Preparation method and application process of eucommia wooden barrel for wine making

A technology of eucommia wood and wooden barrels, which is applied in the field of preparation of eucommia wooden barrels for winemaking. It can solve the problems of long growth and production cycles, single main flavor components, and limited changes in the flavor of stored wine, so as to achieve good airtightness and strong wine body. Effects of clean flavor and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

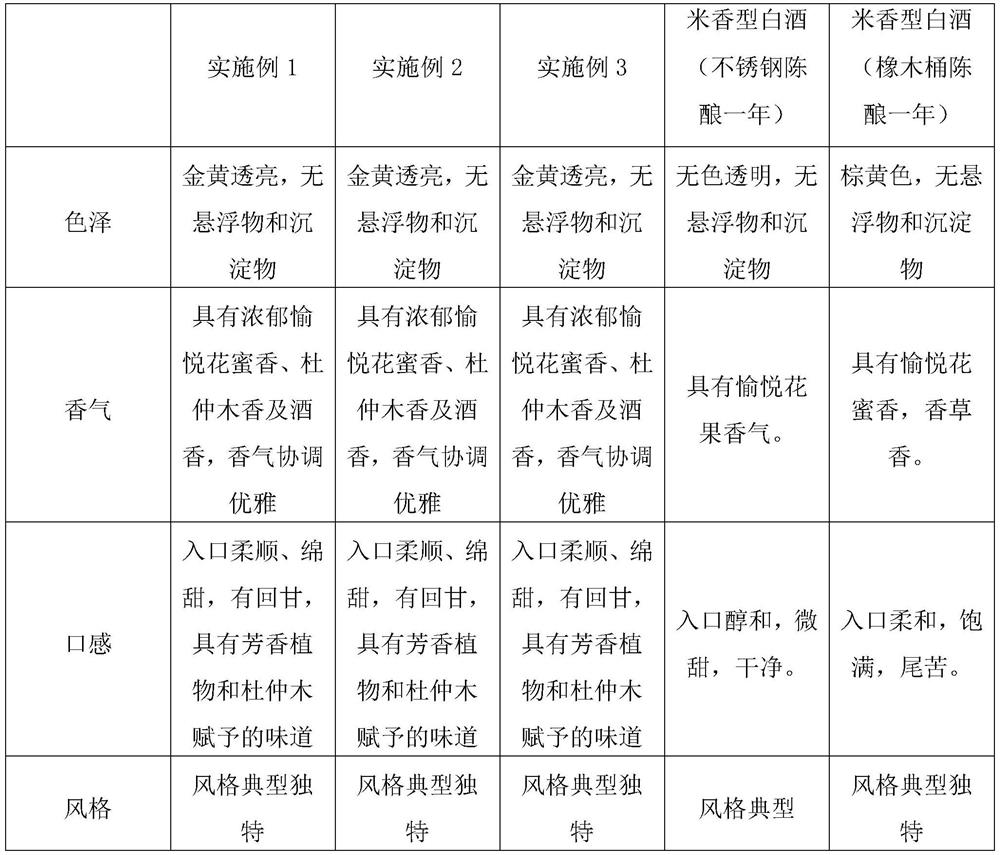

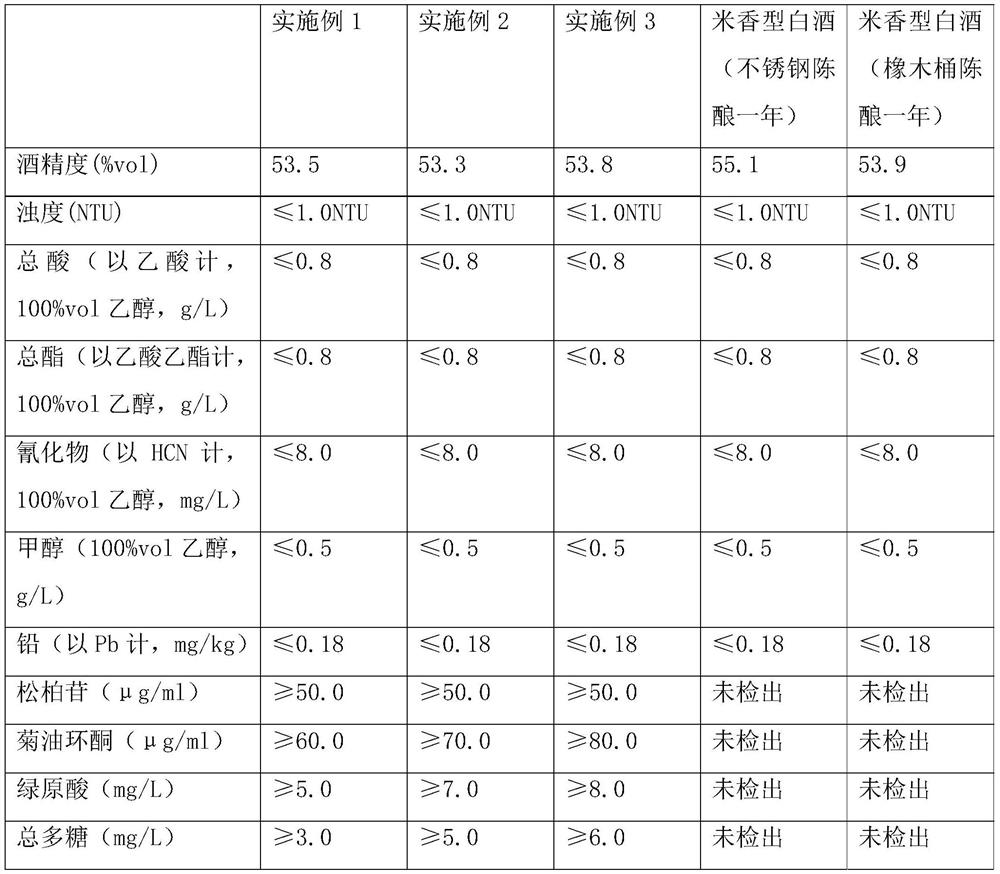

Embodiment 1

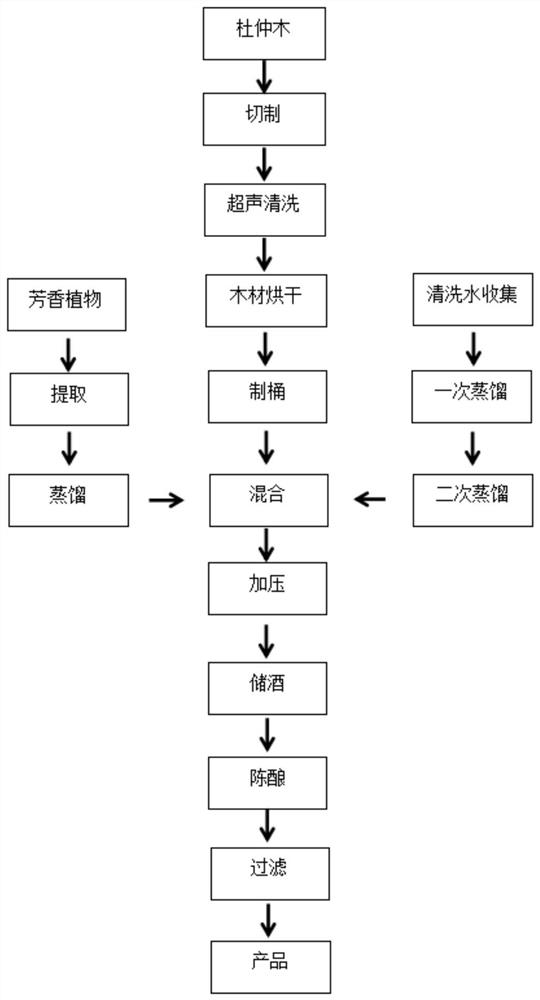

[0029] refer to figure 1 Shown, a kind of preparation method and application technology of eucommia wooden barrel for brewing, comprises the following steps:

[0030] (1) Timber selection: use eucommia wood with a growth period of more than 5 years as raw material, select eucommia logs without obvious nodules, separate the bark through special mechanical equipment, and cut the logs longitudinally into length, width and thickness respectively 90 cm, 7 cm, 4 cm long strips, cut into 25 to 28 pieces;

[0031] (2) Wood pre-treatment: Put long strips of wood in an ultrasonic cleaning machine, add 200L of pure water to soak, the mass ratio of eucommia wood and cleaning pure water is 1:2, set the frequency to 30KHz, and set the temperature to 30°C for a single run The time is 120 minutes, and it runs twice, which can effectively remove the residual tannin in the board. The wood after ultrasonic cleaning is placed in an oven at 50°C for heat treatment. After heating for 24 hours, tak...

Embodiment 2

[0038] refer to figure 1 Shown, a kind of preparation method and application technology of eucommia wooden barrel for brewing, comprises the following steps:

