of microstructure analysis of metal materials, can solve the problems of serious volatilization of concentrated nitric acid and concentrated hydrochloric acid, difficulty in controlling the corrosion rate, and great harm to operators, so as to achieve stable and reliable corrosion process and easy promotion , the effect of stabilizing the corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

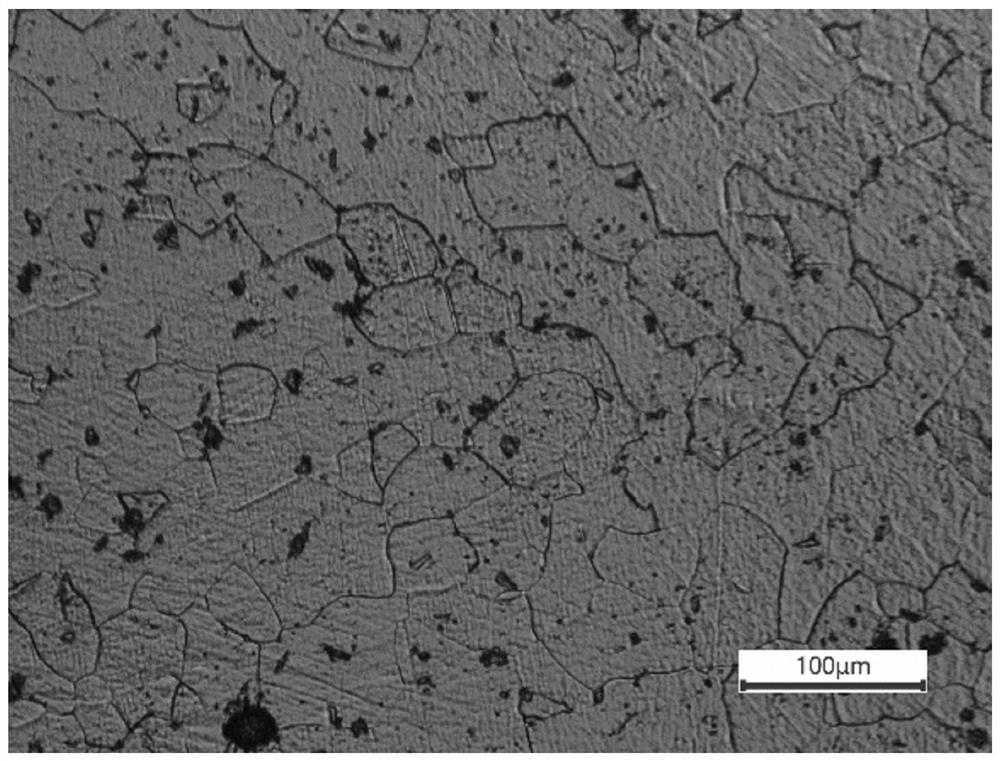

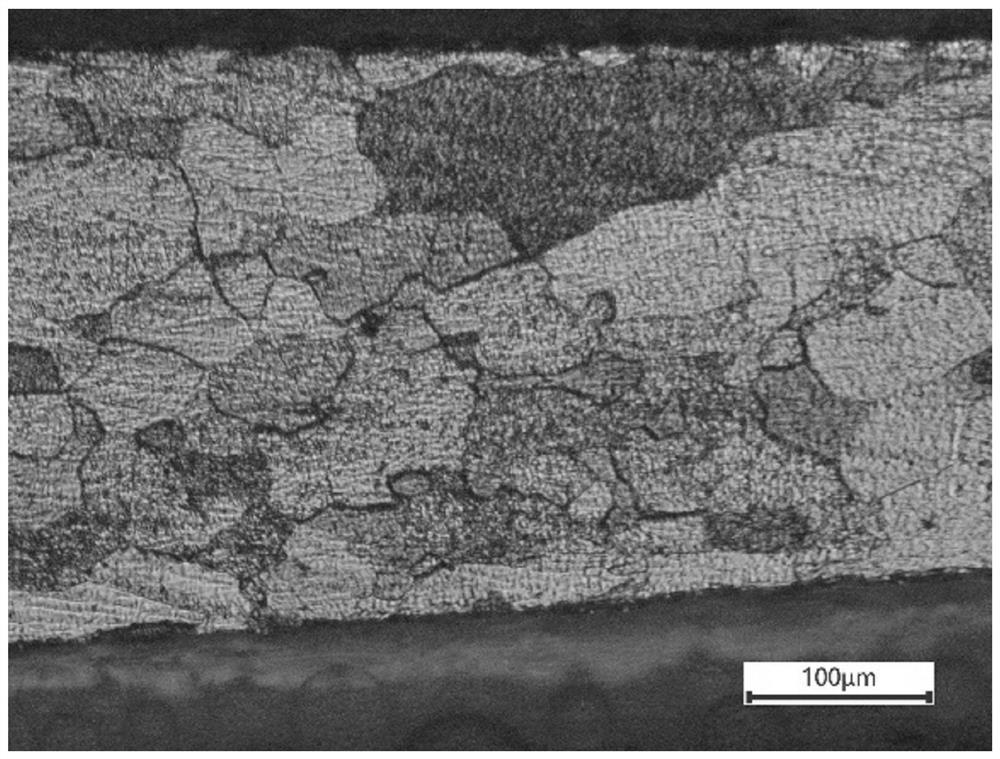

[0032] A method for displaying the metallographic structure of platinum, comprising the steps of:

[0033] 1) Mosaic

[0034] Take a cubic platinum sample, select the metallographic observation surface of the platinum sample, and inlay and fix the platinum sample so that the metallographic observation surface of the platinum sample is close to the bottom of the metallographic soft rubber mosaic mould;

[0035] 2) Grinding and polishing

[0036] Take out the inlaid platinum sample from the metallographic soft rubber inlay mold, and use a metallographic grinder to grind the metallographic observation surface of the platinum sample. During the grinding process, the metallographic grinder rotates at a speed of 250 r / min to 600 r / min , sequentially use 400#, 800#, 1000# metallographic sandpaper to polish, the grinding direction and the old scratch direction form 90° during the grinding process, especially note that once the grinding marks produced by the metallographic sandpaper u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com