Impeller lotus leaf drainage decompression casting system and casting process thereof

A casting system and casting process technology, applied in the field of impeller casting, can solve problems such as impeller production process defects, and achieve the effects of enhancing the scour resistance of high temperature and high pressure airflow, avoiding scouring time, and enhancing scouring ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a detailed description of the embodiments of the present invention. The specific casting process methods not indicated in the following implementations are carried out by the enterprise in accordance with the international foundry standards and the program files formulated by the IOS9001 passed by the enterprise. Unless otherwise defined or stated, All professional and scientific terms used herein have the same meanings as those familiar to those skilled in the art of foundry engineering.

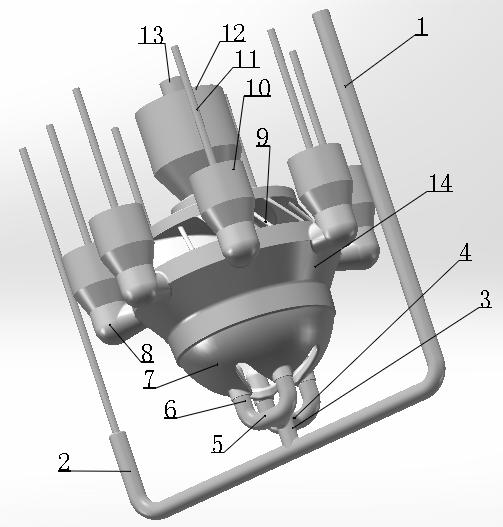

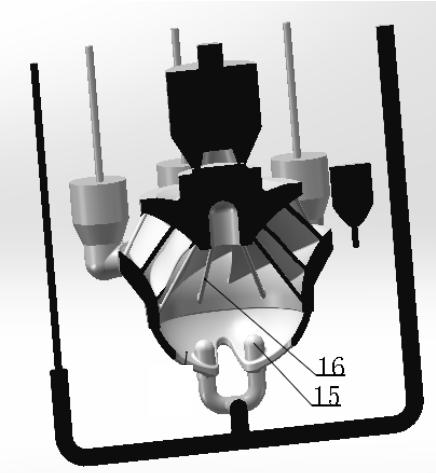

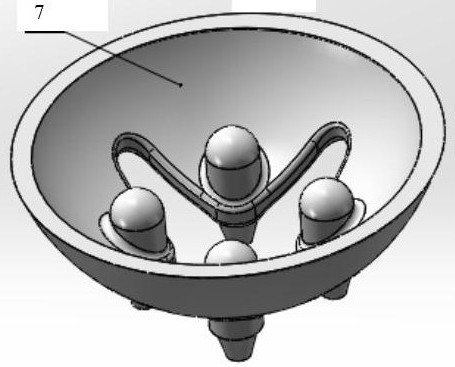

[0034] Such as Figure 1-7 , an impeller lotus leaf drainage and decompression casting system, including a casting body 14, the lower end of the casting body 14 is provided with a drainage and decompression gate 7, and the inner wall of the drainage and decompression gate 14 is provided with four inner runners Buffer risers 15, each of the ingate buffer risers 15 is connected to the ingate 6 respectively, every two ingates 6 are connected to the U-shaped ingate split...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com