[0039] (1) Timber selection: use eucommia wood with a growth period of more than 5 years as raw material, select eucommia logs without obvious nodules, separate the bark through special mechanical equipment, and cut the logs longitudinally into length, width and thickness respectively 90 cm, 7 cm, 4 cm long strips, cut into 25 to 28 pieces;

[0040](2) Wood pre-treatment: Put long strips of wood in an ultrasonic cleaning machine, add 200L of pure water to soak, the mass ratio of eucommia wood and cleaning pure water is 1:2, set the frequency to 30KHz, and set the temperature to 30°C for a single run The time is 120 minutes, and it runs twice, which can effectively remove the residual tannin in the board. The wood after ultrasonic cleaning is placed in an oven at 50°C for heat treatment. After heating for 24 hours, take...

Embodiment 3

[0047] refer to figure 1 Shown, a kind of preparation method and application technology of eucommia wooden barrel for brewing, comprises the following steps:

[0048] (1) Timber selection: use eucommia wood with a growth period of more than 5 years as raw material, select eucommia logs without obvious nodules, separate the bark through special mechanical equipment, and cut the logs longitudinally into length, width and thickness respectively 90 cm, 7 cm, 4 cm long strips, cut into 25 to 28 pieces;

[0049] (2) Wood pre-treatment: Put long strips of wood in an ultrasonic cleaning machine, add 200L of pure water to soak, the mass ratio of eucommia wood and cleaning pure water is 1:2, set the frequency to 30KHz, and set the temperature to 30°C for a single run The time is 120 minutes, and it runs twice, which can effectively remove the residual tannin in the board. The wood after ultrasonic cleaning is placed in an oven at 50°C for heat treatment. After heating for 24 hours, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com