Method for improving flaw detection qualification rate of low-carbon, low-aluminum and high-chromium forging round steel

A pass rate and round forging technology, which is applied in forging, smelting of ferritic heat-resistant steel, and pouring fields, can solve the problems of low pass rate and achieve the effects of improving quality, reducing central cracks, and increasing compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

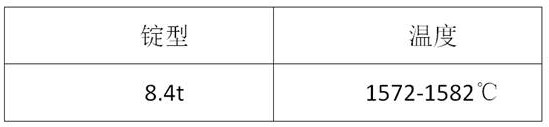

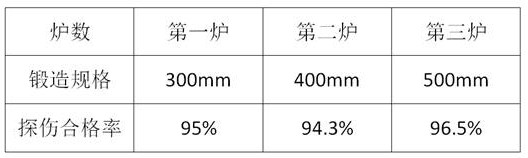

[0011] 80 tons were smelted at one time, using electric furnace smelting + LF furnace refining + VD degassing process to smelt and cast three furnaces. After upsetting and drawing forging, the pass rate of flaw detection has been greatly improved. The details are as follows:

[0012] Electric furnace smelting part:

[0013] 1. Use strong oxidation operation to reduce the content of gas and inclusions in steel. End point C, P control target C ≤ 0.05%, P ≤ 0.008%. Electric furnace tapping temperature: T≥1750℃. It is strictly forbidden to drop slag when tapping.

[0014] 2. Put the synthetic slag and alloy into the bag online, and the alloy should be baked for more than 30 minutes.

[0015] 3. During the tapping process of the electric furnace, 150Kg of aluminum deoxidizer is added along with the steel flow.

[0016] Refining part of LF furnace:

[0017] 1. When the temperature T≥1560℃, add 200kg of silicon-calcium powder to the slag to make reduced slag. After adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com