Recycling method and recycling equipment for positive electrode active material of lithium ion battery

A positive active material, lithium-ion battery technology, applied in the direction of battery recycling, positive electrode, active material electrode, etc., can solve the problems of high cost, low recovery rate, low metal separation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

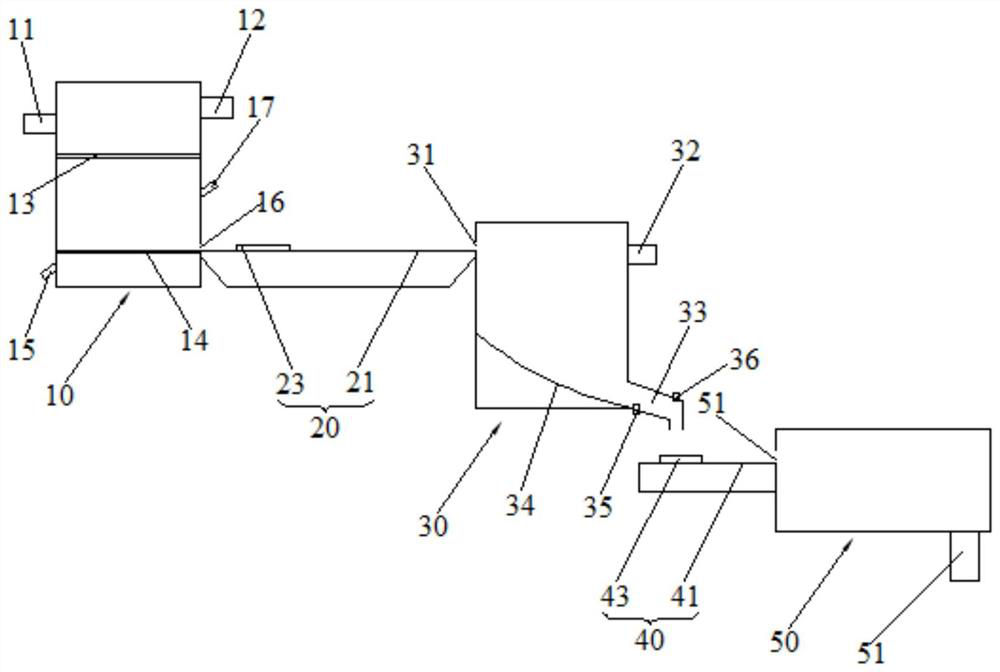

Image

Examples

Embodiment 1

[0037] A method for recovering nickel-cobalt lithium manganate ternary positive electrode active material, comprising steps:

[0038] (1) Soak the scrapped nickel-cobalt-lithium-manganese-oxide positive electrode sheet (the positive electrode sheet includes the scrapped nickel-cobalt-lithium-manganese-oxide active material, PVDF binder and Super-P conductive agent) in NMP, and heat at 70°C for 1h The binder PVDF in the positive electrode sheet is dissolved in NMP, filtered, and then dried at 110°C to obtain a waste material containing nickel cobalt lithium manganese oxide and a conductive agent;

[0039] (2) Add LiNO with a molar ratio of 3:2 to the waste material 3 and LiOH eutectic lithium salt, mixed evenly, sintered in a sintering furnace at 300°C for 3 hours to repair lithium, and then calcined at 850°C for 4 hours to obtain nickel cobalt lithium manganate active material.

[0040] The repaired nickel-cobalt lithium manganese oxide active material was tested for the firs...

Embodiment 2

[0042] The recovery method of lithium manganate cathode active material comprises steps:

[0043] (1) Soak the scrapped lithium manganate positive electrode sheet (the positive electrode sheet includes the scrapped lithium manganate active material, PVDF binder and acetylene black conductive agent) in NMP, heat at 70°C for 1h to make the positive electrode sheet The binder PVDF is dissolved in NMP, filtered, and then dried at 110°C to obtain a waste material containing lithium manganate and a conductive agent;

[0044] (2) Add LiNO with a molar ratio of 1:1 to the waste material 3 and LiOH eutectic lithium salt, mixed evenly, sintered in a sintering furnace at 280°C for 4 hours to repair lithium, and then calcined at 850°C for 4 hours to obtain lithium manganate active material.

[0045] The repaired lithium manganate active material was tested for the first discharge specific capacity and the first charge-discharge efficiency with reference to the same method as in Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com